Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | **GE IS230TBAIH2C** |

| Manufacturer | General Electric (GE) |

| Product category | Isolated Analog Input DIN Rail Module |

| Series | Mark VIe |

| Number of analog inputs | 8 channels |

| Input signal type | 4-20mA DC / 0-10V DC (configurable) |

| Accuracy | ±0.05% of full scale (FS) |

| Resolution | 24-bit ADC |

| Operating temperature range | -40°C to +70°C |

| Isolation rating | 2kVrms (channel-to-channel) |

| Installation method | DIN rail mounting (35mm standard) |

| Safety certification | UL 508, CE, IEC 61508 SIL 2 |

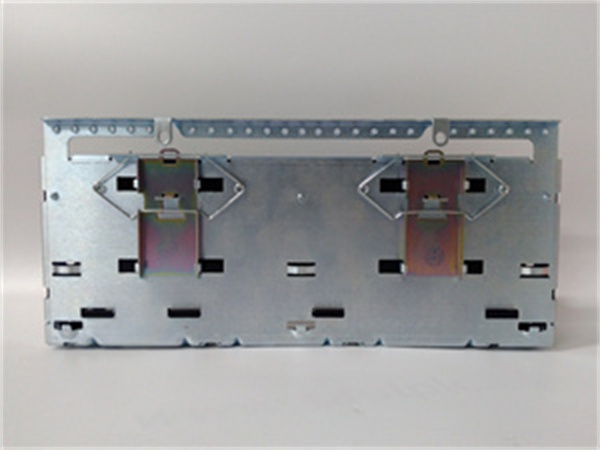

| Physical size | 17.8 cm (W) × 33.0 cm (H) × 12.7 cm (D) |

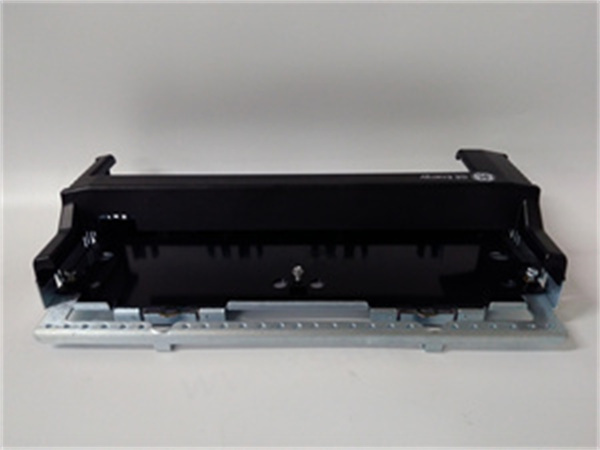

GE IS230TBAIH2C

Product Introduction

The **GE IS230TBAIH2C** is a high-precision isolated analog input DIN Rail Module under GE’s Mark VIe control system series, specifically engineered for accurate acquisition and reliable transmission of analog process signals in industrial automation. As a core front-end data acquisition component, it serves as the critical link between field sensors (such as pressure transmitters, temperature sensors, and flow meters) and the Mark VIe controller, converting continuous physical variables into digital data that the control system can analyze and act upon.

In precision-demanding industrial processes, the **GE IS230TBAIH2C** excels in capturing subtle changes in analog signals even amid harsh operational conditions. Its configurable input signal type (4-20mA/0-10V) ensures compatibility with a wide range of field sensors, while the 24-bit ADC and high isolation rating guarantee signal integrity and measurement accuracy. By providing high-fidelity analog data, the **GE IS230TBAIH2C** lays a solid foundation for precise process control, predictive maintenance, and operational efficiency across industries like power generation, petrochemicals, and pharmaceuticals.

Core advantages and technical highlights

Ultra-High Measurement Precision: Equipped with a 24-bit analog-to-digital converter and advanced signal conditioning circuitry, the **GE IS230TBAIH2C** achieves an exceptional accuracy of ±0.05% FS. This level of precision enables it to detect even the smallest fluctuations in process signals, such as minor pressure changes in chemical reactors or subtle temperature variations in turbine bearings, ensuring that the control system can make timely and accurate adjustments.

Configurable Signal Compatibility: The **GE IS230TBAIH2C** supports both 4-20mA DC current signals and 0-10V DC voltage signals, which can be configured per channel via software or hardware jumpers. This flexibility allows it to seamlessly connect with different types of field sensors without the need for additional signal conversion devices, reducing system complexity and cost. It is particularly suitable for mixed-sensor environments where both current and voltage output sensors are used.

Reliable Channel-to-Channel Isolation: With a 2kVrms channel-to-channel isolation rating, the **GE IS230TBAIH2C** effectively prevents signal crosstalk between channels and protects the module from damage caused by ground loops, voltage transients, and electrical noise. This isolation design not only enhances the reliability of signal acquisition but also ensures the safety of the entire control system, making it suitable for use in high-voltage industrial environments such as power plant switchyards and smelting facilities.

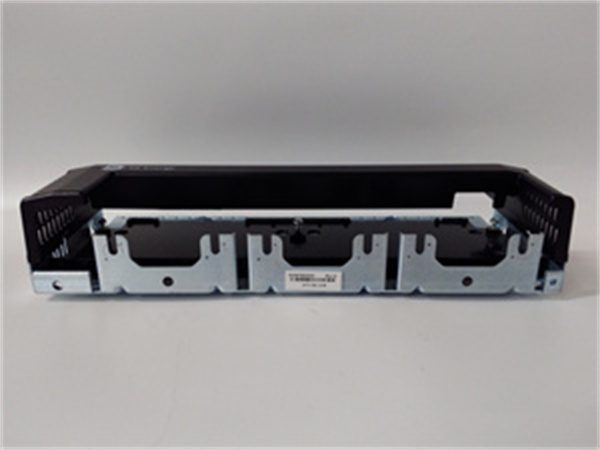

Seamless Mark VIe Integration & Easy Maintenance: The **GE IS230TBAIH2C** is fully compatible with the Mark VIe control system ecosystem, communicating seamlessly with controllers and other I/O modules via the system backplane. It supports hot-swapping for quick module replacement without shutting down the entire system, minimizing downtime. The module also features built-in self-diagnostic functions and LED status indicators for each channel, enabling technicians to quickly identify and troubleshoot issues during maintenance.

Typical application scenarios

In natural gas power plants, the **GE IS230TBAIH2C** is deployed to monitor key turbine parameters such as combustion chamber pressure, exhaust gas temperature, and lubricating oil pressure. It accurately acquires analog signals from specialized sensors and transmits them to the Mark VIe controller, which uses this data to optimize fuel injection and turbine speed, ensuring efficient power generation while preventing equipment overheating or damage. Its high precision ensures that even minor deviations in critical parameters are detected early.

In pharmaceutical manufacturing, the **GE IS230TBAIH2C** is used to monitor critical process variables in bioreactors, such as pH value, dissolved oxygen concentration, and temperature. These analog signals are transmitted to the control system to maintain optimal fermentation conditions, ensuring product quality and compliance with strict industry regulations. The module’s isolation capability prevents electrical interference from affecting sensitive bioprocesses, and its configurable signal input supports both current and voltage output sensors commonly used in pharmaceutical labs.

Related model recommendations

**GE IS230TNSVH3A**: A Mark VIe high-density digital output module that pairs with the **GE IS230TBAIH2C** to form a complete control loop, executing control commands based on the analog data acquired.

**GE IS230TDBTH6A**: A Mark VIe discrete I/O terminal board that provides wiring interfaces for field sensors connected to the **GE IS230TBAIH2C**, simplifying field wiring and maintenance.

**GE IS230TBAIH3C**: An upgraded version of the **GE IS230TBAIH2C** with 16 analog input channels, designed for large-scale automation projects requiring higher channel density.

**GE IS230TCATH1A**: A Mark VIe Ethernet/IP communication module that transmits the analog data acquired by the **GE IS230TBAIH2C** to upper-level SCADA systems for remote monitoring.

**GE IS230TSPRH1CDIN**: A Mark VIe signal processing module that works in tandem with the **GE IS230TBAIH2C** to amplify and filter weak analog signals from special sensors.

**GE IS230TRLYH1B**: A Mark VIe digital relay output module that controls field actuators based on the processed analog data from the **GE IS230TBAIH2C**.

**GE IS230TNPAH2A**: Another Mark VIe analog input module with different accuracy specifications, complementary to the **GE IS230TBAIH2C** in mixed-precision application scenarios.

GE IS230TBAIH2C

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the **GE IS230TBAIH2C**, ensure the control cabinet is clean, dry, and free from corrosive gases. The ambient temperature should be within -40°C to +70°C. Required tools include a 35mm DIN rail cutter, Phillips screwdriver, wire stripper, and precision multimeter. Disconnect the system power supply before installation. Align the module with the DIN rail, push until it locks into place, and secure with side screws. Use shielded twisted-pair cables for sensor wiring, and connect the cable shield to the cabinet ground to minimize electromagnetic interference. Configure the input signal type (4-20mA/0-10V) via jumpers before powering on.

Maintenance suggestions: Conduct monthly visual inspections of the **GE IS230TBAIH2C** to check for loose wiring, damaged LED indicators, or abnormal heating. Clean the module surface and ventilation slots quarterly using compressed air (max pressure 0.5MPa). Calibrate the module annually using a standard signal generator to maintain measurement accuracy, following the Mark VIe system manual. In case of signal drift or channel failure, first check the sensor and wiring, then use the module’s diagnostic functions to locate faults. Replace damaged modules with genuine GE spares to ensure compatibility and performance.

Service and guarantee commitment

The **GE IS230TBAIH2C** comes with a 12-month manufacturer’s warranty covering material and workmanship defects. GE’s global technical support team provides 24/7 assistance via email, online portals, and phone, offering calibration guides, troubleshooting advice, and firmware updates. For on-site service needs, certified GE engineers can be dispatched to customer locations within 48 hours in major industrial regions. Extended warranty plans up to 3 years and customized preventive maintenance services are available to maximize the module’s operational lifespan. GE is committed to delivering high-precision, reliable analog input modules to support customers’ industrial automation needs.