Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

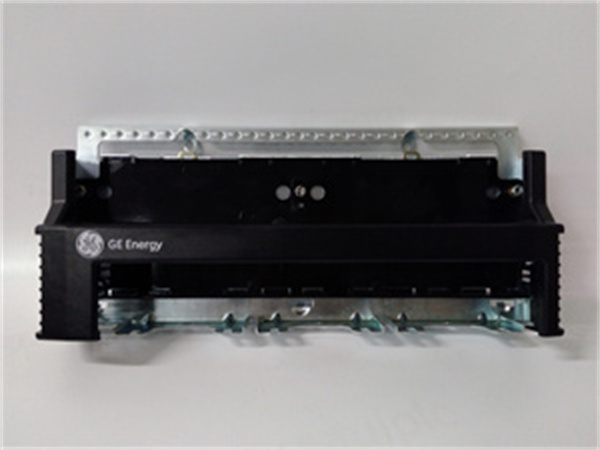

| Product model | **GE IS230TCATH1A** |

| Manufacturer | General Electric (GE) |

| Product category | Industrial Ethernet Communication Interface Module |

| Series | Mark VIe |

| Supported protocols | Ethernet/IP |

| Ethernet ports | 1 x 10/100 Mbps RJ45 |

| Data transfer rate | Up to 100 Mbps |

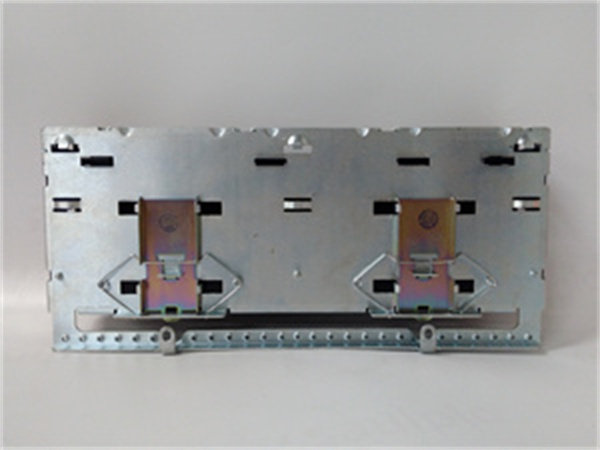

| Connection method | Backplane connection (Mark VIe chassis) + Ethernet cable |

| Operating temperature range | -40°C to +70°C |

| Isolation rating | 1.5kVrms (Ethernet port to backplane) |

| Installation method | Mark VIe chassis mounting (slot – compatible) |

| Safety certification | UL 508, CE, IEC 61010 – 1 |

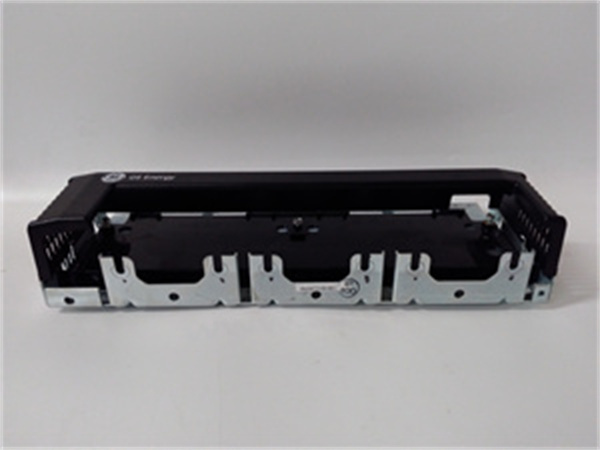

| Physical size | 10.16 cm (W) × 22.86 cm (H) × 12.7 cm (D) |

Product Introduction

The **GE IS230TCATH1A** is a cost-effective industrial Ethernet communication interface module under GE’s Mark VIe control system series, specifically designed for reliable data exchange between Mark VIe I/O modules/controllers and Ethernet/IP-based upper-level industrial networks. As a streamlined connectivity component in automation systems, it serves as a dedicated bridge between distributed control units and Ethernet/IP supervisory systems (such as SCADA, HMI), ensuring stable and efficient data transmission in small to medium-sized industrial environments.

In industrial control scenarios requiring simple and focused communication, the **GE IS230TCATH1A** plays a key role in enabling seamless data interaction between field-level devices and upper monitoring systems. Its compact design optimizes chassis space utilization, while its dedicated Ethernet/IP support ensures deep compatibility with Allen-Bradley and other Ethernet/IP ecosystem devices. By providing low-latency data transmission, the **GE IS230TCATH1A** facilitates real-time monitoring and basic control functions, making it an ideal choice for cost-sensitive and protocol-specific automation projects.

Core advantages and technical highlights

Dedicated Ethernet/IP Reliability: The **GE IS230TCATH1A** is optimized for Ethernet/IP communication, supporting CIP (Common Industrial Protocol) for seamless integration with Ethernet/IP-enabled PLCs, SCADA systems, and HMIs. Its protocol-specific firmware ensures stable data exchange with minimal packet loss, making it suitable for applications where Ethernet/IP is the standard network architecture, such as food and beverage processing lines and small-scale power distribution systems.

Compact and Space-Saving Design: With a slimmer depth (12.7 cm) compared to multi-port modules, the **GE IS230TCATH1A** occupies less space in the Mark VIe chassis, allowing for more I/O modules to be installed in the same cabinet. This compact form factor is particularly advantageous in control panels with limited space, such as machine-mounted control boxes and small-scale automation cabinets.

Robust Industrial-Grade Performance: Featuring a 1.5kVrms isolation rating between the Ethernet port and backplane, the **GE IS230TCATH1A** effectively resists electrical noise and ground loops in industrial environments. It complies with IEC 61000-4 EMC standards, ensuring stable operation in the presence of electromagnetic interference from nearby motors, inverters, and other industrial equipment. The operating temperature range of -40°C to +70°C allows it to work reliably in extreme climate conditions.

Simplified Configuration and Integration: The **GE IS230TCATH1A** seamlessly integrates with the Mark VIe chassis and supports hot-swapping for quick maintenance. It can be configured via GE’s Proficy Machine Edition software, which provides a user-friendly interface for IP address setting, data tag mapping, and communication diagnostics. The module’s auto-discovery feature enables upper-level Ethernet/IP systems to detect it automatically, reducing commissioning time and complexity.

Typical application scenarios

In small-scale solar power plants, the **GE IS230TCATH1A** is used to connect Mark VIe I/O modules (monitoring solar panel voltage, current, and inverter status) to an Ethernet/IP SCADA system. It transmits real-time energy production data and equipment status via Ethernet/IP to the central monitoring station, allowing operators to track system performance and troubleshoot minor issues remotely. Its compact design fits well in the limited space of solar inverter control cabinets.

In food and beverage packaging lines, the **GE IS230TCATH1A** connects Mark VIe digital I/O modules (controlling conveyor belts, packaging machines, and sensors) to an Ethernet/IP HMI. It sends packaging count, machine running status, and fault alerts to the HMI for operator monitoring, while receiving control commands (such as start/stop and speed adjustment) from the HMI. Its Ethernet/IP specialization ensures compatibility with Allen-Bradley PLCs commonly used in food industry automation, and its anti-interference capability maintains stable communication near metal detectors and packaging equipment.

Related model recommendations

**GE IS230TCISH6C**: A Mark VIe multi-protocol communication module (Ethernet/IP, Modbus TCP, PROFINET), serving as the upgraded version of the **GE IS230TCATH1A** for complex multi-protocol environments.

**GE IS230TNTRHIC**: A Mark VIe isolated digital input module that pairs with the **GE IS230TCATH1A** to collect field sensor data and transmit it to Ethernet/IP supervisory systems.

**GE IS230TCATH2A**: A dual-port version of the **GE IS230TCATH1A** with 2 Ethernet/IP ports, supporting basic network redundancy for critical single-protocol applications.

**GE IS230TDBTH6A**: A Mark VIe discrete I/O terminal board that provides wiring interfaces for field devices connected to I/O modules, working in tandem with the **GE IS230TCATH1A** in the control system.

**GE IS230TRLYH1B**: A Mark VIe digital relay output module that executes control commands received by the **GE IS230TCATH1A** from Ethernet/IP upper systems.

**GE IS230TNPAH2A**: A Mark VIe analog input module that transmits processed analog data (e.g., temperature, pressure) to the **GE IS230TCATH1A** for Ethernet/IP communication.

**GE IS230TCICH1A**: A Mark VIe Ethernet/IP communication module with enhanced diagnostic functions, complementary to the **GE IS230TCATH1A** in applications requiring advanced troubleshooting.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the **GE IS230TCATH1A**, power off the Mark VIe chassis and verify the slot compatibility (Mark VIe standard slot). Required tools include a Phillips screwdriver and ESD wristband. Clean the module and chassis slot to remove dust or debris. Align the module with the chassis guide rails, insert firmly until it clicks into place, and fasten the front-panel screws. Use CAT5 or higher-grade shielded Ethernet cables to connect the module’s RJ45 port to the network switch, ensuring cable length does not exceed 100 meters. Configure the module’s IP address via Proficy Machine Edition software prior to system power-on.

Maintenance suggestions: Conduct monthly visual inspections of the **GE IS230TCATH1A** to check the Ethernet port LED status (link/activity) and ensure secure cable connections. Use a network tester quarterly to verify Ethernet/IP communication stability. Clean the module’s ventilation openings and chassis slot with compressed air (max pressure 0.5MPa) every six months to prevent dust buildup. In case of communication issues, first inspect the Ethernet cable and switch, then use Proficy Machine Edition to run the module’s built-in diagnostics. Replace damaged modules with genuine GE spares and ensure firmware version consistency with the Mark VIe system.

Service and guarantee commitment

The **GE IS230TCATH1A** comes with a 12-month manufacturer’s warranty covering material and workmanship defects. GE’s global technical support team offers 24/7 assistance via email, online portals, and phone, providing firmware updates, configuration guides, and Ethernet/IP troubleshooting support. For batch deployments, we offer customized training on module integration and maintenance. Extended warranty plans up to 3 years are available to enhance long-term operational reliability. GE is committed to delivering cost-effective, high-performance communication modules to support customers’ simple and efficient industrial automation needs.