Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | **GE IS230STAOH2A** |

| Manufacturer | General Electric (GE) |

| Product category | Isolated Analog Output DIN Rail Module |

| Series | Mark VIe |

| Number of analog outputs | 8 channels |

| Output signal type | 4-20mA DC |

| Accuracy | ±0.1% of full scale (FS) |

| Resolution | 16-bit DAC |

| Output load range | 0-600Ω |

| Isolation rating | 2kVrms (channel-to-channel) |

| Operating temperature range | -40°C to +70°C |

| Installation method | DIN rail mounting (35mm standard) |

| Safety certification | UL 508, CE, IEC 61508 SIL 2 |

| Physical size | 17.8 cm (W) × 33.0 cm (H) × 12.7 cm (D) |

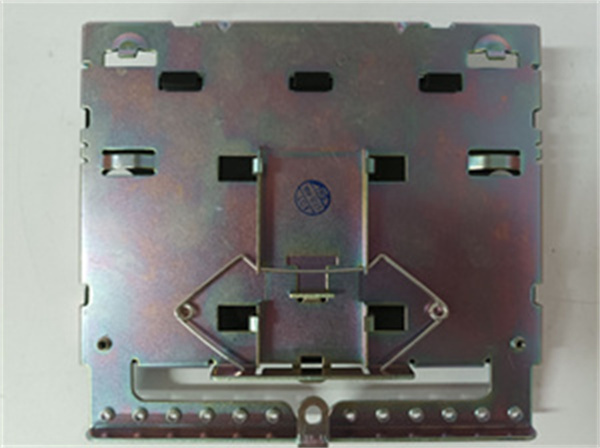

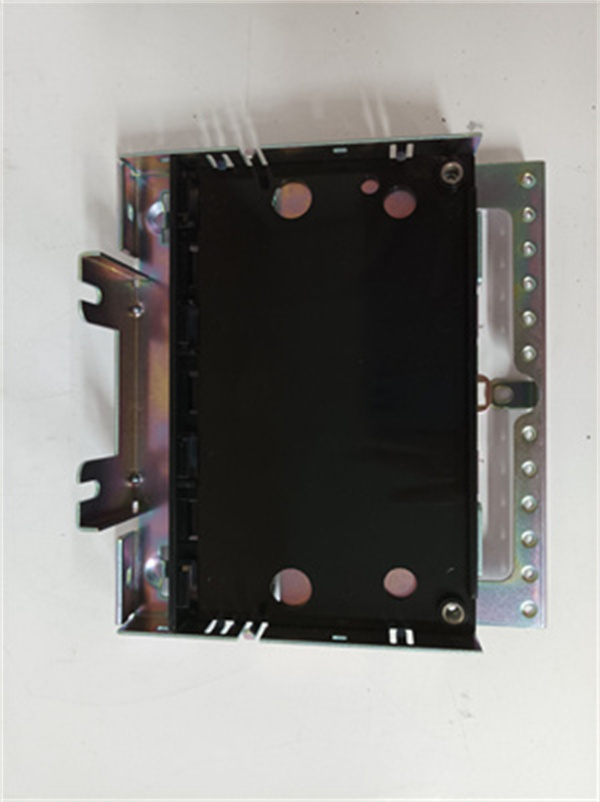

GE IS230STAOH2A

Product Introduction

The **GE IS230STAOH2A** is a high-performance isolated analog output DIN Rail Module under GE’s Mark VIe control system series, specifically engineered to convert digital control commands from the Mark VIe controller into precise analog signals for industrial actuators. As a critical execution component in automation systems, it serves as the vital link between the digital control layer and field devices such as control valves, variable frequency drives (VFDs), and positioners, ensuring accurate and reliable control of continuous process variables.

In process control scenarios requiring precise actuator regulation, the **GE IS230STAOH2A** excels in delivering stable 4-20mA DC output signals even in harsh industrial environments. Its 16-bit DAC resolution and high accuracy ensure that the analog output closely tracks the digital control commands, enabling fine-tuning of process parameters. By providing isolated channels and robust load compatibility, the **GE IS230STAOH2A** enhances system reliability and flexibility, making it an ideal choice for industries like power generation, chemical processing, and petroleum refining.

Core advantages and technical highlights

Precise Analog Output Performance: Equipped with a 16-bit digital-to-analog converter (DAC), the **GE IS230STAOH2A** achieves an accuracy of ±0.1% FS, ensuring that the output 4-20mA signals accurately reflect the controller’s digital commands. This level of precision is crucial for applications such as regulating the opening of control valves in chemical reactors or adjusting the speed of VFDs in pump systems, where small deviations in output signals can lead to significant process variations.

Reliable Channel Isolation & Load Compatibility: The **GE IS230STAOH2A** features 2kVrms channel-to-channel isolation, which effectively prevents signal crosstalk between channels and protects the module from damage caused by ground loops and voltage transients. It supports an output load range of 0-600Ω, enabling direct connection to a wide variety of field actuators without the need for additional signal amplifiers. This load flexibility makes it suitable for both low-impedance and high-impedance applications.

Industrial-Grade Environmental Resilience: Designed to operate in extreme temperature ranges from -40°C to +70°C, the **GE IS230STAOH2A** maintains stable performance in harsh industrial conditions. Its rugged construction and conformal coating on circuit boards protect against dust, moisture, and chemical corrosion, ensuring long-term reliability in environments such as power plant turbine rooms and chemical plant control cabinets. The module also complies with IEC 61000-4 EMC standards, resisting electromagnetic interference from nearby equipment.

Seamless Mark VIe Integration & Diagnostics: The **GE IS230STAOH2A** integrates seamlessly with the Mark VIe control system via the backplane, supporting automatic module recognition and configuration. It features built-in self-diagnostic functions that monitor output signal integrity and detect open-circuit or short-circuit faults, providing real-time alerts to the controller. LED status indicators for each channel offer visual feedback on output status, simplifying troubleshooting. The module also supports hot-swapping, allowing for quick replacement without shutting down the entire system.

Typical application scenarios

In coal-fired power plants, the **GE IS230STAOH2A** is used to control boiler feedwater valves and air dampers. It converts digital control commands from the Mark VIe controller into 4-20mA signals to regulate the opening of these valves, ensuring precise control of water flow and air supply to the boiler. This accurate regulation optimizes combustion efficiency, reduces fuel consumption, and maintains stable steam pressure. The module’s isolation rating protects against electrical noise from boiler equipment, ensuring reliable signal transmission.

In chemical processing plants, the **GE IS230STAOH2A** controls the speed of mixer motors and the position of dosing pumps via VFDs. It sends precise 4-20mA signals to the VFDs, adjusting the motor speed to maintain optimal mixing intensity or chemical dosing rates. When processing sensitive materials that require strict parameter control, the module’s high accuracy ensures that the process variables stay within the specified range, improving product quality and reducing waste. Its ability to withstand corrosive environments makes it suitable for installation in chemical plant control areas.

Related model recommendations

**GE IS230TBAIH2C**: A Mark VIe isolated analog input module that collects field sensor data and transmits it to the controller, forming a complete analog control loop with the **GE IS230STAOH2A**.

**GE IS230TDBTH6A**: A Mark VIe discrete I/O terminal board that provides wiring interfaces for actuators connected to the **GE IS230STAOH2A**, simplifying field wiring.

**GE IS230STAOH3A**: An upgraded version of the **GE IS230STAOH2A** with 16 analog output channels, designed for large-scale analog control applications.

**GE IS230TCATH1A**: A Mark VIe Ethernet/IP communication module that enables the controller to receive remote control commands for the **GE IS230STAOH2A**.

**GE IS230TSPRH1CDIN**: A Mark VIe signal processing module that conditions analog signals before they are sent to the **GE IS230STAOH2A** in complex signal environments.

**GE IS230STTCH2AD**: A Mark VIe mixed digital I/O module that complements the **GE IS230STAOH2A** in systems requiring both analog and digital control.

**GE IS230TCISH6C**: A Mark VIe multi-protocol communication module that allows the **GE IS230STAOH2A**-controlled system to connect to Modbus TCP/PROFINET networks.

GE IS230STAOH2A

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the **GE IS230STAOH2A**, ensure the control cabinet is clean, dry, and free from corrosive gases. The ambient temperature should be within -40°C to +70°C. Required tools include a 35mm DIN rail cutter, Phillips screwdriver, wire stripper, and precision multimeter. Disconnect the system power supply before installation. Align the module with the DIN rail, push until it locks into place, and secure with side screws. Use shielded twisted-pair cables for actuator wiring, connecting the cable shield to the cabinet ground. Verify the load impedance of connected actuators is within the 0-600Ω range before powering on.

Maintenance suggestions: Conduct monthly visual inspections of the **GE IS230STAOH2A** to check for loose wiring, damaged LED indicators, or abnormal heating. Clean the module surface and ventilation slots quarterly using compressed air (max pressure 0.5MPa). Calibrate the module annually using a standard current meter, adjusting the output signals to match the controller’s digital commands per the Mark VIe system manual. In case of output signal drift or fault alerts, first check the actuator and wiring, then use the module’s diagnostic functions to isolate issues. Replace damaged modules with genuine GE spares to ensure compatibility and performance.

Service and guarantee commitment

The **GE IS230STAOH2A** comes with a 12-month manufacturer’s warranty covering material and workmanship defects. GE’s global technical support team provides 24/7 assistance via email, online portals, and phone, offering calibration guides, troubleshooting solutions, and firmware updates. For on-site service needs, certified GE engineers can be dispatched to customer locations within 48 hours in major industrial regions. Extended warranty plans up to 3 years and customized preventive maintenance services are available to maximize the module’s operational lifespan. GE is committed to delivering high-precision, reliable analog output modules to support customers’ industrial automation control needs.