Description

GE IS220PTURH1A

Detailed parameter table

| Parameter name | Parameter value |

| Product model | IS220PTURH1A |

| Manufacturer | GE (General Electric) |

| Product category | Primary Turbine Trip Pack for Mark VIe control systems |

| Input voltage | 24 VDC |

| Output voltage | 24 VDC |

| Current | 5 A |

| Communication interfaces | Dual 100Mbps full – duplex Ethernet ports |

| I/O types | 4 passive magnetic speed inputs, supports analog, digital, and serial I/O via expansion |

| Connector type | DC – 62 pin connector for output |

| Memory | Flash memory and RAM for data storage |

| Operating temperature | – 40°C to + 85°C |

| Storage temperature | – 55°C to + 90°C |

| Humidity tolerance | 5% – 95% relative humidity, non – condensing |

| Vibration tolerance | 0.03 g rms, 5 Hz to 500 Hz |

| Shock tolerance | 15 g, 20 ms half – sine |

| Configuration options | Auto – reconfiguration through ToolboxST’s component editor, manual reconfiguration possible |

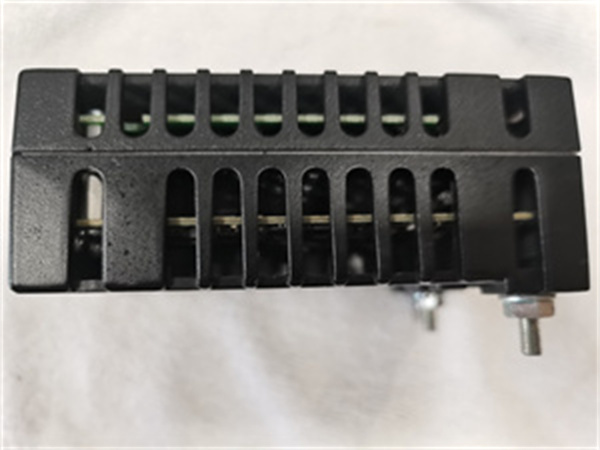

| Physical dimensions | 263 mm x 58 mm x 28 mm (length x width x height) |

| Mounting | Mounts to the TTURH1C terminal board |

| Weight | Approximately 650 g |

| Certification | Complies with relevant industrial standards for power generation and industrial applications |

GE IS220PTURH1A

Product introduction

The GE IS220PTURH1A is a crucial component within the GE Speedtronic Mark VIe gas turbine control system. As a primary turbine trip pack, it serves as a vital link in ensuring the safe and efficient operation of turbines across various power generation and industrial applications. Its main function is to establish an electrical interface between the turbine control terminal board and one or two Ethernet networks, enabling seamless data transfer and control signals flow.

This module plays a central role in digitizing sensor signals from the turbine, which are then fed to the controller. By providing electrical isolation between the turbine sensors and the controller, it safeguards the integrity of the control system, protecting it from potential electrical interferences that could otherwise disrupt turbine operation. Whether in a gas turbine power plant or an industrial steam turbine setup, the IS220PTURH1A is designed to withstand the harsh environmental conditions typical of such settings, making it a reliable choice for mission – critical applications.

Core advantages and technical highlights

Electrical isolation and signal digitization: The IS220PTURH1A excels in providing electrical isolation, which is essential for protecting the sensitive control system components from electrical noise and surges that can originate from the turbine’s high – voltage and high – current operations. Simultaneously, it digitizes sensor signals, converting them into a format that can be easily processed by the controller. This digitization process improves the accuracy and speed of data transmission, enabling the control system to make more precise decisions regarding turbine operation.

Redundant Ethernet connectivity: With dual 100Mbps full – duplex Ethernet ports, the module offers redundant communication paths. In power generation facilities, this redundancy is invaluable as it ensures continuous data flow between the turbine control system and other components such as SCADA systems or operator workstations. If one network link fails due to a cable break, hardware malfunction, or network congestion, the second link automatically takes over, preventing any interruption in the monitoring and control of the turbine.

Speed detection and trip functions: Equipped with four passive magnetic speed inputs, the IS220PTURH1A can accurately detect the speed of the turbine. Its circuit sensitivity is remarkable, capable of detecting a turning gear speed as low as 2 rpm. This high – level sensitivity allows for precise determination of the turbine’s speed, which is crucial for both normal operation and safety – critical functions. The median speed signal generated by the module is used for two key purposes: speed control during normal operation to maintain optimal turbine performance, and as a primary overspeed trip signal. In the event of an overspeed condition, where the turbine’s speed exceeds safe limits, the module quickly sends a trip signal to the controller, triggering emergency shutdown procedures to prevent potential damage to the turbine.

Auto – reconfiguration and data storage: The module supports auto – reconfiguration, a feature that simplifies system maintenance and upgrades. Through GE’s ToolboxST software and its component editor, the IS220PTURH1A can automatically download baseload, boot load, firmware, and parameters from the controller. This ensures that the module is always up – to – date with the latest system requirements. Additionally, it has flash memory and RAM for data storage, which is useful for caching sensor data, storing configuration settings, and facilitating smooth operation during periods of network or controller unavailability.

Typical application scenarios

In gas turbine power plants, the IS220PTURH1A is at the heart of the control system. It processes speed data from the turbine’s rotation sensors, along with other sensor inputs such as temperature and pressure. Based on this data, it sends control signals to adjust fuel valves, ensuring that the gas turbine operates at the optimal speed and temperature for maximum efficiency and minimal emissions. In case of any abnormal conditions, such as an overspeed event or a sudden drop in pressure, it quickly triggers the appropriate safety mechanisms to protect the turbine.

Industrial steam turbines, commonly used in manufacturing plants for power generation and process heating, also rely on the IS220PTURH1A. The module monitors the steam turbine’s speed and other critical parameters, coordinating with the plant’s control system to meet the electrical and thermal demands of the manufacturing processes. For example, in a paper mill, the steam turbine may power the machinery while also providing steam for heating the pulp. The IS220PTURH1A ensures that the turbine operates smoothly, adjusting its speed and output as required by the changing demands of the production process.

Combined – cycle power plants, which combine the efficiency of gas turbines and steam turbines, benefit from the IS220PTURH1A in multiple ways. It plays a role in controlling both the gas and steam turbines, ensuring seamless integration between the two power – generating units. By accurately monitoring and controlling the speeds of the turbines, it helps optimize the overall power generation efficiency of the combined – cycle plant, reducing fuel consumption and increasing electricity output.

GE IS220PTURH1A

Related model recommendations

GE IS220PPROH1A: A turbine – specific I/O module designed for direct interfacing with turbine field devices. It is often used in aeroderivative turbine emergency trip applications and can be paired with the IS220PTURH1A to enhance the overall turbine protection and control system.

GE IS220PDOAH1A, REV D: A discrete output terminal board that can be integrated with the IS220PTURH1A in industrial automation setups. It offers versatile connectivity options with multiple connectors, including 3 SRly, 3 TRly, 1 DC, and 2 RJ45, and is compatible with six discrete output terminal boards, expanding the I/O capabilities of the overall system.

GE IS215UCCCM04A: A processor module for Mark VIe turbine control systems. When used in conjunction with the IS220PTURH1A, it can provide the computational power required to process the digitized sensor signals received from the IS220PTURH1A, enabling more complex control algorithms to be executed for better turbine performance.

GE TTURH1C Terminal Board: The IS220PTURH1A is designed to mount onto the TTURH1C terminal board. This board provides the necessary electrical connections and mechanical support for the IS220PTURH1A, ensuring a stable and reliable installation within the turbine control system.

GE ToolboxST Software: This software is essential for configuring and maintaining the IS220PTURH1A. It allows for auto – reconfiguration of the module, as well as monitoring and troubleshooting its performance. Updating the ToolboxST software ensures that the IS220PTURH1A is compatible with the latest system requirements and has access to the most recent features and bug fixes.

Installation, commissioning and maintenance instructions

Installation preparation: Before installation, ensure that the power to the Mark VIe control system is switched off to prevent any electrical accidents. Inspect the TTURH1C terminal board where the IS220PTURH1A will be mounted for any signs of damage or debris. Use anti – static gloves and proper ESD (Electro – Static Discharge) safety precautions when handling the module, as it is sensitive to electrostatic charges. Verify that the 24 VDC power supply is stable and properly fused to avoid voltage spikes during startup.

Commissioning steps: After physically installing the IS220PTURH1A onto the TTURH1C terminal board, power on the Mark VIe control system. Use GE’s ToolboxST software to configure the module. Set up the network settings for the Ethernet ports, including IP addresses and subnet masks. Conduct functional tests by simulating turbine speed inputs using a signal generator and verifying that the module correctly digitizes and transmits the signals to the controller. Check the redundancy of the Ethernet ports by disconnecting one cable at a time and ensuring that data transfer continues uninterrupted through the remaining port. Also, test the speed detection and trip functions by simulating overspeed conditions and verifying that the module sends the appropriate trip signals to the controller.

Maintenance suggestions: Regularly perform visual inspections of the IS220PTURH1A and its connections. Check for any loose wires, signs of overheating, or damage to the module’s casing. Clean the module using compressed air to remove dust and debris, especially from the air circulation openings. Monitor the module’s performance through the ToolboxST software, paying attention to parameters such as data transfer rates, speed detection accuracy, and power consumption. If the module’s performance degrades or error messages are displayed, refer to the diagnostic LED indicators on the module (which show network status, power, and attention) and consult the GE – provided manuals or datasheets for troubleshooting steps. Schedule regular firmware updates using the ToolboxST software to ensure that the module has the latest bug fixes and performance enhancements. In case of a malfunction, consider sending the module to an authorized GE service center or a qualified repair facility with experience in handling GE turbine control components.

Service and guarantee commitment

GE offers a 12 – month factory warranty for the IS220PTURH1A, covering manufacturing defects and performance issues that occur under normal operating conditions. Their global technical support team is available 24/7 to provide assistance. For customers facing issues with the module, GE can offer remote diagnostics via secure connections, helping to quickly identify and resolve problems, thereby minimizing downtime. In critical installations, GE provides on – site commissioning services with certified engineers who ensure proper integration and calibration of the IS220PTURH1A within the turbine control system.

Customers also have access to GE’s extensive online knowledge base, which contains user manuals, technical documentation, and troubleshooting guides related to the IS220PTURH1A and the Mark VIe control system. Training resources are available to help users become proficient in operating and maintaining the module. Although not always explicitly stated in the product documentation, GE may also offer extended warranty options in some regions or for certain customers, which could include additional services such as preventive maintenance checks and priority support. This comprehensive support structure ensures that the IS220PTURH1A continues to operate reliably throughout its service life.