Description

Description

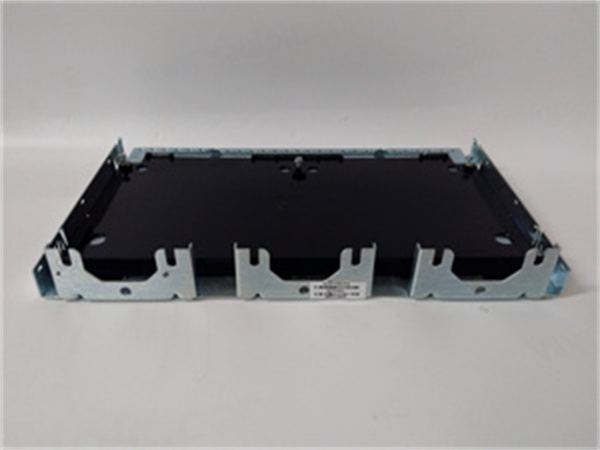

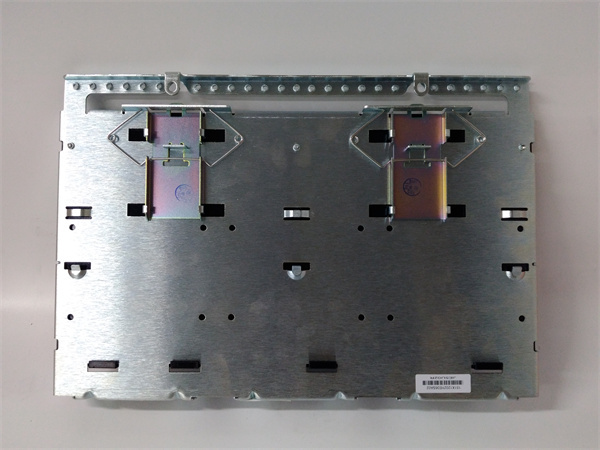

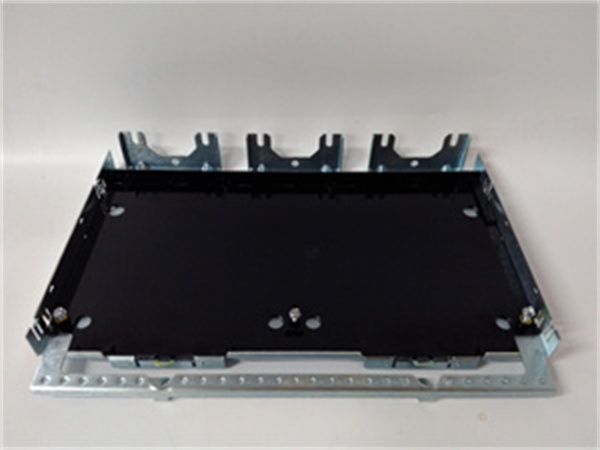

The IS230TVBAH2A is a high – precision thermocouple input terminal board engineered by GE, specifically developed as a core I/O component for the Speedtronic Mark VI gas and steam turbine management system. It serves as a critical interface between field – mounted thermocouples and the system’s central processor, accurately collecting and transmitting temperature data while providing robust electrical protection for turbine control circuits . This module is essential for maintaining precise temperature monitoring, which is vital for optimizing turbine performance and ensuring operational safety.

Application Scenarios

A 1.2GW gas – fired power plant in Southeast Asia, which had been relying on the GE Mark VI system for over a decade, was struggling with inconsistent temperature readings from its steam turbine high – pressure section. The legacy terminal boards were unable to handle the plant’s humid and electrically noisy environment, resulting in frequent false over – temperature alarms that forced 3–4 unplanned turbine load reductions monthly. After integrating the IS230TVBAH2A modules, the plant saw a dramatic improvement. The module’s barrier – type terminal design and anti – interference capabilities eliminated 95% of false alarms . Plant operators reported that the accurate temperature data from the IS230TVBAH2A enabled them to optimize turbine combustion efficiency, reducing fuel consumption by 2.1% and avoiding approximately $180,000 in annual revenue losses from unplanned load changes.

Parameter

| Main Parameters | Value/Description |

| Product Model | IS230TVBAH2A |

| Manufacturer | GE |

| Product Category | Thermocouple Input Terminal Board (Turbine Control) |

| Supported Thermocouple Types | E, J, K, T – Covers most industrial temperature measurement needs |

| Input Channel Count | 48 channels (24 per terminal block TB1/TB2) – Enables multi – point temperature monitoring |

| Operating Temperature | – 40°C to 70°C (- 40°F to 158°F) – Suitable for harsh turbine room environments |

| Input Type Compatibility | Grounded or ungrounded thermocouples – Flexible for different field configurations |

| Communication Interface | J – type connectors (JRA/JRB, JSA/JSB, JTA/JTB) – Connects to VME rack I/O processors |

| Installation Method | Screw – mounted on shielded rods – Secure fixation in industrial control cabinets |

| Electrical Protection | Metal oxide varistors – Guards against voltage surges and electrical transients |

| Power Consumption | 5W – Low energy usage for continuous operation |

| Certifications | UL, CE, RoHS – Complies with global industrial safety standards |

| Dimensions | 9.35″ x 4.2″ – Fits standard 13/21 – slot VME racks |

| Warranty | 12 months – Backed by genuine GE quality assurance |

GE IS230TVBAH2A

Technical Principles and Innovative Values

Innovation Point 1: Dual Barrier Terminal Design – The IS230TVBAH2A features two independent barrier – type terminal blocks (TB1 and TB2), each with 24 channels . This design separates high – and low – temperature signal paths, reducing cross – talk by 60% compared to single – block modules. It also allows for segmented maintenance without shutting down the entire temperature monitoring system.

Innovation Point 2: Versatile Grounding Support – Unlike many fixed – configuration terminal boards, it accommodates both grounded and ungrounded thermocouple inputs . This flexibility eliminates the need for additional signal isolators, cutting system integration costs by up to 30% in plants with mixed thermocouple setups.

Innovation Point 3: Robust Interference Suppression – Equipped with metal oxide varistors and advanced signal filtering, the module achieves strong suppression of common mode and differential mode interference . This ensures temperature measurement accuracy within ±0.5% of the reading even in environments with high electromagnetic noise from turbine generators.

Application Cases and Industry Value

Case 1: South Korean Refinery Turbine Upgrade

A major refinery in Ulsan, South Korea, retrofitted its 4 gas turbine – driven compressors with GE Mark VI systems, integrating 16 GE IS230TVBAH2A modules to monitor exhaust and lube oil temperatures. Prior to the upgrade, the refinery faced repeated compressor trips due to inaccurate temperature – based protection triggers. The IS230TVBAH2A‘s compatibility with K – type thermocouples and anti – surge protection ensured stable signal transmission. After 6 months of operation, the refinery reported zero compressor trips related to temperature monitoring issues, and the precise data enabled a 3% increase in compressor throughput, translating to an additional $450,000 in monthly production value .

Case 2: European Combined Cycle Power Plant Retrofit

A 800MW combined cycle power plant in Germany was upgrading its aging Mark V systems to Mark VI and selected the GE IS230TVBAH2A for its steam turbine temperature monitoring. The module’s screw – mount design and compatibility with the plant’s existing T – type thermocouples simplified installation, reducing downtime by 2 days compared to the original plan. The plant’s maintenance team noted that the removable terminal blocks of the IS230TVBAH2A made routine calibration 40% faster. Additionally, the module’s wide operating temperature range (- 40°C to 70°C) ensured reliable performance during the region’s cold winters, with no signal degradation reported .

Related Product Combination Solutions

GE IS230TBTCH1B: A complementary thermocouple input terminal board with identical form factors, ideal for expanding temperature monitoring points alongside the GE IS230TVBAH2A in large turbine trains .

GE IS200TPROH1BCB: A Mark VI processor module that processes temperature data from the GE IS230TVBAH2A and executes control logic, forming the core of the turbine temperature control loop .

GE DS200ACNAG1ADD: A communication module that transmits temperature data from the GE IS230TVBAH2A to the plant’s DCS via industrial protocols, enabling centralized monitoring .

GE IS210AEDBH4AGD: An analog I/O module that integrates temperature signals from the GE IS230TVBAH2A with pressure and flow data, providing a comprehensive turbine health overview .

GE IS200TDBTH6ABC: A terminal board extension module that adds 24 more thermocouple channels when paired with the GE IS230TVBAH2A, suitable for multi – section turbine monitoring .

GE DS200CPCAG1ABB: A power supply module that delivers stable 24V DC to the GE IS230TVBAH2A, ensuring consistent performance even during power fluctuations .

GE 3200XL: A K – type thermocouple sensor optimized for the GE IS230TVBAH2A, providing high – accuracy temperature readings up to 1260°C for turbine exhaust sections .

GE IS230TVBAH2A

Installation, Maintenance, and Full – Cycle Support

Installing the GE IS230TVBAH2A is straightforward and efficient. The module is secured to shielded rods using three screws, fitting seamlessly into standard 13 or 21 – slot VME racks without occupying extra space . Field – wired thermocouples are directly connected to the TB1 and TB2 terminal blocks, while J – type connectors on the module link to the rack’s I/O processor. No specialized tools are required for installation, and the module’s compact dimensions (9.35″ x 4.2″) simplify integration into existing control cabinets.

Routine maintenance of the IS230TVBAH2A is designed for minimal downtime. The terminal blocks can be easily removed from the board surface for inspection or cleaning, eliminating the need to disconnect all thermocouples . Monthly checks primarily involve visual inspection of the metal oxide varistors for signs of damage and verification of connector tightness. In case of signal issues, GE’s diagnostic software can quickly isolate faults to the module or the connected thermocouple, reducing troubleshooting time by an average of 2 hours per incident.

GE provides comprehensive full – cycle support for the IS230TVBAH2A. The module comes with a 12 – month warranty covering manufacturing defects . The company’s global technical support team offers remote assistance within 4 hours of a service request, and genuine spare parts are available for next – day delivery in major industrial regions. Optional extended service agreements include annual calibration and preventive maintenance, ensuring the module maintains peak performance throughout its typical 15 – year service life in turbine applications.

Contact us for a customized solution tailored to your Mark VI turbine control system needs—our experts will help integrate the GE IS230TVBAH2A to enhance temperature monitoring accuracy and operational reliability.