Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

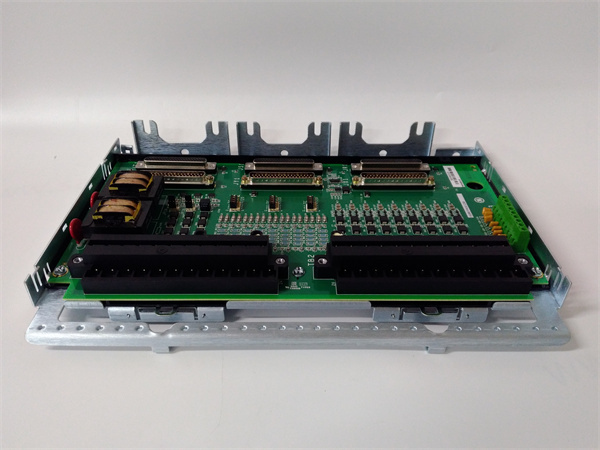

| Product model | **GE IS230TSPRH1CDIN** |

| Manufacturer | General Electric (GE) |

| Product category | Signal Processing DIN Rail Module |

| Series | Mark VIe |

| Communication protocol | Tricon Communication Module (TCM) |

| Operating temperature range | -40°C to +70°C |

| Isolation type | Optical isolation |

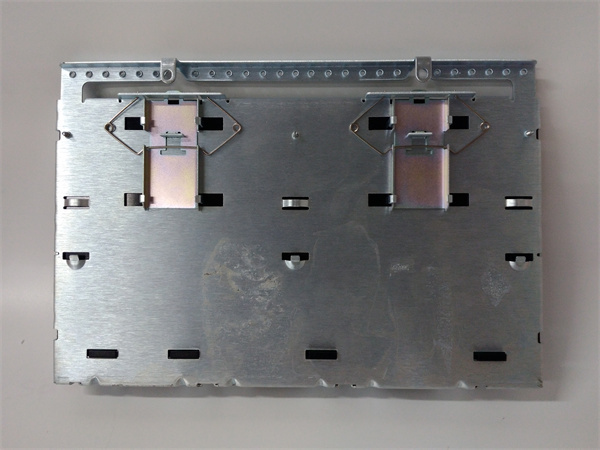

| Installation method | DIN rail mounting |

| Safety certification | IEC 61508 SIL 2/SIL 3 compliant |

| Physical size | 17.8 cm (W) × 33.02 cm (H) |

| Input signal type | Discrete analog input (4-20mA) |

| Voltage rating | 24V DC (power supply) |

GE IS230TSPRH1CDIN

Product Introduction

The **GE IS230TSPRH1CDIN** is a high-performance signal processing DIN rail module belonging to GE’s renowned Mark VIe control system series, specifically engineered for critical industrial automation applications. As a core component in distributed control architectures, it specializes in precise conditioning, isolation, and processing of analog input signals, ensuring reliable data transmission between field devices and upper-level control systems. Its design is tailored to meet the stringent requirements of industries where signal integrity and system stability are paramount.

In turbine control systems and process automation setups, the **GE IS230TSPRH1CDIN** plays a pivotal role in converting raw sensor data into actionable control signals. By integrating advanced signal filtering and isolation technologies, it effectively mitigates the impact of electrical noise, voltage spikes, and ground loops—common challenges in harsh industrial environments. This module not only enhances the overall accuracy of control systems but also extends the lifespan of connected equipment by providing robust electrical protection.

Core advantages and technical highlights

Safety and Reliability: The **GE IS230TSPRH1CDIN** adheres to IEC 61508 SIL 2/SIL 3 safety standards, making it suitable for safety-critical applications in power generation, oil, and gas sectors. Its redundant design elements and fault-detection mechanisms minimize the risk of unexpected failures, ensuring continuous operation even in demanding conditions. The optical isolation between input and output circuits further enhances safety by preventing cross-circuit contamination and protecting sensitive control components.

Signal Processing Precision: Equipped with high-resolution analog-to-digital converters (ADCs), the **GE IS230TSPRH1CDIN** delivers exceptional signal accuracy with a sampling rate of up to 1kHz. Its advanced noise suppression algorithms filter out high-frequency interference and transient signals, ensuring that the processed data accurately reflects real-time field conditions. This level of precision is crucial for optimizing turbine performance, maintaining process parameters within tight tolerances, and enabling predictive maintenance strategies.

Easy Integration and Space Efficiency: Designed for DIN rail mounting, the **GE IS230TSPRH1CDIN** features a compact form factor that maximizes space utilization in control cabinets. It seamlessly integrates with GE’s Mark VIe system ecosystem and supports communication via the Tricon Communication Module (TCM), enabling plug-and-play connectivity with other system components. The module’s front-panel test points and configuration jumpers simplify commissioning and troubleshooting, reducing downtime during installation and maintenance.

Typical application scenarios

In gas turbine control systems, the **GE IS230TSPRH1CDIN** is used to process signals from temperature, pressure, and vibration sensors, providing the control unit with accurate data to adjust fuel flow, turbine speed, and cooling systems. Its ability to withstand extreme temperatures and vibration ensures reliable operation in turbine enclosures, where environmental conditions are often harsh. In steam turbine applications, it plays a key role in monitoring boiler feedwater parameters and regulating turbine load, contributing to efficient power generation.

The **GE IS230TSPRH1CDIN** is also widely deployed in power plants for monitoring auxiliary equipment such as pumps, fans, and valves. In oil and gas production facilities, it processes signals from flow meters, level sensors, and pressure transducers in wellheads and pipelines, enabling precise control of extraction and transportation processes. Additionally, it finds applications in industrial automation lines where analog signal processing is required for quality control, process optimization, and equipment health monitoring.

Related model recommendations

**GE IS230TNRLH1B**: A digital output relay module from the same Mark VIe series, used to convert control signals into relay outputs for driving actuators and valves, perfectly matching the signal processing capabilities of the **GE IS230TSPRH1CDIN**.

**GE IS230TDBTH6A**: A discrete I/O terminal board that expands the input/output capacity of the Mark VIe system, providing additional connection points for field devices when used with the **GE IS230TSPRH1CDIN**.

**GE IS230SNIDH1A**: An isolated digital input module that complements the **GE IS230TSPRH1CDIN** by processing digital signals from limit switches and proximity sensors in industrial environments.

**GE IS230SNRTH2A**: A variable frequency drive module for AC motors, working in tandem with the **GE IS230TSPRH1CDIN** to regulate motor speed based on processed analog signals in fan and pump control applications.

**GE IS230TSPRH2CDIN**: The upgraded version of the **GE IS230TSPRH1CDIN**, featuring higher sampling rates and enhanced communication capabilities for more demanding signal processing tasks.

**GE IS230TCICH1A**: A communication interface module that extends the **GE IS230TSPRH1CDIN**’s connectivity options to support Ethernet/IP protocols, facilitating integration with modern industrial networks.

GE IS230TSPRH1CDIN

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the **GE IS230TSPRH1CDIN**, ensure the control cabinet environment is free from excessive dust, moisture, and corrosive gases. The ambient temperature should be within -40°C to +70°C, and relative humidity below 95% (non-condensing). Required tools include a Phillips screwdriver, wire stripper, and multimeter. Ensure the power supply is disconnected before wiring, and use shielded cables for input signals to minimize electromagnetic interference. Align the module with the DIN rail and push until it clicks into place, then secure it with the locking clip to prevent vibration-induced displacement.

Maintenance suggestions: Conduct monthly visual inspections of the **GE IS230TSPRH1CDIN** to check for loose terminals, damaged cables, or indicator light abnormalities. Clean the module’s surface and ventilation slots quarterly using compressed air to remove dust buildup. Calibrate the signal processing circuit annually using a standard signal generator to maintain accuracy. In case of faults, use the front-panel test points to isolate issues—common problems include blown fuses (replace with 5A slow-blow fuses) and faulty input circuits (check for short circuits or sensor malfunctions). Always use genuine GE spare parts for replacements to ensure compatibility and safety.

Service and guarantee commitment

The **GE IS230TSPRH1CDIN** comes with a 12-month manufacturer’s warranty covering defects in materials and workmanship. GE’s global technical support team provides 24/7 assistance via phone and email, offering prompt troubleshooting guidance and commissioning support. For on-site service needs, GE’s network of certified engineers can be dispatched to customer locations within 48 hours in major industrial regions. Additionally, GE offers extended warranty plans and preventive maintenance contracts to maximize the module’s operational lifespan. We stand behind the quality of the **GE IS230TSPRH1CDIN** and are committed to ensuring customer satisfaction through reliable products and professional after-sales service.