Description

Detailed Parameter Table

| Parameter name | Parameter value |

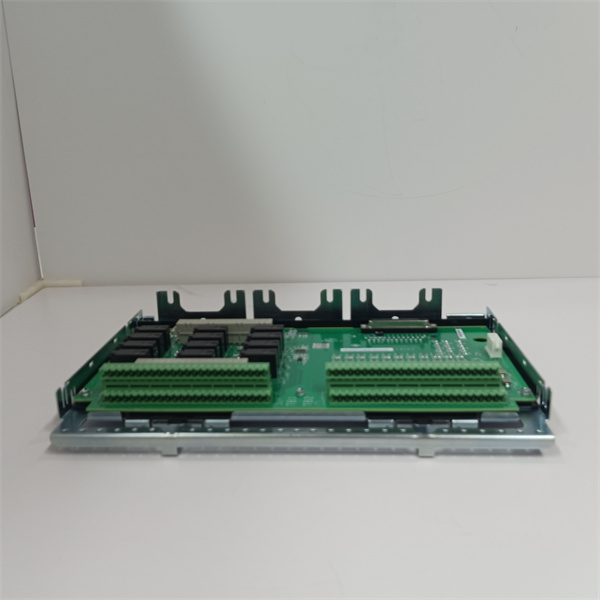

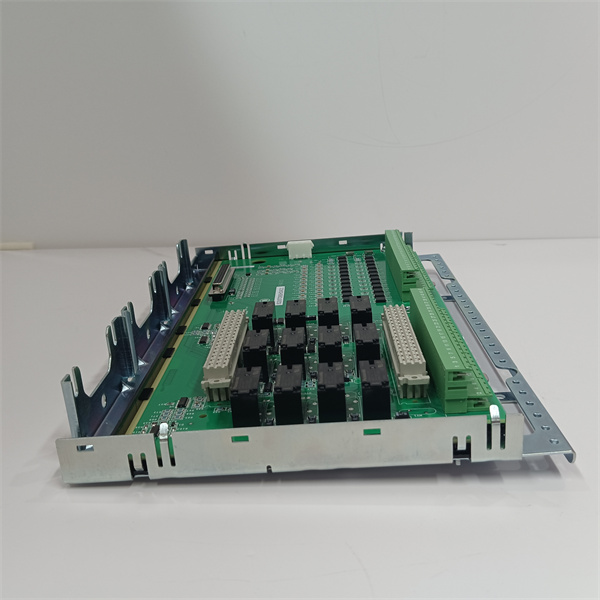

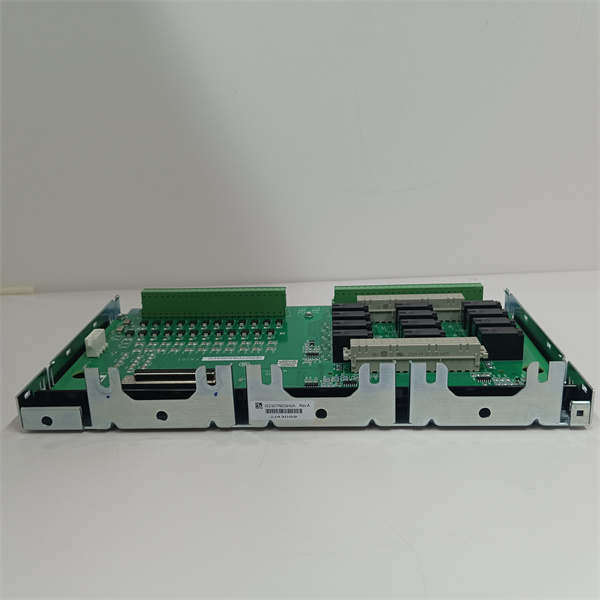

| Product model | IS230TNDSH2A |

| Manufacturer | GE (General Electric) |

| Product category | Discrete Signal Module within Mark VI Series |

| Function | Primarily for digital input/output signal processing |

| Input/Output Configuration | Supports multiple I/O configurations adaptable to various application needs |

| Interface | Compatible with Mark VI control system interfaces |

| Signal Types | Handles digital input/output signals, enabling connection with sensors, actuators, etc. |

| Mounting | Designed for easy installation, likely in a control panel setup |

| Operating Temperature | Suitable for typical industrial operating temperatures (to be specified precisely in product documentation, usually a wide range to endure industrial environments) |

| Power Requirements | Specific power requirements to be detailed in the product manual, optimized for industrial power supplies |

| Module Design | Modular, facilitating replacement and maintenance |

GE IS230TNDSH2A

Product Introduction

GE’s IS230TNDSH2A is a pivotal discrete signal module nestled within the advanced Mark VI Series of control systems. This series is renowned for its high – performance, reliability, and scalability, making it a go – to solution for a wide array of industrial applications, especially in power generation and industrial automation.

The IS230TNDSH2A serves as a crucial link between external devices such as sensors and actuators and the overarching control system. By efficiently processing digital input and output signals, it enables seamless communication and control within industrial setups. Whether it’s gathering data from sensors about the status of machinery or sending out control signals to actuators to adjust equipment operations, this module plays a fundamental role in ensuring smooth industrial processes.

Core Advantages and Technical Highlights

High – speed signal processing: Employing state – of – the – art digital signal processing techniques, the IS230TNDSH2A can rapidly and accurately handle a large volume of discrete signals. In high – speed manufacturing lines, for example, it can quickly respond to sensor inputs indicating the position of products on a conveyor belt and send out appropriate control signals to robotic arms for precise pick – and – place operations.

Exceptional reliability: Built with industrial – grade components and a robust design, this module exhibits excellent resistance to electromagnetic interference and mechanical vibrations. In power plants, where there are high – voltage electrical systems and heavy machinery operating in close proximity, the IS230TNDSH2A can maintain stable operation, ensuring continuous and reliable monitoring and control of critical equipment.

Flexible configuration options: The module supports a wide range of I/O configurations. This flexibility allows system integrators to customize the module according to the specific requirements of different industrial applications. For instance, in a chemical plant, depending on the number and type of sensors and actuators used in different process units, the IS230TNDSH2A can be configured to interface with them effectively.

Ease of maintenance: Thanks to its modular design, the IS230TNDSH2A is extremely user – friendly when it comes to maintenance. In the event of a component failure, technicians can easily identify and replace the faulty module without having to disrupt the entire control system. This reduces downtime significantly, leading to increased productivity in industrial operations.

Typical Application Scenarios

Power generation – gas turbine control: In gas turbine power plants, the IS230TNDSH2A is used to monitor and control various parameters. It receives digital signals from sensors that measure temperature, pressure, and speed within the gas turbine. Based on these inputs, it sends out control signals to actuators that adjust the fuel supply, blade angles, and other critical components. This ensures optimal performance, efficiency, and safety of the gas turbine.

Industrial manufacturing – automated production lines: In automotive manufacturing plants, for example, the module is used to manage the operation of automated production lines. It processes signals from sensors that detect the presence of parts, the position of robotic arms, and the status of conveyor belts. By coordinating these signals, it enables the smooth flow of production, from the initial assembly of components to the final inspection of finished vehicles.

Process industries – chemical and petrochemical plants: In chemical plants, the IS230TNDSH2A is involved in controlling chemical reactions and monitoring the flow of materials. It connects with sensors that measure the concentration of chemicals, the pressure in reaction vessels, and the temperature of cooling systems. The module then sends out control signals to valves, pumps, and other actuators to regulate the chemical processes, ensuring product quality and plant safety.

GE IS230TNDSH2A

Related Model Recommendations

IS230TDBSH2A: A simplex discrete I/O terminal board within the same Mark VI family. It has a specific number of input channels (e.g., 24) and relay channels (e.g., 12), which might be more suitable for applications with lower I/O requirements or where a more basic configuration suffices.

IS230SRTDH2A: Although not a discrete signal module in the same sense, it can be used in conjunction with the IS230TNDSH2A in certain applications. For example, in a system where temperature monitoring using RTDs is crucial, the IS230SRTDH2A can handle the temperature – related signals, while the IS230TNDSH2A manages other discrete signals.

IS200WNPSH1ABA: This industrial automation module from GE has I/O signal processing capabilities and can be considered as an alternative or complementary option in some setups. It has a different set of features, such as a specific number of digital and analog input/output channels, which might be more appropriate for applications with different signal – handling requirements.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installation, ensure that the control system where the IS230TNDSH2A is to be installed is powered off. Check the physical dimensions of the module and the available mounting space in the control panel to ensure a proper fit. Use appropriate anti – static equipment, such as wrist straps and mats, to prevent electrostatic discharge during handling. Verify that the interface connectors on the module match those of the control system.

Maintenance suggestions: Regularly inspect the module for any signs of physical damage, such as cracks or loose connections. Check the status indicators (if available) to ensure normal operation. In case of a suspected malfunction, use GE – provided diagnostic tools to identify the problem. If a component needs replacement, always use genuine GE replacement parts to maintain the integrity and performance of the module. Keep the module clean and free from dust and debris, especially in dusty industrial environments.

Commissioning process: After installation, power on the control system. Use the appropriate software tools to configure the IS230TNDSH2A according to the application requirements. Test the input and output signals by simulating sensor inputs and observing the corresponding actuator responses. Calibrate the module if necessary, following the procedures outlined in the product manual. Ensure that all communication interfaces are working correctly by sending and receiving test data.

Service and Guarantee Commitment

GE offers a comprehensive service and guarantee package for the IS230TNDSH2A. The product typically comes with a standard warranty period, during which GE will repair or replace the module free of charge in case of manufacturing defects. GE’s global technical support team is available around the clock to provide assistance. They can offer remote troubleshooting, answer technical questions, and provide software updates if applicable. For more complex issues, GE can dispatch trained technicians to the site for on – site support. Additionally, extended warranty options may be available for customers who want long – term protection for their investment. This commitment to service and support reflects GE’s confidence in the quality and reliability of the IS230TNDSH2A and its dedication to customer satisfaction in industrial applications.