Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

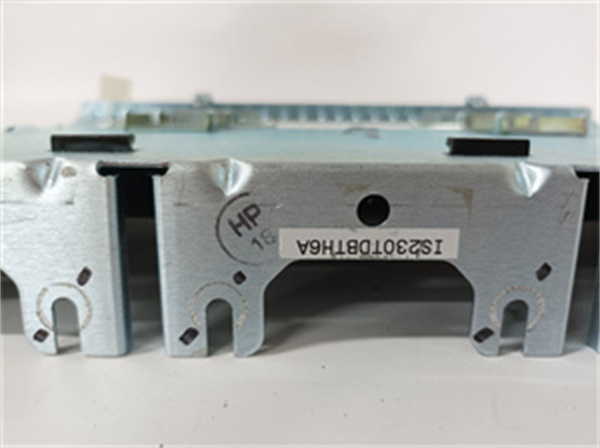

| Product model | **GE IS230TDBTH6A** |

| Manufacturer | General Electric (GE) |

| Product category | Discrete I/O Terminal Board |

| Series | Mark VIe |

| Number of terminal points | 32 points (16 input/16 output) |

| Terminal type | Spring – clamp terminals |

| Wire size range | 24 – 12 AWG (0.2 – 4.0 mm²) |

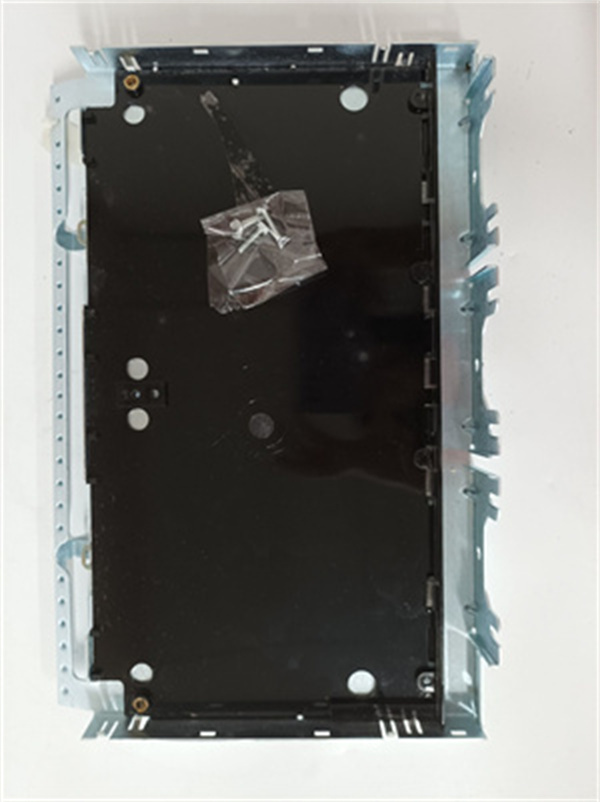

| Connection method | Plug – in connector (compatible with Mark VIe I/O modules) |

| Operating temperature range | -40°C to +70°C |

| Isolation rating | 2.5kVrms (module to terminal) |

| Installation method | DIN rail mounting (35mm standard) / Panel mounting |

| Safety certification | UL 508, CE, IEC 60947 – 1 |

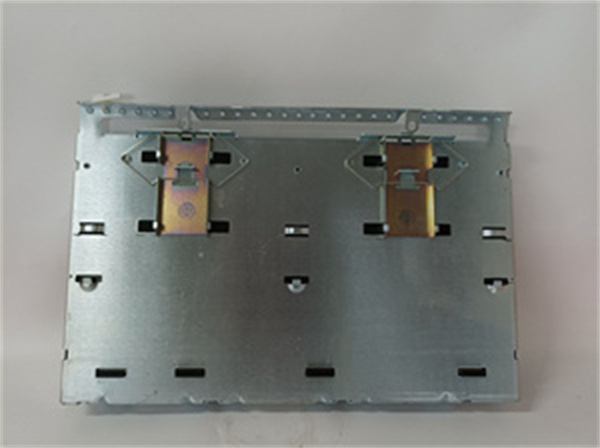

| Physical size | 22.86 cm (W) × 15.24 cm (H) × 5.08 cm (D) |

GE IS230TDBTH6A

Product Introduction

The **GE IS230TDBTH6A** is a high – performance discrete I/O terminal board under GE’s Mark VIe control system series, specifically designed to simplify field wiring and enhance connection reliability for industrial automation I/O modules. As a key interface component between field devices and Mark VIe I/O modules, it provides standardized terminal points for connecting sensors, actuators, and other field equipment, while ensuring electrical isolation and signal integrity in harsh industrial environments.

In complex automation systems, the **GE IS230TDBTH6A** plays a crucial role in streamlining wiring management. Its integrated spring – clamp terminals eliminate the need for traditional screw terminals, reducing wiring time and minimizing the risk of loose connections caused by vibration. By acting as an intermediate connection hub, the **GE IS230TDBTH6A** simplifies maintenance and troubleshooting, allowing technicians to quickly access and test field connections without disassembling the entire I/O module assembly.

Core advantages and technical highlights

Efficient Wiring Management: The **GE IS230TDBTH6A** features 32 spring – clamp terminal points (16 input/16 output), which can simultaneously connect multiple field devices. The spring – clamp design enables tool – free wiring for 24 – 12 AWG wires, reducing wiring time by up to 50% compared to traditional screw terminals. Each terminal is clearly labeled with input/output identifiers, making wiring configuration and error checking more intuitive.

Reliable Connection and Isolation: With a 2.5kVrms isolation rating between the terminal board and connected I/O modules, the **GE IS230TDBTH6A** effectively prevents electrical noise and voltage transients from interfering with the control system. The spring – clamp terminals provide consistent contact pressure, ensuring stable connections even in high – vibration environments such as turbine control cabinets. Additionally, the terminals are resistant to corrosion and oxidation, extending the service life of the connection points.

Flexible Installation and Compatibility: The **GE IS230TDBTH6A** supports both DIN rail mounting and panel mounting, adapting to different control cabinet layouts. It is fully compatible with all Mark VIe discrete I/O modules, such as the IS230TNTRHIC (digital input module) and IS230TRLYH1B (digital output module), through a plug – in connector interface. This plug – and – play compatibility allows for quick module replacement and system expansion without rewiring field devices.

Enhanced Maintenance Convenience: The **GE IS230TDBTH6A** is designed with maintenance in mind. It features test points for each terminal, enabling technicians to measure signal levels directly on the terminal board without disconnecting field wires. The compact and modular design also provides clear access to all terminals, reducing the time required for troubleshooting and connection inspections. Additionally, the terminal board’s durable plastic housing protects internal components from dust and mechanical damage.

Typical application scenarios

In power plant turbine control systems, the **GE IS230TDBTH6A** is used to connect limit switches, temperature sensors, and valve position feedback devices to Mark VIe digital input modules. It simplifies the wiring between field devices located in turbine enclosures and the I/O modules in the main control cabinet, reducing the complexity of cable management. During maintenance, technicians can easily test the input signals from turbine sensors using the terminal board’s test points, accelerating fault diagnosis.

In petrochemical refinery DCS systems, the **GE IS230TDBTH6A** serves as the connection hub for pipeline valve actuators, pump status sensors, and alarm devices. It connects these field devices to Mark VIe digital output modules (such as IS230TRLYH1B) and input modules, ensuring reliable signal transmission in environments with high electrical noise and chemical vapors. The terminal board’s corrosion – resistant terminals and robust housing make it suitable for long – term operation in refinery control rooms.

GE IS230TDBTH6A

Related model recommendations

**GE IS230TNTRHIC**: A Mark VIe isolated digital input module that works with the **GE IS230TDBTH6A** to collect status signals from field sensors, with the terminal board providing wiring interfaces.

**GE IS230TRLYH1B**: A Mark VIe digital relay output module that pairs with the **GE IS230TDBTH6A** to control field actuators, using the terminal board for output wiring connections.

**GE IS230TDBTH8A**: An upgraded version of the **GE IS230TDBTH6A** with 48 terminal points, suitable for large – scale I/O systems requiring more connection points.

**GE IS230TSPRH1CDIN**: A Mark VIe signal processing module that can be connected to the **GE IS230TDBTH6A** when analog signals need to be converted and processed before entering the control system.

**GE IS230TCICH1A**: A Mark VIe communication interface module that, when used with the **GE IS230TDBTH6A** – connected I/O system, enables remote monitoring and data transmission via Ethernet/IP networks.

**GE IS230TDBTH4A**: A compact version of the **GE IS230TDBTH6A** with 16 terminal points, designed for small – scale automation systems with limited wiring needs.

**GE IS230SNIDH1A**: An isolated digital input module that complements the **GE IS230TDBTH6A** in applications requiring high – density digital input connections.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the **GE IS230TDBTH6A**, ensure the control cabinet is clean, dry, and free from corrosive gases. The ambient temperature should be within -40°C to +70°C. Required tools include a DIN rail cutter (for DIN rail mounting), Phillips screwdriver, wire stripper, and label maker. Disconnect the system power supply before installation. For DIN rail mounting, attach the terminal board to a 35mm standard DIN rail; for panel mounting, use M4 screws to secure it to the panel. Ensure the plug – in connector is aligned with the corresponding Mark VIe I/O module before mating.

Maintenance suggestions: Perform quarterly visual inspections of the **GE IS230TDBTH6A** to check for loose terminals, damaged labels, or signs of corrosion. Use a soft brush or compressed air (max pressure 0.5MPa) to clean dust from the terminal board surface. When troubleshooting, use a multimeter to test signal levels at the terminal test points. If a terminal becomes damaged, replace the entire terminal board (do not attempt to repair individual terminals). Always use genuine GE plug – in connectors to ensure compatibility and electrical safety when replacing the terminal board.

Service and guarantee commitment

The **GE IS230TDBTH6A** comes with a 12 – month manufacturer’s warranty covering defects in materials and workmanship. GE’s global technical support team provides 24/7 assistance via email, online portals, and phone, offering wiring diagrams, installation guides, and troubleshooting advice. For bulk orders, GE offers customized training services on terminal board installation and maintenance. We also provide extended warranty plans up to 3 years to ensure long – term operational reliability. GE is committed to delivering high – quality terminal board products and professional after – sales support to meet customer automation system needs.