Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

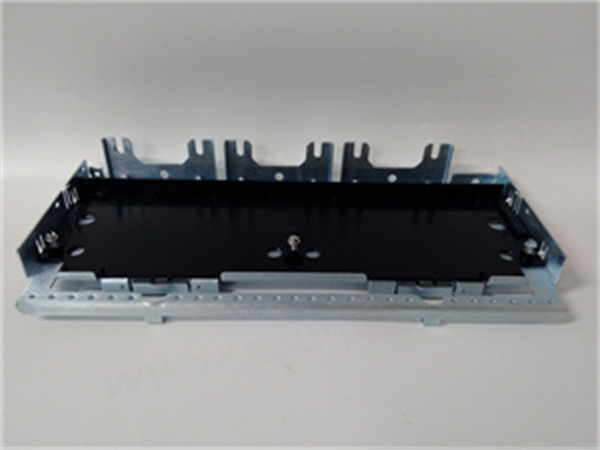

| Product model | **GE IS230TRLYH1B** |

| Manufacturer | General Electric (GE) |

| Product category | Digital Relay Output DIN Rail Module |

| Series | Mark VIe |

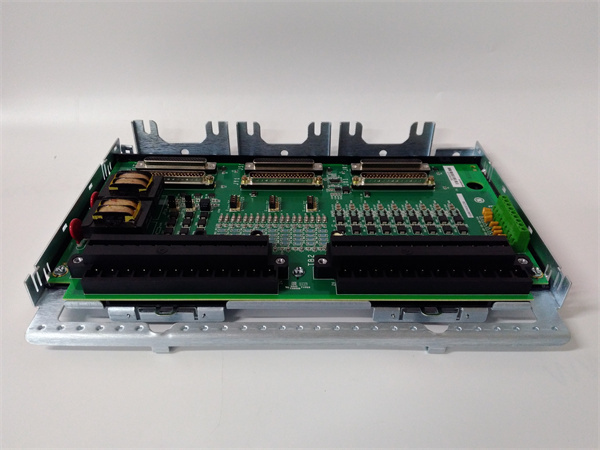

| Number of relay outputs | 8 channels |

| Relay type | Electromechanical relay |

| Rated voltage | 250V AC / 30V DC |

| Rated current | 5A per channel |

| Operating temperature range | -40°C to +70°C |

| Isolation type | Optical isolation (input – output) |

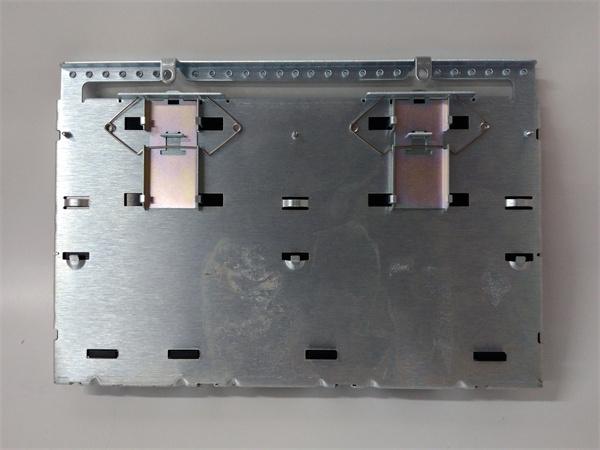

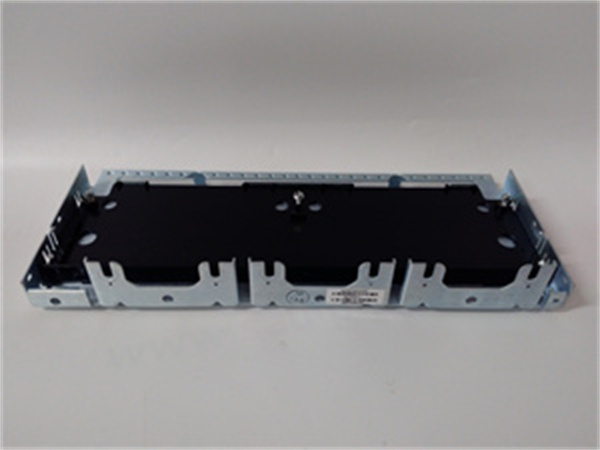

| Installation method | DIN rail mounting (35mm standard) |

| Safety certification | IEC 61508 SIL 2, UL 508 |

| Physical size | 17.8 cm (W) × 33.0 cm (H) × 12.7 cm (D) |

GE IS230TRLYH1B

Product Introduction

The **GE IS230TRLYH1B** is a high – reliability digital relay output DIN rail module under GE’s flagship Mark VIe control system series, specifically designed for translating low – level control signals into high – power switching actions in industrial automation. As a key execution component in distributed control architectures, it serves as the bridge between the upper – level controller and field actuators, enabling precise and timely control of external equipment such as valves, motors, and alarms.

In critical industrial processes, the **GE IS230TRLYH1B** excels in converting digital control commands from the Mark VIe system into mechanical relay closures or openings. Its robust design ensures stable operation even in harsh environments with electrical noise, vibration, and temperature fluctuations. By providing reliable switching capabilities, the **GE IS230TRLYH1B** not only guarantees the smooth execution of control strategies but also enhances the overall safety and efficiency of the automation system.

Core advantages and technical highlights

Robust Relay Performance: Each of the 8 channels in the **GE IS230TRLYH1B** is equipped with high – quality electromechanical relays that offer a rated current of 5A and support both AC and DC loads. The relays feature a long mechanical life of over 10 million operations and an electrical life of 100,000 operations at full load, ensuring long – term reliability in high – duty – cycle applications. This durability minimizes the need for frequent replacements, reducing maintenance costs and downtime.

Flexible Configuration: The **GE IS230TRLYH1B** supports configurable relay contact modes, allowing each channel to be set as normally open (NO) or normally closed (NC) via front – panel jumpers. This flexibility enables the module to adapt to various control logic requirements without the need for additional wiring or external components. Additionally, the module provides LED status indicators for each channel, offering real – time visual feedback on the relay state for easy monitoring and troubleshooting.

Enhanced Safety and Isolation: With optical isolation between the input control circuit and output relay circuit, the **GE IS230TRLYH1B** effectively prevents high – voltage transients and electrical noise from interfering with the control system. It complies with IEC 61508 SIL 2 safety standards, making it suitable for safety – related applications in power generation, oil and gas, and chemical industries. The module also features surge protection on the output terminals, safeguarding against voltage spikes caused by inductive load switching.

Seamless System Integration: Designed as part of the Mark VIe ecosystem, the **GE IS230TRLYH1B** seamlessly integrates with GE’s controllers, I/O modules, and communication interfaces. It communicates with the system via the Mark VIe backplane, ensuring fast and reliable data exchange with a response time of less than 1ms. The DIN rail mounting design saves space in control cabinets, and the hot – swappable capability (when used with compatible racks) allows for module replacement without shutting down the entire system, improving operational availability.

Typical application scenarios

In power generation plants, the **GE IS230TRLYH1B** is widely used in turbine control systems to actuate fuel control valves, lubrication pumps, and emergency shutdown devices. When the Mark VIe controller issues a command to adjust turbine load, the **GE IS230TRLYH1B** switches the corresponding relays to control the opening or closing of valves, ensuring precise fuel supply and stable turbine operation. Its ability to withstand high temperatures and vibration makes it ideal for installation in turbine enclosures.

In oil and gas production facilities, the **GE IS230TRLYH1B** drives pipeline valves, pump stations, and pressure relief devices. For example, in wellhead control applications, it receives signals from the SCADA system to switch relays that operate downhole valves, regulating the flow of oil or gas. In chemical processing plants, the module controls the operation of agitators, heating elements, and safety alarms, ensuring that process parameters stay within the specified range and triggering alarms in case of abnormalities. Additionally, it is used in manufacturing automation lines to control conveyor belts, robotic arms, and packaging equipment, enabling synchronized production processes.

Related model recommendations

**GE IS230TSPRH1CDIN**: A signal processing module from the same Mark VIe series, which processes analog input signals and sends control commands to the **GE IS230TRLYH1B** for execution.

**GE IS230SNIDH1A**: An isolated digital input module that collects digital signals from sensors and transmits them to the controller, working with the **GE IS230TRLYH1B** to form a complete input – output control loop.

**GE IS230TDBTH6A**: A discrete I/O terminal board that provides additional wiring terminals for the **GE IS230TRLYH1B**, simplifying field wiring and improving maintenance efficiency.

**GE IS230TRLYH2B**: An upgraded version of the **GE IS230TRLYH1B** with 16 relay outputs, suitable for applications requiring more channels.

**GE IS230TCICH1A**: A communication interface module that extends the connectivity of the **GE IS230TRLYH1B** to Ethernet/IP networks, facilitating remote monitoring and control.

**GE IS230SNRTH2A**: A variable frequency drive module that, when paired with the **GE IS230TRLYH1B**, enables speed control of AC motors in fan and pump applications.

**GE IS230TNRLH1B**: A latching relay module that complements the **GE IS230TRLYH1B** in applications requiring maintaining relay state without continuous power.

GE IS230TRLYH1B

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the **GE IS230TRLYH1B**, ensure the control cabinet is clean, dry, and free from corrosive gases. The ambient temperature should be within -40°C to +70°C, and relative humidity below 95% (non – condensing). Required tools include a 35mm DIN rail cutter, Phillips screwdriver, wire crimping tool, and multimeter. Disconnect the power supply of the control system before installation. Align the module with the DIN rail, push it firmly until it locks into place, and secure it with the side locking screws to prevent displacement due to vibration. Use twisted – pair shielded cables for wiring, and connect the shield to the cabinet ground to reduce electromagnetic interference.

Maintenance suggestions: Conduct monthly inspections of the **GE IS230TRLYH1B** to check for loose wiring, damaged LED indicators, or relay sticking. Clean the module surface and ventilation holes quarterly using compressed air with a pressure not exceeding 0.5MPa to remove dust. Test the relay contacts annually using a multimeter to measure contact resistance; if the resistance exceeds 100mΩ, replace the relay module. In case of relay failure, use genuine GE replacement relays to ensure compatibility and performance. Avoid hot – swapping the module unless the system supports it, and always follow the safety procedures in the Mark VIe system manual during maintenance.

Service and guarantee commitment

The **GE IS230TRLYH1B** comes with a 12 – month manufacturer’s warranty covering defects in materials and workmanship. GE’s global technical support team provides 24/7 assistance through email and online portals, offering prompt troubleshooting guidance and technical documentation. For on – site service needs, GE’s certified engineers can be dispatched to customer locations within 48 hours in major industrial areas. We also offer extended warranty plans up to 3 years and customized preventive maintenance services to maximize the operational lifespan of the **GE IS230TRLYH1B**. GE is committed to delivering reliable products and professional services, ensuring that customers receive consistent performance and support throughout the product’s lifecycle.