Description

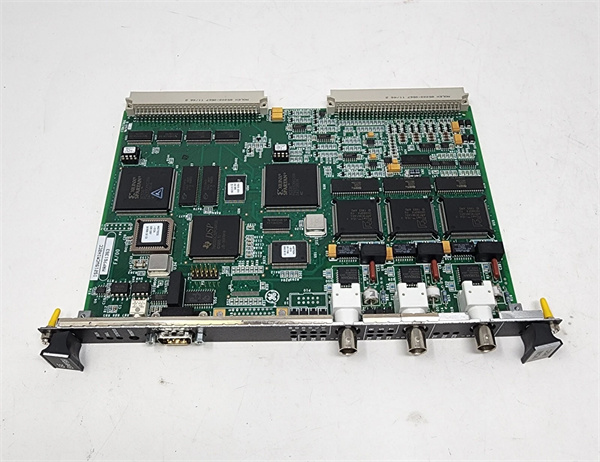

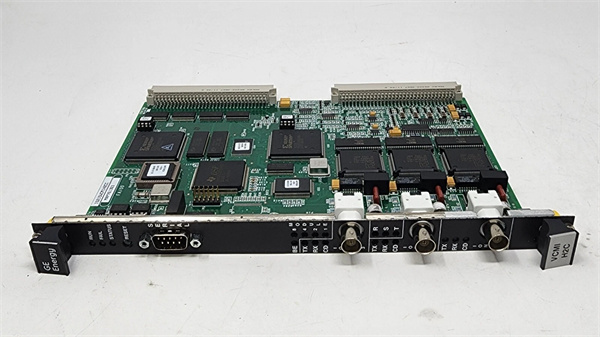

GE IS215VCMIH2CC Product Description

Detailed parameter table

| Parameter Name | Parameter Value |

| Product model | GE IS215VCMIH2CC |

| Manufacturer | General Electric (GE) |

| Product category | VME Bus Master Controller/Communication Interface Module |

| Series | Mark VI Speedtronic |

| Processor | Texas Instruments TMS320C32 32-bit DSP |

| Memory | 32 KB Dual-Port SRAM + 128 KB Flash |

| Communication ports | 3x IONet 10Base2 Ethernet (BNC), 1x RS-232 (D-type) |

| Operating temperature range | -40°C to +85°C |

| Power supply | +5V DC (VME bus standard) |

| Installation method | Mark VI standard VME chassis slot mounting |

| Safety certifications | CE, UL 508 |

| Physical size | 10.16 cm (W) × 22.86 cm (H) × 12.7 cm (D) |

GE IS215VCMIH2CC

Product introduction

The GE IS215VCMIH2CC is a high-performance VME bus master controller and communication interface module belonging to GE’s renowned Mark VI Speedtronic series, specifically engineered for mission-critical industrial control systems. As the central communication hub of Mark VI-based setups, it serves as the backbone for data exchange between controllers, distributed I/O modules, and the proprietary IONet system control network, ensuring seamless integration of field devices and supervisory platforms.

Designed with turbine control and process automation in mind, the GE IS215VCMIH2CC combines robust processing capabilities with specialized communication features. Its 32-bit DSP processor enables real-time data processing, while the dual-port SRAM and Flash memory ensure reliable storage and quick access to critical control data. In automation systems, this module plays a pivotal role in maintaining deterministic communication, which is essential for applications requiring precise timing and consistent performance, such as gas and steam turbine control.

Core advantages and technical highlights

IONet Protocol Optimization: The GE IS215VCMIH2CC is equipped with three IONet 10Base2 Ethernet ports (BNC connectors), leveraging GE’s proprietary IONet protocol optimized for low-latency, high-reliability communication in turbine control systems. This dedicated network support ensures deterministic data transmission, a critical requirement for monitoring and adjusting parameters like rotor speed, vibration, and fuel flow in real time, minimizing response delays even in complex industrial environments.

Robust Industrial Durability: Built to withstand extreme operating conditions, the GE IS215VCMIH2CC features a wide operating temperature range of -40°C to +85°C and conformal coating on circuit boards. This protection shields the module from dust, moisture, and chemical corrosion, making it ideal for harsh settings such as power plant turbine halls and petrochemical refineries. Additionally, front-panel LED indicators for status, fail, run, and network activity provide intuitive real-time diagnostics, simplifying troubleshooting.

Redundancy and Fault Tolerance: The GE IS215VCMIH2CC supports triple modular redundancy (TMR) systems, a key advantage for critical applications where downtime is unacceptable. By enabling redundant data paths and processing, the module ensures continuous operation even if individual components fail. This fault-tolerant design, combined with hot-swapping capability (allowing maintenance without system shutdown), significantly enhances the availability and reliability of the entire Mark VI control system.

Typical application scenarios

In power generation, the GE IS215VCMIH2CC is a cornerstone of gas and steam turbine control systems. It manages data flow between Mark VI controllers, vibration monitoring modules (such as GE IS220PVIBH1A), and temperature sensors, ensuring operators receive real-time insights into turbine performance. For example, in a combined-cycle power plant, the module transmits rotor speed and exhaust gas temperature data via IONet, enabling the controller to adjust fuel injection and cooling systems dynamically, optimizing efficiency and preventing equipment overheating.

In the oil and gas industry, the GE IS215VCMIH2CC facilitates process automation in refineries and pipeline operations. It integrates with distributed I/O modules to collect data from pressure transmitters and valve position sensors, then relays this information to SCADA systems. During crude oil distillation, the module ensures precise communication between the control system and actuators, maintaining stable pressure and temperature levels in distillation columns. Its rugged design also withstands the high-vibration, corrosive environment common in offshore drilling platforms, ensuring uninterrupted operation.

Related model recommendations

GE IS215VCMIH2B: An earlier version of the GE IS215VCMIH2CC with 1x IONet port and lower processing capacity, suitable for smaller-scale turbine control systems.

GE IS220UCSAH1A: A Mark VI analog input module that pairs with the GE IS215VCMIH2CC to acquire temperature, pressure, and flow data from field sensors for transmission to the control system.

GE IS220PVIBH1A: A vibration input module that works with the GE IS215VCMIH2CC to monitor turbine vibration parameters, enhancing predictive maintenance capabilities.

GE IS215VPROH2B: A Mark VI communication processing module that complements the GE IS215VCMIH2CC by supporting additional industrial protocols like Modbus TCP for integration with third-party systems.

GE IS220PCAAH1A: A Mark VI power supply module that provides stable +5V DC power to the GE IS215VCMIH2CC and other VME bus modules in the control chassis.

GE IS215VCMIH2C: A revised version of the GE IS215VCMIH2CC with updated firmware for enhanced compatibility with newer Mark VI system components.

GE IS215VCMIH2CC

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the GE IS215VCMIH2CC, ensure the Mark VI VME chassis is powered off and the working environment is clean, dry, and free from corrosive gases. Required tools include a Phillips screwdriver, ESD wristband (to prevent electrostatic damage), and BNC cable crimping tool. Verify the chassis slot is compatible with VME bus standards, then align the module with the slot guides, insert firmly until it seats correctly, and fasten the front-panel screws. Use shielded BNC cables for IONet connections, ensuring cable lengths do not exceed 185 meters (10Base2 maximum), and connect the RS-232 port for initial configuration if needed.

Maintenance suggestions: Conduct monthly visual inspections of the GE IS215VCMIH2CC to check LED status indicators and secure cable connections. Clean the module’s ventilation slots and chassis slot quarterly using compressed air (max pressure 0.5MPa) to remove dust buildup. If a fault is detected, first check IONet cables and connectors for damage, then use GE’s Proficy Machine Edition software to access diagnostic logs. When replacing the module, use genuine GE spares to ensure compatibility and maintain system reliability, and reconfigure network parameters to match the original setup before restoring operation.

Service and guarantee commitment

The GE IS215VCMIH2CC comes with a 12-month manufacturer’s warranty covering defects in materials and workmanship. GE’s global technical support team provides 24/7 assistance via email, online portals, and phone, offering expert guidance on installation, configuration, and troubleshooting. For on-site service needs, certified GE engineers can be dispatched to customer locations within 48 hours in major industrial regions, ensuring minimal downtime for critical systems.

Extended warranty plans up to 3 years are available, providing additional peace of mind for long-term operational stability. GE also offers customized training programs to help customers maximize the performance of the GE IS215VCMIH2CC and integrate it seamlessly into their automation ecosystems. With a legacy of reliability in industrial control, GE stands behind the quality of the GE IS215VCMIH2CC and is committed to supporting customers throughout the product’s lifecycle.