Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

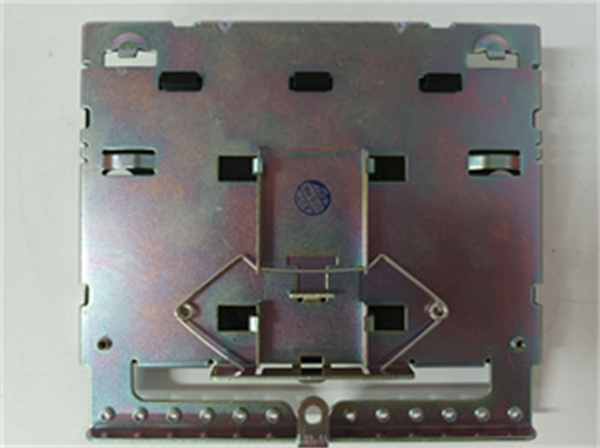

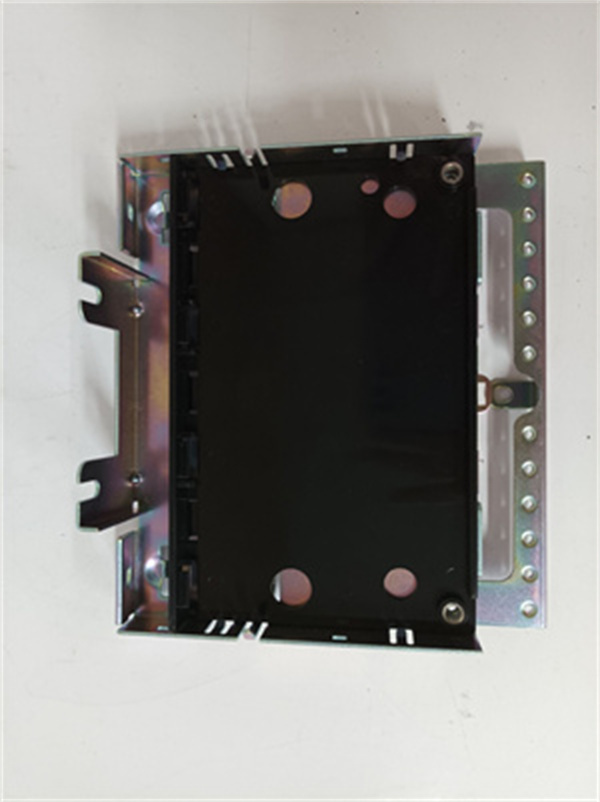

| Product model | **GE IS230STTCH2AD** |

| Manufacturer | General Electric (GE) |

| Product category | Mixed Digital I/O DIN Rail Module |

| Series | Mark VIe |

| Number of I/O channels | 16 channels (8 input/8 output) |

| Input signal type | Dry contact / 24V DC wet contact |

| Output type | Electromechanical relay (NO/NC) |

| Output rated voltage/current | 250V AC / 30V DC, 5A per channel |

| Operating temperature range | -40°C to +70°C |

| Isolation rating | 2kVrms (channel-to-channel) |

| Installation method | DIN rail mounting (35mm standard) |

| Safety certification | UL 508, CE, IEC 61508 SIL 2 |

| Physical size | 17.8 cm (W) × 33.0 cm (H) × 12.7 cm (D) |

GE IS230STTCH2AD

Product Introduction

The **GE IS230STTCH2AD** is a versatile mixed digital I/O DIN Rail Module under GE’s Mark VIe control system series, engineered to integrate both digital input and output functions in a single compact unit for industrial automation. As a dual-purpose front-end component, it serves as the connection hub between field sensors (limit switches, proximity sensors) and actuators (valves, motors), enabling bidirectional data flow—collecting device status signals while executing control commands from the Mark VIe controller.

In space-constrained automation systems, the **GE IS230STTCH2AD** eliminates the need for separate input and output modules, streamlining cabinet layout and reducing wiring complexity. Its 8 input/8 output channel configuration balances functionality and compactness, while the high isolation rating and rugged design ensure reliable operation in harsh industrial environments. By combining input acquisition and output control in one module, the **GE IS230STTCH2AD** simplifies system design, lowers overall costs, and enhances operational efficiency across diverse industries.

Core advantages and technical highlights

Integrated Mixed I/O Design: The **GE IS230STTCH2AD** combines 8 digital input and 8 digital output channels in a single DIN rail module, reducing the number of modules required in control cabinets by up to 50% compared to using separate input/output units. This integration not only saves valuable panel space but also simplifies wiring by minimizing inter-module connections, lowering installation time and potential wiring errors.

Flexible Input/Output Compatibility: On the input side, the **GE IS230STTCH2AD** supports both dry and 24V DC wet contacts, enabling direct connection to a wide range of field sensors without external signal conditioning. The output channels feature electromechanical relays with NO/NC contacts, supporting 250V AC/30V DC loads up to 5A per channel—suitable for controlling motors, valves, and alarm devices. Each output channel operates independently, allowing flexible assignment to different actuators.

Robust Isolation and Reliability: With a 2kVrms channel-to-channel isolation rating, the **GE IS230STTCH2AD** effectively prevents signal crosstalk and protects against ground loops, voltage transients, and electrical noise common in industrial settings. The relays offer a mechanical lifespan of over 10 million operations and electrical lifespan of 100,000 operations at full load, ensuring long-term reliability. The module’s operating temperature range of -40°C to +70°C and resistance to vibration and humidity make it suitable for extreme environments.

Seamless Mark VIe Integration & Diagnostics: The **GE IS230STTCH2AD** integrates seamlessly with the Mark VIe control system via the backplane, supporting automatic module recognition and configuration. It features LED status indicators for each input/output channel, providing real-time visual feedback on signal status. Built-in self-diagnostic functions detect relay failures and wiring issues, enabling technicians to quickly troubleshoot and minimize downtime. Hot-swappable capability allows for module replacement without system shutdown.

Typical application scenarios

In packaging machinery, the **GE IS230STTCH2AD** is used to monitor and control the production line. Its input channels collect status signals from photoelectric sensors (detecting package presence) and limit switches (indicating conveyor position), while the output channels control conveyor motors, sealing heaters, and label applicators. The integrated design saves space in the machine’s control cabinet, and its fast response ensures synchronized operation of packaging steps—reducing product waste and improving throughput.

In water treatment plants, the **GE IS230STTCH2AD** monitors and controls filtration systems. Input channels connect to pressure sensors (detecting filter clogging) and level switches (indicating tank levels), while output channels activate backwash pumps, solenoid valves, and alarm buzzers. When the module detects high filter pressure, it triggers the backwash pump via the output channel to clean the filter—ensuring continuous water treatment. Its isolation rating protects against electrical noise from pumps and motors, maintaining stable operation in the plant environment.

GE IS230STTCH2AD

Related model recommendations

**GE IS230TDBTH6A**: A Mark VIe discrete I/O terminal board that provides wiring interfaces for field sensors/actuators connected to the **GE IS230STTCH2AD**, simplifying field wiring.

**GE IS230TCATH1A**: A Mark VIe Ethernet/IP communication module that transmits I/O data from the **GE IS230STTCH2AD** to upper-level SCADA systems for remote monitoring.

**GE IS230STTCH3AD**: An upgraded version of the **GE IS230STTCH2AD** with 24 channels (12 input/12 output), designed for larger-scale mixed I/O applications.

**GE IS230TSPRH1CDIN**: A Mark VIe signal processing module that works with the **GE IS230STTCH2AD** when analog signals need conversion for mixed-signal systems.

**GE IS230TRLYH1B**: A Mark VIe digital output module that expands the output capacity of the **GE IS230STTCH2AD** in applications requiring more relays.

**GE IS230TNTRHIC**: A Mark VIe digital input module that complements the **GE IS230STTCH2AD** for projects needing additional input channels.

**GE IS230TCISH6C**: A Mark VIe multi-protocol communication module that enables the **GE IS230STTCH2AD** to connect to Modbus TCP/PROFINET networks.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the **GE IS230STTCH2AD**, ensure the control cabinet is clean, dry, and free from corrosive gases. The ambient temperature should be within -40°C to +70°C. Required tools include a 35mm DIN rail cutter, Phillips screwdriver, wire stripper, and multimeter. Disconnect system power before installation. Align the module with the DIN rail, push until it locks, and secure with side screws. Use shielded twisted-pair cables for sensor/actuator wiring, connecting the shield to cabinet ground. Label input/output wires clearly to match channel numbers on the module.

Maintenance suggestions: Conduct monthly visual inspections of the **GE IS230STTCH2AD** to check LED indicators, loose wiring, or abnormal heating. Clean the module surface and ventilation slots quarterly with compressed air (max 0.5MPa). Test relay contacts annually with a multimeter—replace the module if contact resistance exceeds 100mΩ. In case of input/output faults, first check field devices and wiring, then use Mark VIe diagnostics to isolate channel issues. Always use genuine GE spares for replacements to ensure compatibility and safety.

Service and guarantee commitment

The **GE IS230STTCH2AD** comes with a 12-month manufacturer’s warranty covering material and workmanship defects. GE’s global technical support team provides 24/7 assistance via email, online portals, and phone, offering installation guides, troubleshooting solutions, and firmware updates. For on-site service, certified GE engineers can be dispatched within 48 hours in major industrial regions. Extended warranty plans up to 3 years and customized maintenance services are available to maximize operational lifespan. GE is committed to delivering versatile, reliable mixed I/O modules to support customers’ efficient automation system design.