Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

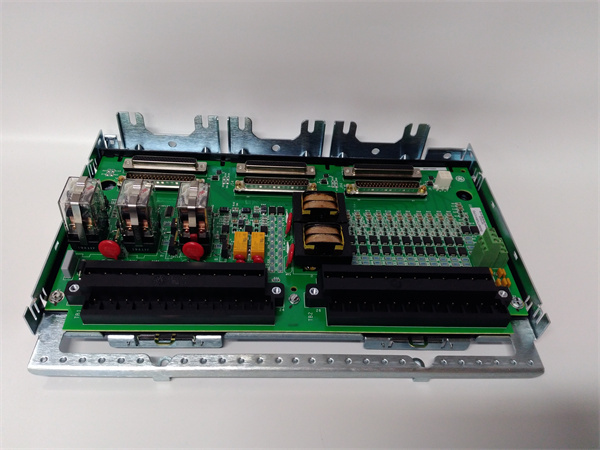

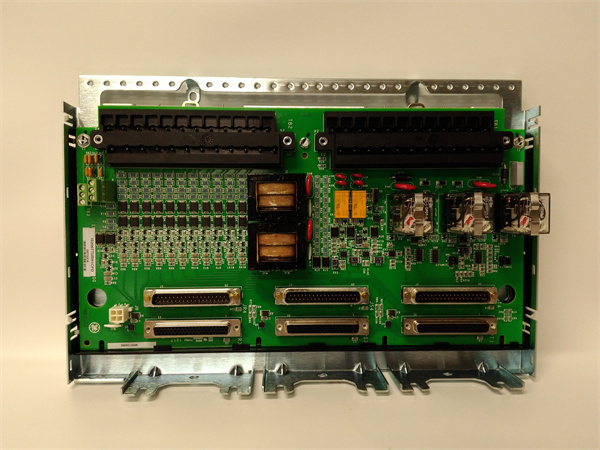

| Product model | **GE IS230TNTRHIC** |

| Manufacturer | General Electric (GE) |

| Product category | Isolated Digital Input DIN Rail Module |

| Series | Mark VIe |

| Number of digital inputs | 16 channels |

| Input signal type | Dry contact / Wet contact (24V DC) |

| Input voltage range | 18V DC – 30V DC |

| Isolation type | Channel – to – channel optical isolation |

| Operating temperature range | -40°C to +70°C |

| Response time | ≤1ms (typical) |

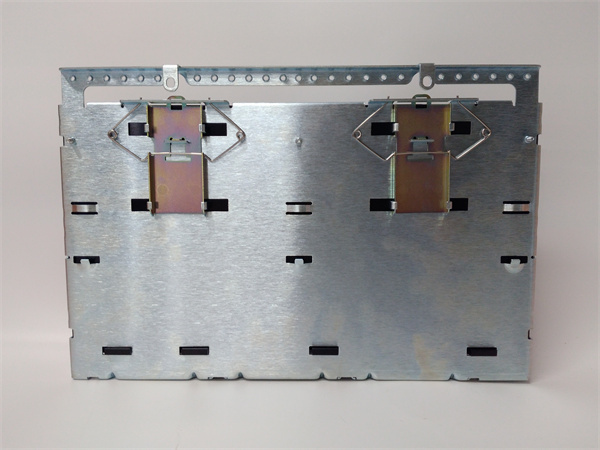

| Installation method | DIN rail mounting (35mm standard) |

| Safety certification | IEC 61508 SIL 2, CE, UL 508 |

| Physical size | 17.8 cm (W) × 33.0 cm (H) × 12.7 cm (D) |

GE IS230TNTRHIC

Product Introduction

The **GE IS230TNTRHIC** is a high – performance isolated digital input DIN rail module under GE’s Mark VIe control system series, specifically designed for accurate collection and reliable transmission of digital signals in industrial automation environments. As a critical front – end data acquisition component, it serves as the link between field sensors (such as limit switches, proximity sensors, and pushbuttons) and the upper – level controller, converting on – site discrete status signals into digital data that the control system can process.

In complex industrial control loops, the **GE IS230TNTRHIC** excels in capturing real – time status information of field devices. Its advanced isolation technology and anti – interference design ensure that the collected signals remain accurate even in harsh environments with strong electromagnetic interference, voltage fluctuations, and temperature variations. By providing high – quality digital input data, the **GE IS230TNTRHIC** lays a solid foundation for the controller to make accurate control decisions, thereby enhancing the overall stability and responsiveness of the automation system.

Core advantages and technical highlights

Channel – to – Channel Isolation: Each of the 16 input channels of the **GE IS230TNTRHIC** is equipped with independent optical isolation, which effectively prevents signal crosstalk between channels and protects the module from damage caused by high – voltage transients or ground loops. This isolation design not only improves the reliability of signal acquisition but also enhances the safety of the entire control system, making it suitable for applications in high – voltage industrial environments such as power plants and smelting facilities.

Fast Response and High Accuracy: With a typical response time of ≤1ms, the **GE IS230TNTRHIC** can quickly capture changes in field device status, ensuring that the control system can respond in a timely manner to dynamic process changes. The module’s internal signal conditioning circuit filters out high – frequency noise and false signals, ensuring that the transmitted digital data accurately reflects the actual status of the field devices. This level of responsiveness and accuracy is crucial for time – critical control applications such as emergency shutdown systems and precision manufacturing processes.

Flexible Signal Compatibility: The **GE IS230TNTRHIC** supports both dry contact and wet contact input signals, with an input voltage range of 18V DC – 30V DC. This flexibility allows it to be compatible with a wide range of field sensors and switches, eliminating the need for additional signal conversion devices. The module also features configurable input filtering time (0.1ms – 100ms) via software, enabling users to adjust the filtering level according to different application scenarios to further improve signal quality.

Seamless Mark VIe Integration: As an integral part of the Mark VIe ecosystem, the **GE IS230TNTRHIC** seamlessly connects to GE’s Mark VIe controllers and other I/O modules through the system backplane. It supports automatic module recognition and configuration by the controller, reducing the complexity of system commissioning. The compact DIN rail mounting design saves valuable space in control cabinets, and the hot – swappable capability (when used with compatible racks) allows for module replacement without interrupting the entire system operation, improving the system’s availability.

Typical application scenarios

In power generation plants, the **GE IS230TNTRHIC** is widely used in turbine control systems to collect status signals from turbine valves, bearings, and cooling systems. For example, it monitors the open/close status of fuel control valves and the trip status of emergency shutdown devices, transmitting these signals to the Mark VIe controller in real – time. The controller then uses this information to adjust the turbine’s operating parameters or trigger emergency shutdown procedures when necessary, ensuring the safe and efficient operation of the turbine.

In oil and gas production facilities, the **GE IS230TNTRHIC** is deployed in wellhead control systems to capture status signals from wellhead valves, pressure relief devices, and pipeline blockage detectors. It also plays a key role in offshore platforms, where it collects data from marine – grade sensors to monitor the status of drilling equipment and safety systems. In manufacturing automation lines, the module is used to track the position of conveyor belts, the status of robotic arms, and the presence of workpieces, enabling synchronized and efficient production operations. Additionally, it is applied in water treatment plants to monitor the status of pumps, valves, and filter systems, ensuring the stable operation of the water treatment process.

Related model recommendations

**GE IS230TRLYH1B**: A digital relay output module from the same Mark VIe series, which receives control commands from the controller and executes switching actions, forming a complete input – output control loop with the **GE IS230TNTRHIC**.

**GE IS230TSPRH1CDIN**: A signal processing module that processes analog input signals and works with the **GE IS230TNTRHIC** to provide comprehensive data acquisition capabilities for the control system.

**GE IS230TDBTH6A**: A discrete I/O terminal board that provides additional wiring terminals for the **GE IS230TNTRHIC**, simplifying field wiring and facilitating maintenance.

**GE IS230TNTRH2C**: An upgraded version of the **GE IS230TNTRHIC** with 32 digital input channels, suitable for applications requiring a larger number of input points.

**GE IS230TCICH1A**: A communication interface module that extends the connectivity of the **GE IS230TNTRHIC** to Ethernet/IP networks, enabling remote monitoring and data transmission.

**GE IS230SNIDH1A**: Another isolated digital input module with different input voltage specifications, which can be used in parallel with the **GE IS230TNTRHIC** to meet diverse field signal requirements.

**GE IS230SNRTH2A**: A variable frequency drive module that, when paired with the **GE IS230TNTRHIC**, enables speed control of AC motors based on the collected status signals.

GE IS230TNTRHIC

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the **GE IS230TNTRHIC**, ensure the control cabinet is clean, dry, and free from corrosive gases and dust. The ambient temperature should be within -40°C to +70°C, and the relative humidity should not exceed 95% (non – condensing). Required tools include a 35mm DIN rail cutter, Phillips screwdriver, wire stripper, and multimeter. Disconnect the power supply of the control system before installation. Align the module with the DIN rail, push it firmly until it locks into place, and secure it with side locking screws to prevent displacement due to vibration. Use twisted – pair shielded cables for wiring, and connect the cable shield to the cabinet ground to reduce electromagnetic interference.

Maintenance suggestions: Conduct monthly visual inspections of the **GE IS230TNTRHIC** to check for loose wiring, damaged LED status indicators, or abnormal module heating. Clean the module surface and ventilation holes quarterly using compressed air with a pressure not exceeding 0.5MPa to remove dust accumulation. Test the input channels annually using a signal generator to verify their responsiveness and accuracy; if a channel fails to respond or transmits incorrect signals, check the wiring and isolation circuit, and replace the module if necessary. Always use genuine GE spare parts for replacements to ensure compatibility and performance. During maintenance, strictly follow the safety procedures outlined in the Mark VIe system manual to avoid electrical hazards.

Service and guarantee commitment

The **GE IS230TNTRHIC** comes with a 12 – month manufacturer’s warranty covering defects in materials and workmanship. GE’s global technical support team provides 24/7 assistance via email, online portals, and phone, offering prompt troubleshooting guidance, technical documentation, and software updates. For on – site service needs, GE’s certified engineers can be dispatched to customer locations within 48 hours in major industrial regions. We also offer extended warranty plans up to 3 years and customized preventive maintenance services to maximize the operational lifespan and reliability of the **GE IS230TNTRHIC**. GE is committed to delivering high – quality products and professional services, ensuring that customers receive consistent support throughout the product’s lifecycle.