Description

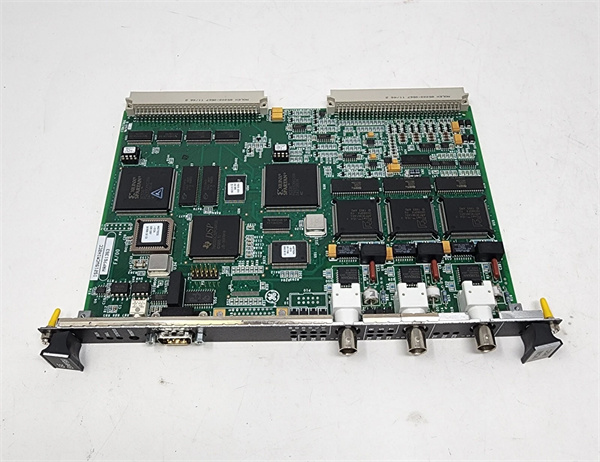

GE IS215VCMIH2CB Product Description

Detailed parameter table

| Parameter Name | Parameter Value |

| Product model | GE IS215VCMIH2CB |

| Manufacturer | General Electric (GE) |

| Product category | VME Bus Master Controller/Communication Interface Module |

| Series | Mark VI Speedtronic |

| Processor | Texas Instruments TMS320C32 32-bit DSP |

| Memory | 32 KB Dual-Port SRAM |

| Communication ports | 3x IONet 10Base2 Ethernet (BNC), 1x RS-232C (D-type) |

| Operating temperature range | -20°C to +60°C |

| Power supply | +5V DC (VME bus standard) |

| Installation method | Mark VI standard VME chassis 6U slot mounting |

| Safety certifications | CE, UL 508 |

| Physical size | 10.16 cm (W) × 22.86 cm (H) × 12.7 cm (D) |

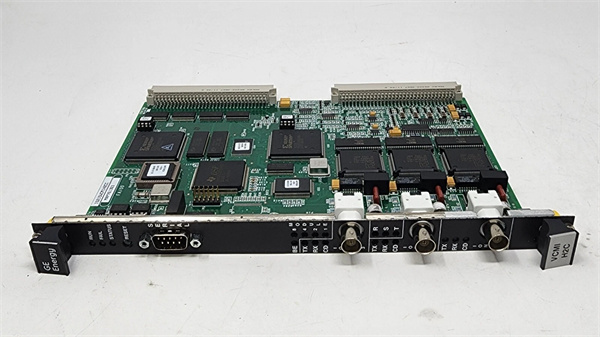

GE IS215VCMIH2CC

Product introduction

The GE IS215VCMIH2CB is a critical VME bus master controller and communication interface module under GE’s Mark VI Speedtronic series, specifically developed for turbine control and industrial automation systems. As the central data exchange hub in Mark VI-based setups, it manages the flow of commands and real-time data between distributed controllers, I/O modules, and the proprietary IONet system control network, ensuring seamless integration and coordinated operation of the entire control ecosystem.

Designed with precision and reliability in mind, the GE IS215VCMIH2CB leverages a 32-bit Texas Instruments TMS320C32 DSP to handle complex mathematical computations and signal processing tasks essential for turbine control. Its dual-port SRAM enables simultaneous data access from multiple system components, reducing latency and enhancing response speed. In automation systems, this module acts as the “nervous system,” facilitating deterministic communication that is vital for maintaining stable performance in applications like gas turbine speed regulation and process parameter monitoring.

Core advantages and technical highlights

IONet Communication Efficiency: The GE IS215VCMIH2CB is equipped with three IONet 10Base2 Ethernet ports (BNC connectors) that support GE’s proprietary IONet protocol. This protocol is optimized for low-latency, high-reliability data transmission, making the module ideal for time-sensitive turbine control tasks. Each IONet port is paired with TX/RX/CD LED indicators, providing real-time visibility into network activity and enabling quick identification of communication anomalies, which minimizes troubleshooting time and system downtime.

Intuitive Diagnostic Capabilities: The GE IS215VCMIH2CB features a comprehensive set of LED indicators, including Status, Fail, Run, and numbered port indicators. These visual cues allow operators to instantly assess the module’s operational state—from normal running conditions to fault scenarios—without requiring complex diagnostic tools. For example, a lit Fail LED combined with specific port indicators can quickly pinpoint issues like IONet cable disconnections or power supply irregularities, streamlining maintenance workflows.

VME Bus Optimization: As a dedicated VME bus master controller, the GE IS215VCMIH2CB efficiently manages bus arbitration and data prioritization. This ensures that critical control commands receive precedence over non-essential data, preventing bus congestion and maintaining system responsiveness. The module’s compliance with 6U VME standards also guarantees seamless compatibility with other Mark VI series components, simplifying system integration and upgrade processes.

Typical application scenarios

In onshore gas turbine power plants, the GE IS215VCMIH2CB plays a pivotal role in turbine speed and load control. It collects real-time data from vibration sensors (such as GE IS220PVIBH1A) and temperature transmitters, then transmits this information via IONet to the Mark VI main controller. The controller uses this data to adjust fuel flow and air intake, optimizing combustion efficiency and preventing turbine overspeed. The module’s -20°C to +60°C operating temperature range makes it well-suited for the moderate environmental conditions of onshore power facilities.

In petrochemical refineries, the GE IS215VCMIH2CB facilitates process automation in catalytic cracking units. It connects to distributed I/O modules like GE IS220UCSAH1A to monitor reactor pressure and catalyst temperature, relaying these parameters to the SCADA system. During peak production periods, the module’s efficient VME bus management ensures that control commands—such as adjusting valve positions to maintain pressure—are executed without delay, reducing the risk of process deviations and improving product quality consistency.

Related model recommendations

GE IS215VCMIH2C: An upgraded version of the GE IS215VCMIH2CB with enhanced firmware for improved compatibility with newer Mark VI components and extended operating temperature range.

GE IS215VCMIH2CC: A sibling model with conformal coating for enhanced protection against moisture and corrosion, suitable for harsh offshore environments.

GE IS220UCSAH1A: Analog input module that pairs with the GE IS215VCMIH2CB to acquire temperature, pressure, and flow data from field sensors.

GE IS220PVIBH1A: Vibration monitoring module that works with the GE IS215VCMIH2CB to detect turbine imbalance and bearing wear.

GE IS220PCAAH1A: VME bus power supply module that provides stable +5V DC power to the GE IS215VCMIH2CB and other chassis components.

GE IS215VPROH1B: Communication processing module that complements the GE IS215VCMIH2CB by adding Modbus TCP support for integration with third-party systems.

GE IS215VCMIH2CC

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the GE IS215VCMIH2CB, power off the Mark VI VME chassis and ensure the working area is free from dust and electrostatic discharge (ESD). Required tools include a Phillips screwdriver, ESD wristband, and BNC cable tester. Verify that the chassis slot conforms to 6U VME standards, then align the module’s edge connectors with the slot guides. Insert the module firmly until it seats completely, and secure it with front-panel screws. Use shielded BNC cables for IONet connections, keeping cable lengths under 185 meters to maintain signal integrity, and connect the RS-232C port for initial configuration via GE’s Proficy Machine Edition software.

Maintenance suggestions: Perform monthly inspections of the GE IS215VCMIH2CB to check LED statuses and cable connections. Clean the module’s ventilation openings quarterly using compressed air (pressure ≤0.5MPa) to prevent dust accumulation. If a fault occurs, first verify IONet cable continuity and power supply stability. For firmware updates, use GE’s authorized software tools to ensure compatibility. When replacing the module, use only genuine GE spare parts and reconfigure network parameters to match the original setup. Regularly back up configuration data to minimize downtime during maintenance.

Service and guarantee commitment

The GE IS215VCMIH2CB is backed by a 12-month manufacturer’s warranty covering defects in materials and workmanship. GE’s global technical support team offers 24/7 assistance via email and online portals, providing expert guidance on installation, configuration, and troubleshooting. For critical applications, certified GE engineers can be dispatched to customer sites within 48 hours of a service request in major industrial regions.

Extended warranty plans up to 3 years are available, offering additional coverage for long-term operational peace of mind. GE also provides customized training programs to help customers maximize the performance of the GE IS215VCMIH2CB and integrate it effectively into their automation systems. With decades of experience in industrial control, GE stands behind the reliability of the GE IS215VCMIH2CB and is committed to supporting customers throughout the product’s lifecycle.