Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | **GE IS230STCIH6A** |

| Manufacturer | General Electric (GE) |

| Product category | Industrial Ethernet Communication Interface Module |

| Series | Mark VIe |

| Supported protocols | Ethernet/IP, Modbus TCP |

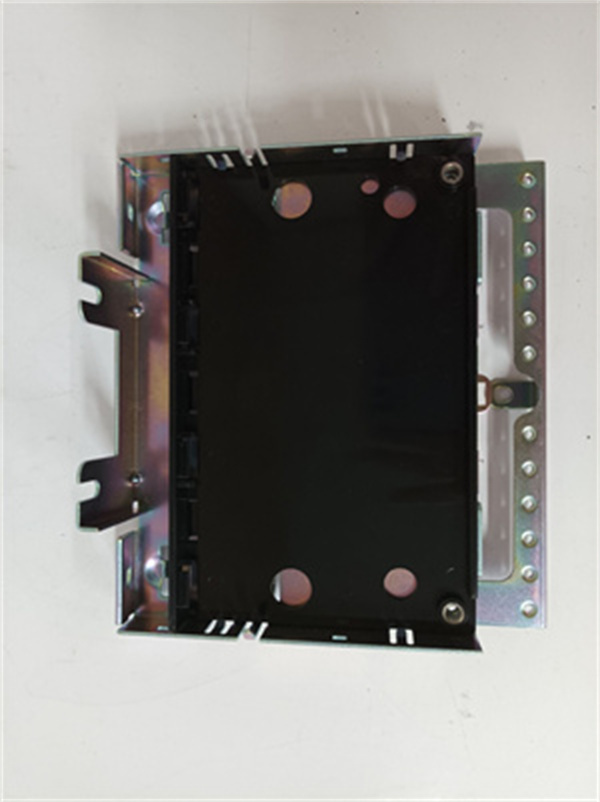

| Ethernet ports | 2 x 10/100 Mbps RJ45 |

| Data transfer rate | Up to 100 Mbps |

| Connection method | Backplane connection (Mark VIe chassis) + Ethernet cable |

| Operating temperature range | -40°C to +70°C |

| Isolation rating | 2kVrms (Ethernet ports to backplane) |

| Installation method | Mark VIe chassis mounting (slot-compatible) |

| Safety certification | UL 508, CE, IEC 61010-1 |

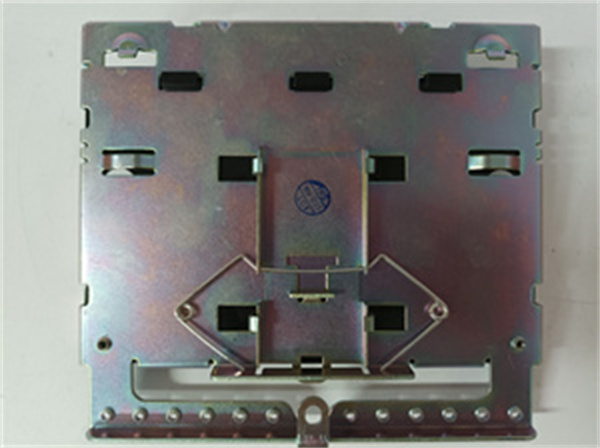

| Physical size | 10.16 cm (W) × 22.86 cm (H) × 12.7 cm (D) |

Product Introduction

The **GE IS230STCIH6A** is a dual-protocol industrial Ethernet communication interface module under GE’s Mark VIe control system series, engineered to enable seamless data exchange between Mark VIe I/O modules/controllers and upper-level industrial networks. As a core connectivity component, it serves as the bridge between distributed control units and supervisory systems (SCADA, MES), supporting Ethernet/IP and Modbus TCP to ensure compatible and efficient data transmission in medium-scale industrial environments.

In industrial digitization scenarios, the **GE IS230STCIH6A** plays a vital role in breaking down data silos between different system layers. Its dual Ethernet ports support basic network redundancy, ensuring uninterrupted communication even if one network path fails. By providing low-latency, dual-protocol data transmission, the **GE IS230STCIH6A** facilitates real-time monitoring, centralized control, and data analytics, making it a flexible choice for automation systems requiring connectivity with multiple network ecosystems.

Core advantages and technical highlights

Dual-Protocol Compatibility: The **GE IS230STCIH6A** natively supports both Ethernet/IP and Modbus TCP, two of the most widely used industrial Ethernet protocols. This dual-protocol capability allows it to seamlessly integrate with Allen-Bradley (Ethernet/IP) and third-party (Modbus TCP) devices/systems, eliminating the need for additional protocol converters. Users can switch between protocols via software configuration, enhancing system flexibility and reducing integration costs.

Reliable Redundant Communication: Equipped with 2 x 10/100 Mbps Ethernet ports, the **GE IS230STCIH6A** supports network redundancy modes such as dual-path backup. When the primary network fails, the module automatically switches to the standby port within milliseconds, minimizing communication downtime. This redundancy is critical for applications where continuous data transmission is essential, such as power generation and chemical processing.

Industrial-Grade Robustness: With a 2kVrms isolation rating between Ethernet ports and the backplane, the **GE IS230STCIH6A** effectively suppresses electrical noise, ground loops, and voltage transients common in industrial sites. It complies with IEC 61000-4 EMC standards, ensuring stable operation near motors, inverters, and other high-interference equipment. The -40°C to +70°C operating temperature range allows reliable performance in extreme climate conditions.

Seamless Mark VIe Integration: The **GE IS230STCIH6A** is fully compatible with the Mark VIe chassis, supporting hot-swapping for quick module replacement without system shutdown. It can be configured via GE’s Proficy Machine Edition software, which provides an intuitive interface for IP setting, protocol selection, and data mapping. The module’s auto-discovery feature enables upper-level systems to detect it automatically, simplifying commissioning.

Typical application scenarios

In medium-scale wind farms, the **GE IS230STCIH6A** connects Mark VIe I/O modules (monitoring wind turbine speed, blade angle, and power output) to a Modbus TCP SCADA system. It transmits real-time turbine data to the central monitoring station, allowing operators to optimize energy production and schedule maintenance. The dual Ethernet ports provide redundant communication, ensuring data transmission is not interrupted by network failures in remote wind farm locations.

In automotive component manufacturing plants, the **GE IS230STCIH6A** integrates Mark VIe control systems with both Ethernet/IP HMIs and Modbus TCP inventory management systems. It sends production line status data (e.g., machine running time, defect count) to the Modbus TCP inventory system and receives production scheduling commands from the Ethernet/IP HMI. This dual-protocol support streamlines data flow between different factory systems, improving production efficiency and inventory accuracy.

Related model recommendations

**GE IS230TCISH6C**: A Mark VIe multi-protocol module (Ethernet/IP, Modbus TCP, PROFINET) that upgrades the **GE IS230STCIH6A** with PROFINET support for complex networks.

**GE IS230TNTRHIC**: A Mark VIe digital input module that collects field sensor data and transmits it to the **GE IS230STCIH6A** for network communication.

**GE IS230STCIH8A**: An upgraded version of the **GE IS230STCIH6A** with 4 Ethernet ports, suitable for large-scale network topologies.

**GE IS230TDBTH6A**: A Mark VIe terminal board that provides wiring interfaces for I/O modules connected to the **GE IS230STCIH6A**.

**GE IS230TCATH1A**: A Mark VIe single-protocol (Ethernet/IP) module, a cost-effective alternative to the **GE IS230STCIH6A** for single-protocol environments.

**GE IS230TRLYH1B**: A Mark VIe digital output module that executes control commands received by the **GE IS230STCIH6A** from upper systems.

**GE IS230TBAIH2C**: A Mark VIe analog input module that sends processed analog data to the **GE IS230STCIH6A** for remote monitoring.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the **GE IS230STCIH6A**, power off the Mark VIe chassis and verify slot compatibility. Required tools include a Phillips screwdriver and ESD wristband. Clean the module and chassis slot to remove dust. Align the module with chassis guide rails, insert firmly until it clicks, and fasten front-panel screws. Use CAT5e shielded Ethernet cables to connect ports to the network switch (cable length ≤100m). Configure IP address and protocol via Proficy Machine Edition before system power-on.

Maintenance suggestions: Conduct monthly visual inspections of the **GE IS230STCIH6A** to check Ethernet port LEDs (link/activity) and secure connections. Use a network tester quarterly to verify communication stability. Clean ventilation holes and chassis slot with compressed air (max 0.5MPa) every six months. For communication faults, first check cables and switches, then use Proficy Machine Edition for diagnostics. Replace damaged modules with genuine GE spares and ensure firmware version consistency.

Service and guarantee commitment

The **GE IS230STCIH6A** comes with a 12-month manufacturer’s warranty covering material and workmanship defects. GE’s global technical support team provides 24/7 assistance via email, online portals, and phone, offering firmware updates, configuration guides, and troubleshooting solutions. On-site technical support is available within 48 hours in major industrial regions. Extended warranty plans up to 3 years and customized training services are offered to maximize operational reliability. GE is committed to delivering flexible, reliable communication modules for industrial automation needs.