Description

Detailed Parameter Table

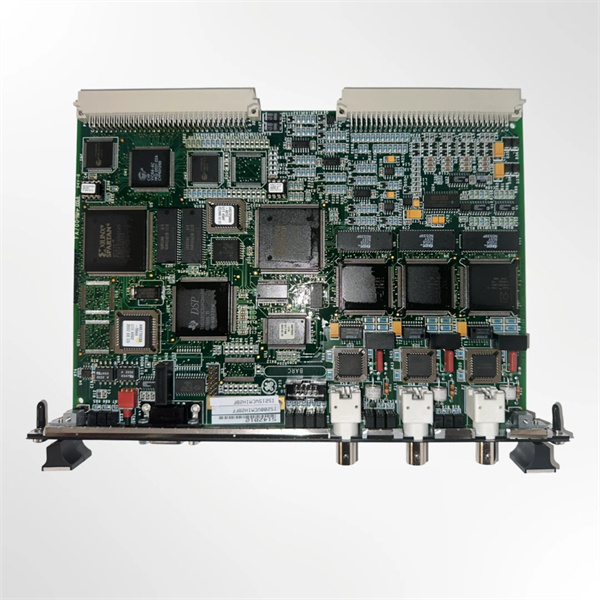

| Parameter Name | Parameter Value |

| Product Model | GE IS215VCMIH2BE |

| Manufacturer | General Electric (GE) |

| Product Category | VME Bus Master Controller/Communication Interface Module |

| Series | Mark VI Speedtronic |

| Processor | Texas Instruments TMS320C32 32-bit DSP |

| Memory | 32 KB Dual-Port SRAM + 64 KB Flash |

| Communication Ports | 2x IONet 10Base2 Ethernet (BNC), 1x RS-485 (D-type) |

| Operating Temperature Range | -35°C to +65°C |

| Power Supply | +5V DC (VME bus standard) |

| Installation Method | Mark VI standard VME 6U chassis slot mounting |

| Safety Certifications | CE, UL 508 |

| Physical Size | 10.16 cm (W) × 22.86 cm (H) × 12.7 cm (D) |

| Product Origin | USA |

| Warranty Period | 12 months |

GE IS215VCMIH2BF

Product Introduction

The GE IS215VCMIH2BE is a versatile VME bus master controller and communication interface module belonging to GE’s Mark VI Speedtronic series, specifically designed for industrial control applications such as turbine auxiliary control, medium-scale process automation, and distributed monitoring systems. As a key data exchange hub in Mark VI-based control architectures, it establishes stable communication links between distributed I/O modules, control units, the proprietary IONet network, and RS-485-based field devices, ensuring timely transmission of control commands and process data across the entire control system.

Powered by the Texas Instruments TMS320C32 32-bit DSP, the GE IS215VCMIH2BE delivers efficient signal processing capabilities, enabling smooth execution of control algorithms and data throughput. Its hardware design balances performance and cost-effectiveness, with expanded Flash memory for more configuration data and an RS-485 port for long-distance field device communication. This makes it suitable for deployment in industrial environments with relatively stable conditions, moderate electromagnetic interference, and the need for connecting remote sensors or actuators. In practical applications, the GE IS215VCMIH2BE acts as an important communication node, supporting the normal operation of auxiliary control loops and distributed monitoring systems.

Core Advantages and Technical Highlights

IONet Configuration Flexibility

Equipped with two IONet 10Base2 Ethernet ports (BNC connectors) and one RS-485 port (D-type), the GE IS215VCMIH2BE supports flexible network configurations for medium-scale control systems. The IONet ports can be configured for separate I/O rack communication or simple redundant paths, meeting the reliability requirements of non-critical control loops. The RS-485 port enables long-distance communication (up to 1200 meters) with field devices such as remote pressure sensors or valve controllers, expanding the module’s application scope. The IONet protocol’s low-latency feature ensures timely transmission of control commands, while the RS-485 port’s differential signaling resists noise in long-cable runs—ideal for turbine auxiliary systems with distributed equipment.

Balanced Environmental Adaptability

With an operating temperature range of -35°C to +65°C, the GE IS215VCMIH2BE performs well in general industrial environments, including regions with slightly colder winters. Its circuit design adopts basic dust-proof measures, reducing the impact of common industrial dust on module performance. The expanded 64 KB Flash memory allows storing more control logic configurations, calibration data, or firmware versions, eliminating the need for external memory expansion in most medium-scale applications. The module’s basic electromagnetic compatibility (EMC) design can resist general electrical interference, ensuring stable data transmission in standard industrial electrical environments.

Practical Diagnostic Function

The GE IS215VCMIH2BF integrates essential LED indicators, including Status, Fail, Run, and IONet port activity lights (TX/RX/CD). These indicators provide clear real-time visual feedback on the module’s operational state, allowing maintenance personnel to quickly identify common issues. For example, an unlit port TX/RX light can signal a loose IONet cable connection, and a solid “Fail” LED may indicate a power supply problem. This practical diagnostic function simplifies daily maintenance work, reduces the difficulty of troubleshooting, and helps shorten system downtime in case of minor faults.

Typical Application Scenarios

Turbine Auxiliary Control Systems

In turbine auxiliary control systems of thermal power plants, the GE IS215VCMIH2BE serves as a key communication module. It connects to GE IS220UCSAH1A analog input modules via IONet, collecting data on lubricating oil pressure and cooling water temperature, while using the RS-485 port to communicate with remote pump status sensors located in the plant’s auxiliary equipment area (up to 800 meters away). This data is transmitted to the Mark VI auxiliary controller, which adjusts oil pumps and cooling fans. The module’s -35°C lower temperature limit ensures reliable startup in cold winter conditions, while the RS-485 port simplifies wiring for distributed auxiliary equipment.

Wastewater Treatment Plant Monitoring Systems

In medium-scale wastewater treatment plants, the GE IS215VCMIH2BE facilitates data exchange between distributed I/O racks and the central control system. It uses IONet to connect to GE IS220UCSAH1A analog input modules for collecting water quality parameters (pH, dissolved oxygen) from treatment tanks, and the RS-485 port to communicate with remote sludge level sensors in sedimentation basins (over 1000 meters away). The module relays this data to the central SCADA system, enabling operators to monitor the treatment process in real time. Its cost-effective design meets the budget of municipal wastewater facilities, while the RS-485 port reduces wiring costs compared to Ethernet for long-distance connections.

GE IS215VCMIH2BF

Related Model Recommendations

GE IS215VCMIH2B: The base model of the GE IS215VCMIH2BE with RS-232C instead of RS-485, suitable for systems without long-distance communication needs.

GE IS215VCMIH2BF: A variant with 32 KB Flash and RS-232C, ideal for cost-sensitive applications with basic communication requirements.

GE IS215VCMIH2C: An upgraded model with 3 IONet ports and 128 KB Flash, designed for large-scale turbine control systems.

GE IS215VCMIH2CC: A high-end model with conformal coating and extended temperature range, tailored for ultra-harsh offshore environments.

GE IS220UCSAH1A: Analog input module that pairs with the GE IS215VCMIH2BE to collect temperature, pressure, and water quality data.

GE IS220YDIAS1A: Digital input module that works with the GE IS215VCMIH2BE to monitor equipment running status and switch signals.

GE IS220PCAAH1A: VME bus power supply module that provides stable +5V DC power to the GE IS215VCMIH2BE and other chassis components.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the GE IS215VCMIH2BE, power off the Mark VI VME chassis and ensure the workspace is equipped with ESD protection (grounded mats and wristbands). Required tools include a Phillips screwdriver, BNC cable tester, RS-485 cable tester, and torque wrench (set to 0.5 N·m). Verify the chassis slot conforms to 6U VME standards, then align the module’s edge connectors with the slot guides—avoid applying excessive force to prevent pin damage. Secure the module with front-panel screws, connect shielded BNC cables for IONet (max length 185 meters), and use twisted-pair shielded cables for RS-485 (max length 1200 meters). Configure network parameters via GE’s Proficy Machine Edition software before powering on.

Maintenance Suggestions

Conduct monthly inspections of the GE IS215VCMIH2BE to check LED statuses and cable connections, focusing on BNC and RS-485 connectors for corrosion or looseness. Clean the module’s ventilation slots quarterly using compressed air (pressure ≤0.5MPa). For RS-485 issues (e.g., communication dropouts), test cable continuity and check for ground loops. If a fault is detected, use LED indicators to isolate problems—e.g., a blinking “Fail” LED may signal memory errors. For firmware updates, use GE-authorized software. Replace with genuine GE spares (lead time 3-5 days) and restore configuration backups to minimize downtime.

Service and Guarantee Commitment

The GE IS215VCMIH2BE comes with a 12-month manufacturer’s warranty covering defects in materials and workmanship. GE’s global technical support team provides 24/7 assistance via email and online portals, offering guidance on installation, RS-485 network configuration, and troubleshooting. For critical applications, certified GE engineers can be dispatched to customer sites within 48 hours in major industrial regions.

Extended warranty plans up to 3 years are available, including preventive maintenance checks to optimize module performance. GE also offers customized training on RS-485 network design and Mark VI integration to help customers maximize the GE IS215VCMIH2BE’s value. With decades of industrial automation expertise, GE stands behind the module’s reliability and supports customers throughout its lifecycle.