Description

Product Overview

The GE IS220PPDAH1B is a remarkable power distribution feedback module, an integral part of GE’s esteemed Mark VIe turbine control system series. It is specifically designed to play a pivotal role in industrial automation, especially in turbine control scenarios. This module is responsible for handling crucial tasks such as conditioning feedback signals from circuit boards and providing Ethernet interfaces for connected controllers. By automatically identifying and determining the power requirements of the connected power distribution model through its electronic ID, it enables a seamless “plug – and – play” functionality. In the context of the overall automation system, the IS220PPDAH1B ensures accurate data transfer and control, contributing significantly to the stable and efficient operation of the system, whether it’s in a power generation plant or an industrial manufacturing facility.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS220PPDAH1B |

| Manufacturer | GE |

| Product Type | Power Distribution Feedback Module |

| Output Voltage | 28 VDC |

| Self – diagnostic Tests | 5 types |

| Installation Location | Can be installed on JPDS, JPDC or JPDM boards |

| Diagnostic Signals | Two 115/230VAC analog feedback, local ground signal, six fused AC signals, etc. |

| Dimensions | Approximately 190.5mm (L) × 139.7mm (W) × 38.1mm (H) |

| Weight | Approximately 0.68kg |

| Manual | GEH – 6721 Mark VIe Control Volume II System Hardware Guide |

IS220PDIAH1BE 336A5026ADP4

Main Features and Advantages

Plug – and – Play Functionality: The IS220PPDAH1B simplifies installation with its automatic power requirement identification. This not only reduces setup time but also minimizes the chance of human – error during configuration, making it accessible for technicians with varying levels of expertise.

Signal Conditioning: It excels at precisely conditioning feedback signals from boards like JPDB, JPDF, and JPDE. This ensures that the data sent to the Mark VIe control system is accurate, enabling the system to make well – informed decisions and maintain optimal control over the process.

Ethernet Connectivity: Equipped with two Ethernet ports, the module can integrate multiple communication protocols such as Modbus TCP/IP, Ethernet/IP, and Profinet. This broad compatibility allows it to communicate effectively with a wide range of devices, facilitating the creation of complex and interconnected industrial networks.

Automatic Reconfiguration: In case of module replacement, the IS220PPDAH1B can reconfigure itself without manual intervention. This feature significantly reduces system downtime, which is crucial for industries where continuous operation is essential, ultimately saving costs and enhancing productivity.

Compact Design: Its small size and light weight make it easy to install in spaces with limited room, optimizing system layout and reducing the complexity of installation.

Signal Conditioning: It excels at precisely conditioning feedback signals from boards like JPDB, JPDF, and JPDE. This ensures that the data sent to the Mark VIe control system is accurate, enabling the system to make well – informed decisions and maintain optimal control over the process.

Ethernet Connectivity: Equipped with two Ethernet ports, the module can integrate multiple communication protocols such as Modbus TCP/IP, Ethernet/IP, and Profinet. This broad compatibility allows it to communicate effectively with a wide range of devices, facilitating the creation of complex and interconnected industrial networks.

Automatic Reconfiguration: In case of module replacement, the IS220PPDAH1B can reconfigure itself without manual intervention. This feature significantly reduces system downtime, which is crucial for industries where continuous operation is essential, ultimately saving costs and enhancing productivity.

Compact Design: Its small size and light weight make it easy to install in spaces with limited room, optimizing system layout and reducing the complexity of installation.

Application Field

Gas Turbine Systems: In gas turbine power generation, the IS220PPDAH1B is vital for monitoring and controlling the power distribution system. It ensures the gas turbine operates efficiently by providing real – time feedback and enabling precise control, leading to increased power generation efficiency and reduced operational costs.

Steam Turbine Systems: Similar to its role in gas turbines, it is essential for the power distribution management in steam turbine generators. By maintaining stable power distribution, it guarantees the reliable operation of the steam turbine system, which is crucial for meeting the power demands of industries and communities.

Power Plant Auxiliary Systems (BOP) Control: The module actively participates in the overall control and monitoring of power plant auxiliary systems. By effectively managing power distribution, it enhances the operational efficiency and stability of these auxiliary systems, which in turn supports the smooth operation of the entire power plant.

Steam Turbine Systems: Similar to its role in gas turbines, it is essential for the power distribution management in steam turbine generators. By maintaining stable power distribution, it guarantees the reliable operation of the steam turbine system, which is crucial for meeting the power demands of industries and communities.

Power Plant Auxiliary Systems (BOP) Control: The module actively participates in the overall control and monitoring of power plant auxiliary systems. By effectively managing power distribution, it enhances the operational efficiency and stability of these auxiliary systems, which in turn supports the smooth operation of the entire power plant.

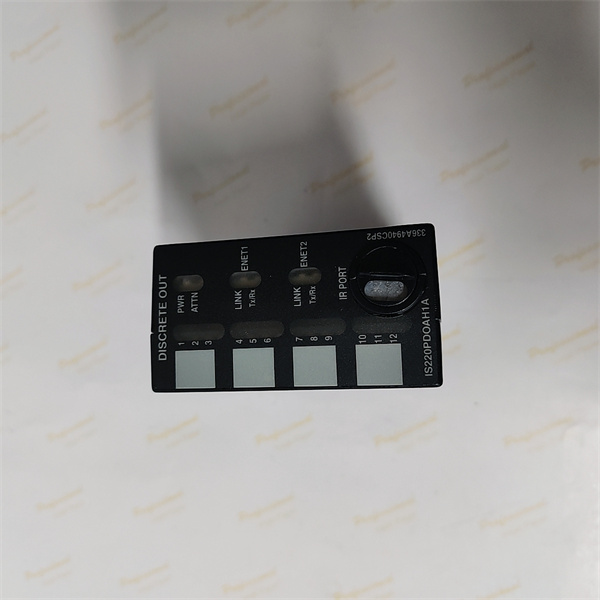

IS220PDOAH1A 336A4940CSP2

Related Products

IS220PPDAH1: An earlier version of the module. It shares basic functionality with IS220PPDAH1B, but may lack some of the advanced features or improvements in the latter, such as enhanced signal processing or more efficient communication capabilities.

JPDB, JPDF, JPDE Boards: These boards work in tandem with the IS220PPDAH1B by providing the feedback signals it processes. Each board has its own specific functions within the power distribution system, and together with the IS220PPDAH1B, they ensure comprehensive power distribution monitoring.

JPDC, JPDS, JPDM, JPDG Power Boards: They are compatible with the IS220PPDAH1B. The module can be installed on JPDM, JPDC, or JPDS boards and can be connected to more of these power boards via a fifty – pin ribbon cable jumper. They are involved in different aspects of power distribution, and their collaboration with the IS220PPDAH1B forms a complete power distribution feedback system.

JPDB, JPDF, JPDE Boards: These boards work in tandem with the IS220PPDAH1B by providing the feedback signals it processes. Each board has its own specific functions within the power distribution system, and together with the IS220PPDAH1B, they ensure comprehensive power distribution monitoring.

JPDC, JPDS, JPDM, JPDG Power Boards: They are compatible with the IS220PPDAH1B. The module can be installed on JPDM, JPDC, or JPDS boards and can be connected to more of these power boards via a fifty – pin ribbon cable jumper. They are involved in different aspects of power distribution, and their collaboration with the IS220PPDAH1B forms a complete power distribution feedback system.

Installation and Maintenance

Pre – installation preparation: Before installing the IS220PPDAH1B, carefully read the product installation manual. Ensure that the installation environment meets the module’s requirements in terms of temperature, humidity, and electromagnetic interference. Prepare necessary tools and wear anti – static equipment to prevent electrostatic damage. Check the integrity of the module and all related components.

Maintenance recommendations: Regularly inspect the IS220PPDAH1B for any signs of physical damage or overheating. Utilize its self – diagnostic functions and diagnostic signals to monitor its operational status. In case of a malfunction, refer to the product manual for troubleshooting steps. If needed, contact GE’s professional technical support. Keep the module clean to ensure proper heat dissipation and stable operation.

Maintenance recommendations: Regularly inspect the IS220PPDAH1B for any signs of physical damage or overheating. Utilize its self – diagnostic functions and diagnostic signals to monitor its operational status. In case of a malfunction, refer to the product manual for troubleshooting steps. If needed, contact GE’s professional technical support. Keep the module clean to ensure proper heat dissipation and stable operation.

Product Guarantee

GE offers a comprehensive product guarantee for the IS220PPDAH1B. The product comes with a quality assurance period, during which any defects in materials or workmanship will be rectified by GE free of charge. Their professional technical support team is always available to assist customers with installation guidance, operation advice, and troubleshooting. GE’s commitment to quality and customer satisfaction ensures that the IS220PPDAH1B can be relied upon for long – term, stable operation in industrial automation applications, giving customers peace of mind and confidence in their investment.