Description

IS215WETAH1BA: Product Overview

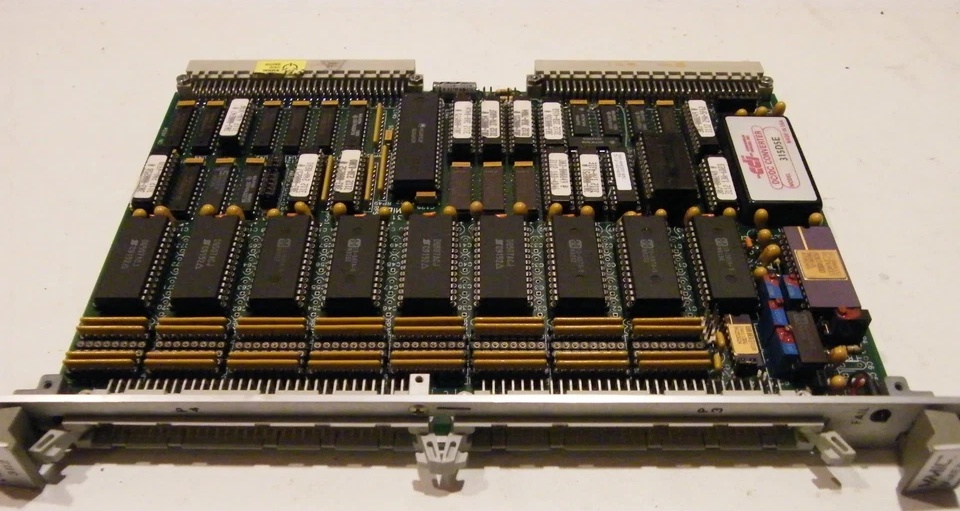

The GE IS215WETAH1BA is a wind turbine control module developed for GE Mark VIe wind turbine control systems, a legacy platform renowned for its reliability in industrial power generation. As part of the Mark VIe ecosystem, it acts as a “field signal gateway,” connecting analog/digital sensors (e.g., temperature, pressure, vibration) to the VMEbus-based control system. Its primary role is to ensure accurate signal transmission and real-time monitoring, which are critical for maintaining turbine efficiency and safety.

Role in Automation Systems:

Positioned as a “field signal interface” in Mark VIe architectures, the IS215WETAH1BA performs two primary functions:

-

Signal Acquisition: Receives analog signals from field devices (e.g., a thermocouple measuring turbine exhaust temperature) and converts them into digital data via a 16-bit ADC (Analog-to-Digital Converter).

-

Signal Transmission: Sends processed data to the VMEbus controller (e.g., GE Fanuc 90-30 series) for real-time analysis (e.g., adjusting fuel flow to maintain optimal efficiency) and receives control commands to drive actuators (e.g., solenoid valves).

Core Functionality:

-

VMEbus Compatibility: Conforms to VMEbus Rev. C.1, ensuring seamless integration with VME64 backplanes and controllers. This allows the module to work with existing Mark VIe components without major system upgrades.

-

Flexible Signal Handling: Supports multiple analog signal types (0–5V DC, 0–10V DC, 4–20 mA) through configurable input channels, making it adaptable to diverse field devices.

-

High Precision: The 16-bit ADC ensures accurate signal conversion (error < ±0.1% full-scale), critical for maintaining turbine stability.

-

Rugged Design: Industrial-grade components and a compact 6U Eurocard form factor enable 24/7 operation in high-temperature, high-vibration environments (e.g., wind turbine nacelles).

Platform Benefits (Mark VIe Series):

The IS215WETAH1BA inherits the Mark VIe platform’s strengths, including:

-

Reliability: The Mark VIe system is the industry standard for wind turbine control, with a proven track record of 24/7 operation in wind farms worldwide.

-

Legacy Compatibility: The module is designed to work with existing Mark VIe components (e.g., I/O modules, contactors), reducing the cost of system upgrades.

-

Scalability: Supports expansion with additional analog input boards or I/O modules to accommodate growing system demands (e.g., adding more sensors to a turbine).

DS2000CPCAG1A

Technical Specifications

-

Model Number: IS215WETAH1BA (Variant of Mark VIe Series)

-

Manufacturer: GE (General Electric)

-

Product Type: Wind Turbine Control Module

-

Series: Mark VIe (Wind Turbine Control)

-

Form Factor: 6U Eurocard (160 mm × 233 mm)

-

Bus Standard: VMEbus Rev. C.1 (supports 8/16/32-bit data transfer)

-

Input Channels: 8 (configurable for voltage/current signals)

-

Input Signal Ranges: 0–5V DC, 0–10V DC, 4–20 mA (programmable via jumpers)

-

Resolution: 16-bit (analog-to-digital conversion)

-

Sampling Rate: Up to 1000 Hz per channel (real-time processing)

-

Isolation: Galvanic isolation (optocouplers, 1500 V AC channel-to-channel)

-

Accuracy: ±0.1% full-scale (at 25°C)

-

Operating Temperature: 0°C to +55°C (32°F to 131°F)

-

Storage Temperature: -40°C to +85°C (-40°F to 185°F)

-

Humidity: 5–95% non-condensing

-

Weight: 0.2 kg (0.44 lbs)

-

Certifications: CE, UL (inferred from GE industrial product standards)

Core Features & Customer Value

1. Reliable Signal Acquisition:

The IS215WETAH1BA’s galvanic isolation and high-precision ADC ensure accurate signal conversion, even in electrically noisy environments. For example, in a wind farm, the module can reliably measure turbine blade vibration (via a piezoelectric sensor) and transmit the data to the VMEbus controller, which triggers a warning if the vibration exceeds a threshold.

2. Flexible Configuration:

Configurable input channels allow engineers to customize the module’s functionality for different field devices, reducing the need for additional signal conditioning hardware. This flexibility saves time and money during installation.

3. Rugged Industrial Design:

The module’s operating temperature range (0°C to +55°C) and compact form factor make it suitable for harsh industrial environments. Its DIN rail mounting option simplifies installation in crowded control cabinets, reducing setup time and effort.

4. Easy Integration:

VMEbus compatibility ensures seamless integration with existing VMEbus systems, minimizing downtime and effort during upgrades. This is invaluable for facilities with legacy VMEbus installations, allowing them to enhance system capabilities without replacing entire architectures.

Typical Applications

The GE IS215WETAH1BA is widely used in industrial automation systems for:

-

Wind Power Generation:

-

Monitors analog signals from wind turbines (e.g., blade position, fuel flow, temperature) for real-time control, ensuring stable power output.

-

-

Manufacturing:

-

Used in assembly lines to acquire analog signals from sensors (e.g., pressure, flow) and control actuators (e.g., valves, motors).

-

-

Petrochemical Industry:

-

Acquires analog signals from refinery equipment (e.g., distillation columns, pumps), ensuring safe and efficient operation in hazardous environments.

-