Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | GE IS215VAMBH1A |

| Manufacturer | General Electric (GE) |

| Product Category | VME Analog Input Module |

| Series | Mark VI Speedtronic |

| Input Channels | 8 differential analog input channels |

| Input Signal Types | 4-20mA, 0-10V DC, thermocouple (Type J/K/T), RTD (Pt100) |

| ADC Resolution | 16-bit |

| Accuracy | ±0.1% of full scale (FS) for 4-20mA/0-10V; ±0.2% FS for thermocouple/RTD |

| Communication Interface | Mark VI VME backplane + 1x IONet 10Base2 (BNC) |

| Operating Temperature Range | -40°C to +70°C |

| Power Supply | +5V DC / ±15V DC (VME bus standard) |

| Installation Method | Mark VI standard VME 6U chassis slot mounting |

| Safety Certifications | CE, UL 508, IEC 61010-1 |

| Physical Size | 10.16 cm (W) × 22.86 cm (H) × 12.7 cm (D) |

| Product Origin | USA |

| Warranty Period | 12 months |

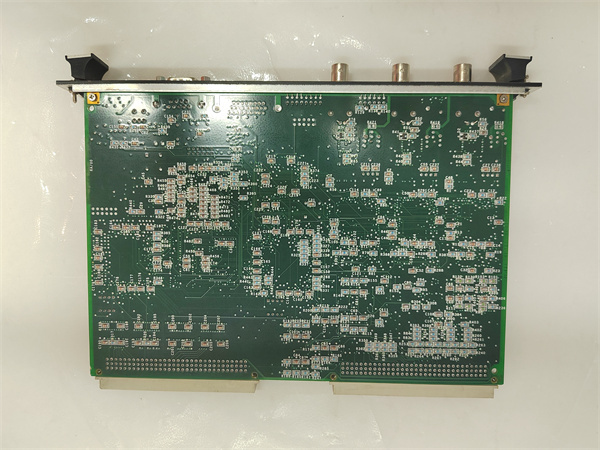

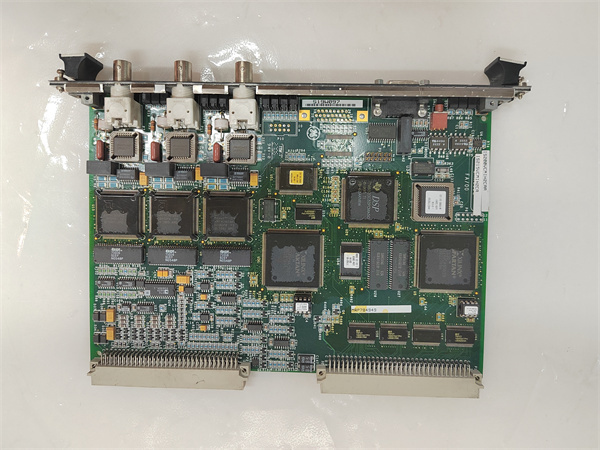

GE IS215VAMBH1A

Product Introduction

The GE IS215VAMBH1A is a high-precision VME analog input module belonging to GE’s Mark VI Speedtronic series, specifically engineered for industrial control systems requiring accurate acquisition of analog process parameters. As a key front-end component in Mark VI-based architectures, it converts continuous analog signals from field sensors (such as temperature, pressure, and flow sensors) into digital data, then transmits this data to the main controller via the VME backplane and IONet network—ensuring reliable and timely feedback for critical control loops.

Equipped with 8 differential analog input channels and 16-bit ADC resolution, the GE IS215VAMBH1A delivers exceptional measurement accuracy across multiple signal types, including 4-20mA current loops, 0-10V voltages, thermocouples, and RTDs. Its hardware design integrates built-in signal conditioning and isolation, eliminating the need for external signal converters and enhancing noise immunity. In practical applications, the GE IS215VAMBH1A acts as the “sensory nerve” of the Mark VI system, enabling precise monitoring of process variables and laying the foundation for stable and efficient industrial operations.

Core Advantages and Technical Highlights

High-Precision Signal Acquisition

The GE IS215VAMBH1A features a 16-bit analog-to-digital converter (ADC) and achieves an accuracy of ±0.1% FS for 4-20mA/0-10V signals, and ±0.2% FS for thermocouple/RTD measurements. This high precision ensures that even subtle changes in process parameters (such as a 0.1°C temperature fluctuation in a turbine bearing or a 0.01mA current drift in a flow sensor) are accurately captured. The module’s differential input design further suppresses common-mode noise, making it suitable for industrial environments with high electromagnetic interference—critical for applications like gas turbine exhaust temperature monitoring where measurement precision directly impacts combustion efficiency and equipment safety.

Multi-Sensor Compatibility

With 8 configurable differential channels, the GE IS215VAMBH1A supports a wide range of industrial sensors: 4-20mA current loops for pressure/flow transmitters, 0-10V DC for level sensors, Type J/K/T thermocouples for high-temperature measurements (up to 1200°C), and Pt100 RTDs for precise temperature monitoring (up to 600°C). Each channel can be independently configured via GE’s Proficy Machine Edition software, eliminating the need for hardware jumpers and simplifying on-site commissioning. This versatility makes the module a one-stop solution for mixed-signal acquisition scenarios, such as petrochemical refineries where a single module can monitor reactor temperature (thermocouple), feed pressure (4-20mA), and liquid level (0-10V).

Robust Isolation & Environmental Durability

The GE IS215VAMBH1A incorporates 2kVrms channel-to-channel isolation and 500Vrms isolation between inputs and the backplane, effectively preventing ground loops and voltage transients from damaging the module or distorting signals. Its operating temperature range of -40°C to +70°C and conformal-coated circuit boards ensure reliable performance in harsh environments—from freezing offshore platforms to high-temperature turbine halls. Additionally, the module’s EMC design complies with IEC 61000-4 standards, resisting interference from nearby motors, inverters, and high-voltage equipment—ensuring stable data acquisition even in electrically noisy industrial settings.

Typical Application Scenarios

Gas Turbine Temperature & Pressure Monitoring

In combined-cycle power plants, the GE IS215VAMBH1A is deployed to monitor critical gas turbine parameters. It connects 4 Type K thermocouples to measure exhaust gas temperature (EGT) at different turbine stages, 2 Pt100 RTDs for bearing temperature monitoring, and 2 4-20mA pressure transmitters for fuel gas pressure and lubricating oil pressure. The module converts these analog signals into digital data, then transmits it via the VME backplane to the Mark VI main controller. This data enables the controller to adjust fuel injection and cooling systems in real time, preventing turbine overheating and ensuring optimal combustion efficiency. The module’s high accuracy and isolation are crucial for avoiding false alarms and ensuring turbine safety during peak load operation.

Petrochemical Reactor Process Control

In petrochemical refinery reactor systems, the GE IS215VAMBH1A serves as the core analog acquisition module. It uses 3 4-20mA input channels to monitor reactor pressure, catalyst flow rate, and hydrogen partial pressure; 2 Type T thermocouples for reactor inlet/outlet temperature; and 3 0-10V channels for liquid level in auxiliary tanks. The module’s differential inputs and noise suppression ensure accurate data acquisition even in the presence of interference from nearby pumps and compressors. The digital data is transmitted via IONet to the central SCADA system, allowing operators to adjust reactor conditions (such as pressure and temperature) to maintain product quality and prevent hazardous overpressure events. Its multi-sensor compatibility reduces the number of modules needed, simplifying system architecture and lowering costs.

GE IS215VAMBH1A

Related Model Recommendations

GE IS215VCMIH2B: A VME bus master controller that pairs with the GE IS215VAMBH1A to process and transmit analog data to the Mark VI system.

GE IS215VPROH2B: A communication module that works with the GE IS215VAMBH1A to relay analog data to upper-level SCADA/MES systems via Modbus TCP.

GE IS220UCSAH1A: A supplementary analog input module with 16 channels, expanding the system’s analog acquisition capacity when used with the GE IS215VAMBH1A.

GE IS220PVIBH1A: A vibration monitoring module that complements the GE IS215VAMBH1A by adding machinery health data to the control system.

GE IS220PCAAH1A: A VME bus power supply module that provides stable ±15V DC/+5V DC power to the GE IS215VAMBH1A.

GE IS215VAMBH2A: An upgraded version of the GE IS215VAMBH1A with 16 input channels and 24-bit ADC resolution, for high-density, ultra-precision applications.

GE IS220YDIAS1A: A digital input module that works with the GE IS215VAMBH1A to integrate discrete status signals (e.g., sensor alarms) into the control system.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the GE IS215VAMBH1A, power off the Mark VI VME chassis and ensure the workspace is ESD-protected (grounded mats/wristbands). Required tools include a Phillips screwdriver, multimeter, torque wrench (0.5 N·m), and wire stripper. Verify the chassis slot supports VME 6U standards and that the power supply provides ±15V DC/+5V DC. Align the module’s edge connectors with the slot guides, insert firmly until seated, and secure with front-panel screws. For wiring, use shielded twisted-pair cables for analog inputs (max length 100 meters for 4-20mA, 50 meters for thermocouples/RTDs), and connect the cable shield to the chassis ground. Configure channel parameters (signal type, range) via Proficy Machine Edition before powering on.

Maintenance Suggestions

Conduct monthly inspections of the GE IS215VAMBH1A to check LED statuses (Power, Fault, Channel Activity) and wiring connections—focus on thermocouple/RTD terminals for corrosion. Calibrate the module semi-annually using a precision signal generator (e.g., 4-20mA/0-10V calibrator, temperature bath for thermocouples) to maintain accuracy. Clean the module’s ventilation slots quarterly with compressed air (≤0.5MPa). If a fault occurs, first check sensor wiring and signal integrity with a multimeter; use Proficy Machine Edition to view channel-specific diagnostic logs. Replace with genuine GE spares (lead time 2-3 days) and reconfigure channel parameters to match the original setup—restoring operation quickly.

Service and Guarantee Commitment

The GE IS215VAMBH1A comes with a 12-month manufacturer’s warranty covering defects in materials and workmanship. GE’s global technical support team provides 24/7 assistance via email and online portals, offering guidance on calibration, channel configuration, and troubleshooting. For critical applications, certified GE engineers can be dispatched to customer sites within 48 hours in major industrial regions.

Extended warranty plans up to 3 years are available, including annual preventive maintenance and calibration checks. GE also offers customized training on analog signal acquisition and GE IS215VAMBH1A integration with Mark VI systems. With decades of expertise in industrial control and sensor data acquisition, GE stands behind the reliability of the GE IS215VAMBH1A and is committed to supporting customers throughout the product’s lifecycle.