Description

Detailed Parameter Table

| Parameter name | Parameter value |

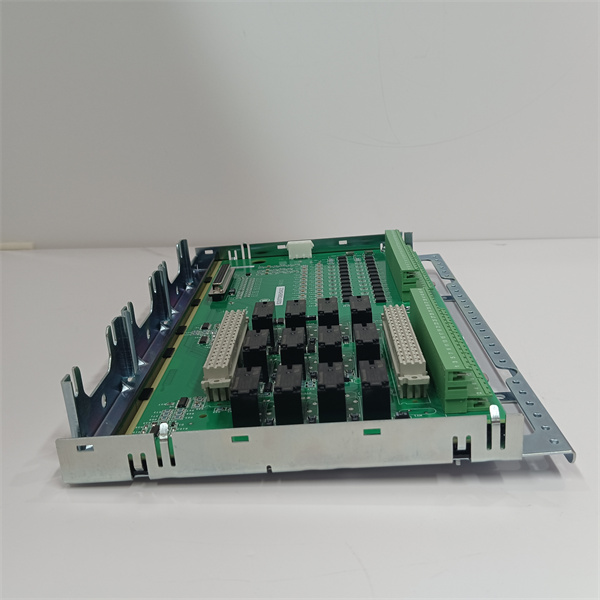

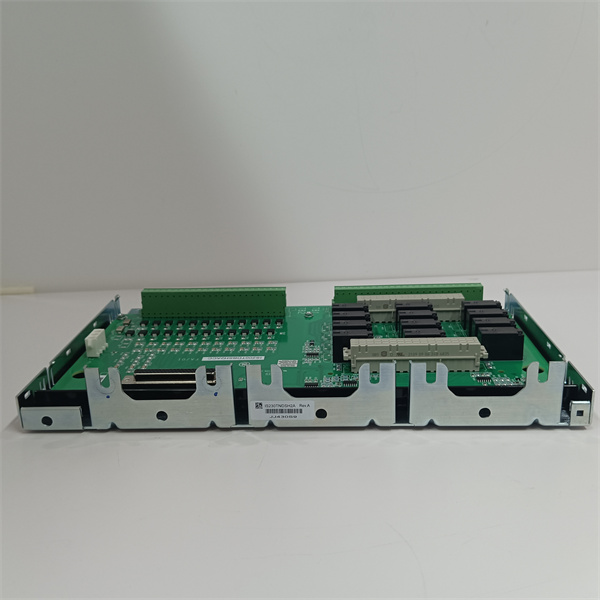

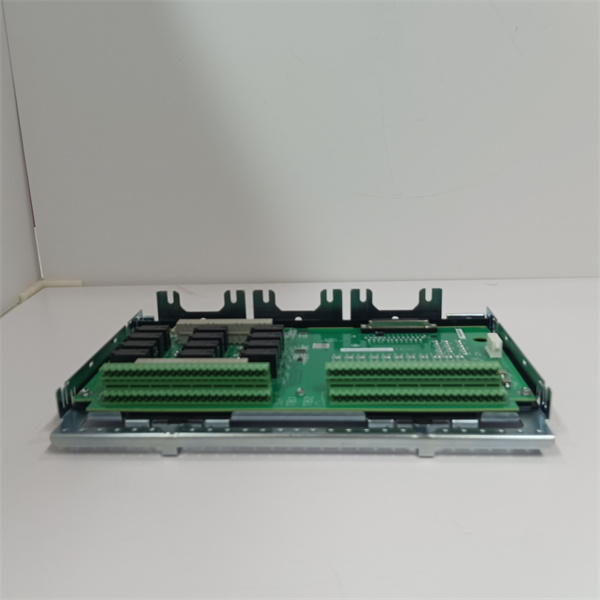

| Product model | IS230TNDSH2A |

| Manufacturer | GE (General Electric) |

| Product category | Terminal Board |

| Series | Mark VIe |

| Function | Facilitates connection and signal management in control systems |

| Number of input channels | 24 |

| Number of relay channels | 12 |

| Trip solenoid rating | 125 V DC |

| Span | – 8 mV to +45 mV |

| Power supply voltage | 28 V DC |

| Voltage range | 18 – 32 VDC |

| Mounting | DIN – rail mounting |

| Technology | Surface mount |

| Operating temperature | 40 to 70 °C |

| Size | 168 x 150 x 55 mm |

| Weight | 0.4 kg |

| Country of origin | United States |

| Warranty | 12 months |

| Lead time | 1 – 2 working days (typical) |

| Terms of payment | T/T and Western Union |

| Courier partners | DHL, UPS, TNT, FedEx and EMS |

GE IS230TNDSH2A

Product Introduction

The GE IS230TNDSH2A is a sophisticated terminal board that holds a prominent place within the General Electric Speedtronic Mark VIe gas turbine control ecosystem. Engineered with precision, this board acts as a crucial linchpin for establishing connections and managing signals in complex industrial control setups. It serves as the vital link between different components of the control system, ensuring seamless communication and accurate data transfer, which are essential for the reliable operation of industrial processes.

Core Advantages and Technical Highlights

Abundant Input and Output Capabilities: Equipped with 24 input channels and 12 relay channels, the IS230TNDSH2A offers extensive capacity for interfacing with a wide array of sensors and actuators. The 24 input channels can efficiently receive signals from various sources such as proximity sensors, limit switches, and temperature sensors. For example, in an industrial manufacturing plant, these inputs can be used to monitor the position of moving parts on a production line. The 12 relay channels, on the other hand, are powerful enough to control high – load devices like motor starters, solenoid valves, and large – scale relays. In a power generation facility, they can be used to switch on or off heavy – duty equipment involved in the power generation process.

Stable Power Handling: With a trip solenoid rating of 125 V DC and a power supply voltage of 28 V DC (operating within a voltage range of 18 – 32 VDC), the board is designed to handle power – intensive applications. This stable power handling capability makes it suitable for use in industrial environments where electrical fluctuations are common. In an oil refinery, for instance, the IS230TNDSH2A can operate under the challenging electrical conditions present, ensuring the consistent operation of equipment such as pumps and compressors.

Optimal Mounting and Compact Design: The DIN – rail mounting design of the IS230TNDSH2A simplifies installation. It can be easily snapped onto a standard DIN rail, which is a common feature in many industrial control cabinets. This not only saves installation time but also ensures a secure and organized mounting. Its compact size of 168 x 150 x 55 mm makes it highly space – efficient, allowing it to fit into cabinets with limited space. In a compact control room where space is at a premium, this board can be installed without taking up excessive room, optimizing the overall layout of the control system.

Reliable Signal Conditioning: The board features advanced signal conditioning technology. The contact input function and onboard signal conditioning are scaled for different wetting voltages (24, 48, and 125 V DC), with input wetness voltage ranges of 16 to 32 V DC, 32 to 64 V DC, and 100 to 145 V DC respectively. This ensures that the incoming signals are accurately processed and transmitted, even in the presence of electrical noise. The noise suppression on the contact inputs guards against surges and high – frequency noise, which is crucial in industrial settings filled with electromagnetic interference. In a metal – working factory, for example, where there are numerous high – power machines generating electrical noise, the IS230TNDSH2A can still accurately receive and process signals from sensors, maintaining the integrity of the control system.

Typical Application Scenarios

Gas Turbine Control Systems: In gas turbine power plants, the IS230TNDSH2A plays a pivotal role. It can connect sensors that monitor critical parameters such as turbine temperature, pressure, and rotational speed to the main control system. At the same time, it can transmit control signals from the control system to actuators that adjust the fuel supply, inlet guide vanes, and other components. By ensuring precise signal transfer, it helps maintain the optimal performance and efficiency of the gas turbine. For example, it can receive signals from temperature sensors in the combustion chamber and transmit control signals to adjust the fuel valves, ensuring efficient combustion and power output.

Industrial Automation in Manufacturing: In manufacturing facilities, this terminal board is used to integrate various automation components. It can connect digital sensors on the production line, such as photoelectric sensors that detect the presence of products, to the programmable logic controller (PLC). It also controls actuators like robotic arms, conveyor belts, and packaging machinery. In an automotive assembly line, the IS230TNDSH2A can be used to coordinate the movement of parts, ensuring that each component is accurately positioned for assembly. It can receive signals from sensors that detect the position of car bodies on the conveyor and transmit control signals to robotic arms to perform welding, painting, and other tasks.

Power Distribution and Monitoring: In power distribution networks, the IS230TNDSH2A is used to control and monitor electrical equipment. It can connect sensors that measure voltage, current, and power quality to the control system. Based on the received data, it can transmit control signals to circuit breakers, switches, and other power – related devices. This helps in maintaining the stability and reliability of the power grid. In a substation, for example, the board can receive signals from current transformers and voltage sensors and transmit control signals to circuit breakers to protect the grid from over – current and other faults.

GE IS230TNDSH2A

Related Model Recommendations

GE IS220PDIOH1A: This discrete I/O pack can be used in conjunction with the IS230TNDSH2A. The IS220PDIOH1A focuses on handling discrete input and output functions, while the IS230TNDSH2A provides the connection and signal management capabilities. In an industrial control system, the IS220PDIOH1A can receive digital input signals from sensors and send control signals to actuators, with the IS230TNDSH2A ensuring seamless communication between the two components and the rest of the control system. Together, they form a comprehensive discrete I/O solution for industrial applications.

GE IS200TBAIH2C: The IS200TBAIH2C is an analog input terminal board. In complex industrial control applications that require both analog and digital signal handling, the IS230TNDSH2A can work in tandem with the IS200TBAIH2C. The IS230TNDSH2A manages digital input and output signals, while the IS200TBAIH2C can handle analog input signals from sensors such as pressure transducers and flow meters. In a chemical plant control system, the IS200TBAIH2C can receive analog signals from sensors that measure chemical concentrations, and the IS230TNDSH2A can control digital actuators based on the processed data from both analog and digital inputs.

GE IS200TBCIH2CAA: This DCS (Distributed Control System) PLC (Programmable Logic Controller) module can communicate effectively with the IS230TNDSH2A. The IS200TBCIH2CAA performs control logic and data processing functions, and the IS230TNDSH2A provides the interface for connecting input and output devices to the IS200TBCIH2CAA. In an industrial automation system, the IS200TBCIH2CAA can send control commands to the IS230TNDSH2A, which then transmits the signals to the appropriate actuators. It can also receive feedback signals from sensors through the IS230TNDSH2A for further processing, enabling efficient control of industrial processes.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the IS230TNDSH2A, turn off the power to the control system to prevent electrical accidents. Use anti – static precautions, such as wearing an anti – static wristband, to protect the board from electrostatic discharge (ESD) damage. Check that the DIN – rail in the installation location is in good condition and compatible with the board’s mounting design. Verify that the connectors on the board and the mating connectors in the control system are clean and free of debris. Ensure that the power supply in the system can provide the required 28 V DC within the specified voltage range of 18 – 32 VDC.

Commissioning: After installation, power on the system. Use the appropriate software or control interface to configure the board’s settings, such as input/output signal mapping and communication protocols. Test each input and output channel by connecting known sensors and actuators. For the 24 input channels, connect sensors like proximity switches and verify that the board correctly detects their status. For the 12 relay channels, connect actuators such as solenoid valves and check that they respond as expected to control signals. Check for any error messages or abnormal behavior during the testing phase. Monitor the communication between the board and other components in the control system to ensure seamless data transfer.

Maintenance Suggestions: Regularly perform visual inspections of the IS230TNDSH2A for any signs of physical damage, such as bent pins, cracks in the circuit board, or discolored components. Check for loose connections on the connectors, as loose connections can lead to signal loss or intermittent operation. Monitor the operating temperature and humidity of the environment where the board is installed, ensuring they remain within the specified ranges of 40 to 70 °C for temperature. If any input or output channels fail to operate correctly, use diagnostic tools to check for electrical faults, such as short – circuits or open – circuits. Replace the board if any irreparable damage is detected. Follow GE’s recommended maintenance schedule and procedures for optimal performance. Given its 12 – month warranty, contact GE’s customer service for any warranty – related issues.

Service and Guarantee Commitment

GE offers a 12 – month warranty for the IS230TNDSH2A, which covers manufacturing defects and component failures under normal operating conditions. Technical support is readily available through GE’s customer service channels. Trained technicians can assist with installation, troubleshooting, and any other technical issues related to the board. Customers can access comprehensive product documentation, including installation manuals, technical specifications, and maintenance guides, through GE’s official website. In the event of a warranty claim, GE will work promptly to provide a resolution, either through repair or replacement of the faulty board, aiming to minimize downtime for the customer’s operations.