Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

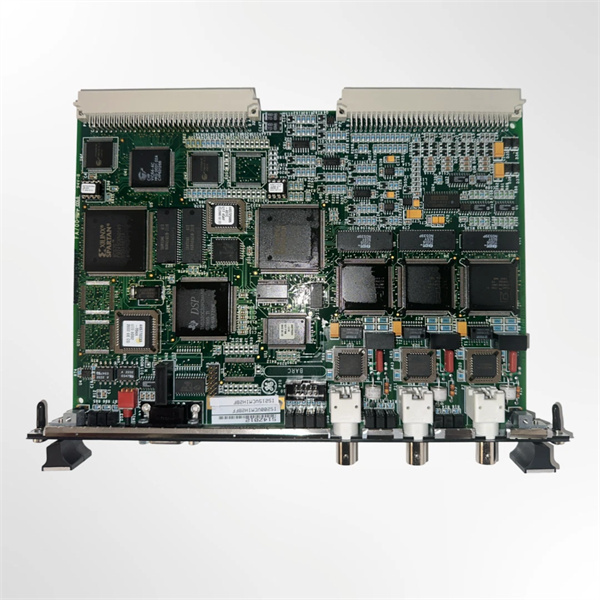

| Product Model | GE IS215VCMIH1B |

| Manufacturer | General Electric (GE) |

| Product Category | VME Bus Master Controller/Communication Interface Module |

| Series | Mark VI Speedtronic |

| Processor | Texas Instruments TMS320C32 32-bit DSP |

| Memory | 32 KB Dual-Port SRAM + 32 KB Flash |

| Communication Ports | 2x IONet 10Base2 Ethernet (BNC), 1x RS-232C (D-type) |

| Operating Temperature Range | -25°C to +60°C |

| Power Supply | +5V DC (VME bus standard) |

| Installation Method | Mark VI standard VME 6U chassis slot mounting |

| Safety Certifications | CE, UL 508 |

| Physical Size | 10.16 cm (W) × 22.86 cm (H) × 12.7 cm (D) |

| Product Origin | USA |

| Warranty Period | 12 months |

GE IS215VCMIH1B

Product Introduction

The GE IS215VCMIH1B is an earlier base model of VME bus master controller and communication interface modules in GE’s Mark VI Speedtronic series, specifically designed for entry-level to medium-scale industrial control applications such as turbine auxiliary control, small-to-medium process automation, and localized monitoring systems. As a foundational data exchange node in Mark VI-based control architectures, it establishes stable communication links between distributed I/O modules, control units, and the proprietary IONet network, ensuring timely transmission of control commands and process data for non-critical to semi-critical control loops.

Powered by the Texas Instruments TMS320C32 32-bit DSP, the GE IS215VCMIH1B delivers reliable signal processing capabilities, enabling smooth execution of basic to moderate control algorithms and steady data throughput. Its hardware design focuses on cost-effectiveness and essential functionality, with 32 KB Flash memory for storing core configuration data and firmware, and two IONet ports for simplified network deployment. This makes it suitable for deployment in industrial environments with stable conditions and the need for economical communication management. In practical applications, the GE IS215VCMIH1B acts as a reliable communication node for Mark VI systems, supporting the normal operation of auxiliary control loops and providing a cost-efficient solution for small-scale automation needs.

Core Advantages and Technical Highlights

IONet Configuration Flexibility

Equipped with two IONet 10Base2 Ethernet ports (BNC connectors) and one RS-232C port (D-type), the GE IS215VCMIH1B supports practical network configurations for entry-level to medium-scale control systems. The two IONet ports can be configured for basic redundancy (one active, one standby) or dedicated to separate I/O racks, meeting the reliability requirements of semi-critical control loops. The RS-232C port enables local configuration and debugging via GE’s Proficy Machine Edition software, facilitating on-site commissioning. The IONet protocol’s low-latency feature ensures control commands are transmitted within acceptable timeframes, which is essential for maintaining stable operation of turbine auxiliary equipment and small-scale process lines—ideal for applications where cost-efficiency and basic reliability are prioritized.

Balanced Environmental Adaptability

With an operating temperature range of -25°C to +60°C, the GE IS215VCMIH1B performs reliably in mild to moderate industrial environments, such as indoor control rooms and temperate-region industrial plants. Its circuit design adopts basic dust-proof and anti-interference measures, reducing the impact of common industrial contaminants and low-level electrical noise on module performance. The 32 KB Flash memory provides sufficient storage for essential control logic configurations and firmware, eliminating the need for external memory expansion in entry-level applications. The module’s EMC design complies with basic industrial standards, ensuring stable data transmission in environments with minimal electromagnetic interference from nearby equipment.

Practical Diagnostic Function

The GE IS215VCMIH2B integrates comprehensive LED indicators, including Status, Fail, Run, and individual IONet port activity lights (TX/RX/CD). These indicators provide clear real-time visual feedback on the module’s operational state, allowing maintenance personnel to quickly identify common issues. For example, an unlit port TX/RX light can signal a loose or faulty IONet cable connection, and a solid “Fail” LED may indicate a power supply anomaly or internal memory error. This intuitive diagnostic function simplifies daily maintenance work, reduces troubleshooting complexity, and helps shorten system downtime in case of minor faults—enhancing overall operational efficiency.

Typical Application Scenarios

Turbine Auxiliary Control Systems

In entry-level gas turbine auxiliary control systems of small-scale power plants, the GE IS215VCMIH1B serves as the key communication module. It connects to GE IS220UCSAH1A temperature/pressure input modules and GE IS220YDIAS1A digital input modules via IONet, collecting real-time data on lubricating oil pressure, cooling water temperature, and auxiliary pump status. This data is transmitted to the Mark VI auxiliary controller, which adjusts the operation of oil pumps and cooling fans. The two IONet ports enable basic redundant communication, ensuring uninterrupted data transmission if one port experiences temporary issues, while the RS-232C port allows on-site technicians to configure the module directly—supporting the stable operation of the turbine auxiliary system at a cost-efficient price point.

Small-to-Medium Chemical Process Lines

In small-to-medium chemical process lines (such as specialty chemical production), the GE IS215VCMIH1B facilitates localized data exchange between distributed I/O racks and the on-site control panel. It uses two IONet ports to connect to different sections—one for raw material mixing I/O and one for product quality testing sensors. This simplified segmented communication ensures data from each section is transmitted independently without congestion. The module relays process data to the on-site control panel, enabling operators to monitor and adjust parameters such as mixing time, temperature, and reagent dosage in real time. Its cost-effective design meets the budget constraints of small chemical enterprises, while reliable communication ensures consistent product quality in batch production processes.

GE IS215VCMIH1B

Related Model Recommendations

GE IS215VCMIH2B: The upgraded version of the GE IS215VCMIH1B with 64 KB Flash and 3 IONet ports, suitable for medium-to-large control systems with higher reliability needs.

GE IS215VCMIH1BE: A variant of the GE IS215VCMIH1B with RS-485 instead of RS-232C, ideal for systems needing long-distance field device communication.

GE IS215VCMIH1BF: A cost-sensitive variant with simplified firmware, designed for basic auxiliary control applications with minimal configuration needs.

GE IS215VCMIH2C: A high-performance upgraded model with 128 KB Flash and enhanced processing, tailored for large-scale turbine control systems.

GE IS220UCSAH1A: Analog input module that pairs with the GE IS215VCMIH1B to collect temperature, pressure, and flow data from field sensors.

GE IS220YDIAS1A: Digital input module that works with the GE IS215VCMIH1B to monitor equipment running status and switch signals.

GE IS220PCAAH1A: VME bus power supply module that provides stable +5V DC power to the GE IS215VCMIH1B and other chassis components.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the GE IS215VCMIH1B, power off the Mark VI VME chassis and ensure the workspace is equipped with ESD protection (grounded mats and wristbands). Required tools include a Phillips screwdriver, BNC cable tester, RS-232C cable tester, and torque wrench (set to 0.5 N·m). Verify the chassis slot conforms to 6U VME standards, then align the module’s edge connectors with the slot guides—avoid applying excessive force to prevent pin damage. Secure the module with front-panel screws, connect shielded BNC cables for IONet (max length 185 meters per segment), and use standard RS-232C cables for local configuration. Configure network parameters and basic control logic via GE’s Proficy Machine Edition software before powering on the system.

Maintenance Suggestions

Conduct monthly inspections of the GE IS215VCMIH1B to check LED statuses and cable connections, focusing on BNC and RS-232C connectors for corrosion or looseness. Clean the module’s ventilation slots quarterly using compressed air (pressure ≤0.5MPa) to remove dust buildup. For IONet communication issues, test cable continuity and check for network termination mismatches. If a fault is detected, use the LED indicators to isolate problems—e.g., a blinking “Run” LED may indicate a processor communication error with the backplane. For firmware updates, use only GE-authorized software to ensure compatibility. Replace with genuine GE spares (lead time 3-5 days) and restore configuration data from backups to minimize system downtime.

Service and Guarantee Commitment

The GE IS215VCMIH1B comes with a 12-month manufacturer’s warranty covering defects in materials and workmanship. GE’s global technical support team provides 24/7 assistance via email and online portals, offering expert guidance on installation, basic network configuration, and troubleshooting. For critical applications, certified GE engineers can be dispatched to customer sites within 48 hours in major industrial regions.

Extended warranty plans up to 3 years are available, including preventive maintenance checks to optimize module performance. GE also offers entry-level training programs on Mark VI system integration and GE IS215VCMIH1B configuration to help customers maximize the module’s operational value. With decades of expertise in industrial control, GE stands behind the reliability of the GE IS215VCMIH1B and is committed to supporting customers throughout the product’s lifecycle.