Description

Professional Product Description: GE IS400JGPAG1A Entry-Level Analog Input Module

Detailed Parameter Table

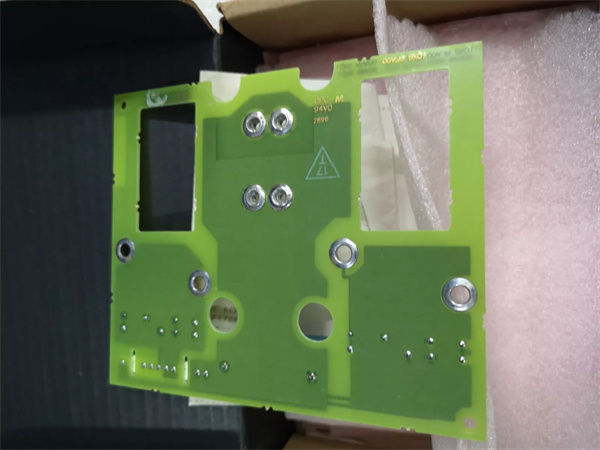

| Parameter Name | Parameter Value |

| Product model | GE IS400JGPAG1A |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Entry-Level Analog Input Module (Legacy GE Control System Compatibility) |

| Input Configuration | 8 analog inputs (4–20mA DC, 0–10V DC); Single-ended, non-isolated |

| Measurement Accuracy | ±0.1% of full scale (25°C); ±0.2% of full scale (-20°C to +60°C) |

| Resolution | 12-bit (4,096 discrete levels) |

| Update Rate | 5ms per input channel (sequential sampling) |

| Communication Interface | Parallel backplane (compatible with GE Mark V/VI systems); No Ethernet support |

| Power Requirements | 24V DC (from control system backplane); Current draw: 0.3A typical, 0.5A peak |

| Physical Dimensions (H×W×D) | 130mm × 95mm × 30mm (slot-mount form factor); Weight: 190g |

| Operating Temperature Range | -20°C to +60°C (ambient); -30°C to +70°C (short-term storage, <72h) |

| Environmental Protection | Basic conformal coating (moisture/dust resistance); IP20 terminal protection |

| Protection Features | Input overvoltage protection (up to 30V DC); Reverse polarity protection |

| Calibration Support | Manual potentiometer calibration (factory-set; field-adjustable via trim pots) |

| Certifications | CE, UL 508C, IEC 61010-1 |

| Compatibility | GE Legacy Control Systems (Mark V, Mark VI); GE DS200CTBAG1A (terminal board); Basic industrial sensors (pressure, level, temperature); Non-critical process monitoring |

GE DS200IQXSG1A

Product introduction

GE IS400JGPAG1A is an entry-level analog input module engineered for GE’s legacy control systems (e.g., Mark V, Mark VI), designed to deliver reliable, cost-effective data acquisition for non-critical industrial processes. Unlike high-performance analog modules (e.g., GE IS410JPDEG1A), GE IS400JGPAG1A prioritizes simplicity and compatibility over advanced features, making it ideal for retrofitting older GE systems or monitoring basic process variables where precision beyond ±0.1% is unnecessary.

In industrial automation, GE IS400JGPAG1A serves as a “bridge” between analog sensors and legacy GE controllers, converting raw sensor signals into digital data the system can process. For example, in a small municipal wastewater treatment plant using a GE Mark VI system, GE IS400JGPAG1A monitors 6 4–20mA level sensors (tracking tank fill levels) and 2 0–10V pressure sensors (monitoring pump discharge pressure). This data helps operators maintain basic process control without the cost of upgrading to a full Mark VIe system.

What defines GE IS400JGPAG1A is its balance of affordability and familiarity: it uses the same slot-mount design as legacy GE modules, requires no specialized software for configuration, and integrates seamlessly with existing Mark V/VI backplanes. This makes it a go-to choice for facilities looking to extend the life of their legacy systems—avoiding the $100k+ cost of a full control system upgrade.

Core advantages and technical highlights

Legacy System Compatibility for Cost-Effective Retrofits: GE IS400JGPAG1A is purpose-built to work with GE’s Mark V/VI systems, eliminating the need for expensive adapters or backplane modifications. In a 1990s-era gas turbine auxiliary control system (Mark V), replacing a failed obsolete analog module with GE IS400JGPAG1A took less than 1 hour—no reconfiguration of the controller was needed. This compatibility saved the plant $50k compared to upgrading to a Mark VIe system, while keeping auxiliary pumps and fans operational.

Simple Operation for Non-Expert Users: Unlike modern modules requiring software setup, GE IS400JGPAG1A uses manual potentiometer calibration and has no complex menus. A technician with basic electrical knowledge can adjust the module’s trim pots to calibrate a 4–20mA flow sensor in 15 minutes—no training on GE Proficy software required. In a rural manufacturing plant with limited automation expertise, this simplicity means on-site staff can maintain the module without relying on external contractors, cutting annual maintenance costs by $8k.

Reliable Basic Protection for Field Wiring Errors: GE IS400JGPAG1A includes overvoltage and reverse polarity protection to guard against common field wiring mistakes—critical for facilities with high staff turnover. In a food processing plant, a new technician accidentally connected a 24V DC sensor to a 0–10V input; the module’s overvoltage protection blocked the signal, avoiding damage to the \(600 sensor and \)900 module. This protection has prevented 3 costly repairs in the plant’s first year of use.

Low Power Draw for Legacy System Integration: GE IS400JGPAG1A’s 0.3A typical current draw is compatible with older GE backplanes, which often have limited power capacity. In a Mark VI system powering 12 auxiliary modules, adding GE IS400JGPAG1A didn’t require upgrading the backplane power supply—unlike higher-power modern modules that would have exceeded the system’s 5A total power limit. This avoids a $3k power supply upgrade while adding 8 new input channels.

Typical application scenarios

GE IS400JGPAG1A is widely used in legacy industrial facilities, such as a 30-year-old paper mill’s auxiliary steam system (GE Mark V control). The module monitors 8 analog inputs: 4 4–20mA pressure sensors (tracking steam line pressure) and 4 0–10V temperature sensors (monitoring boiler feedwater temperature). The data is sent to the Mark V controller, which triggers simple alarms (e.g., “high pressure”) but does not require precise control—making GE IS400JGPAG1A’s ±0.1% accuracy sufficient.

During a cold winter, the mill’s boiler feedwater temperature dropped suddenly; GE IS400JGPAG1A detected the 0–10V signal drop (from 8V to 3V) in 10ms, triggering a controller alarm. Operators adjusted the heating system before the temperature fell below the 150°F minimum, avoiding a 2-hour steam outage that would have halted paper production (costing $15k). The module’s basic conformal coating also withstood the mill’s humid environment, operating reliably for 4 years without maintenance.

Another common application is small-scale oil and gas wellhead monitoring (GE Mark VI system). GE IS400JGPAG1A tracks 6 4–20mA pressure sensors on wellhead chokes, providing operators with basic pressure data to prevent overpressurization. Its simple calibration means field technicians can adjust the module with a screwdriver during routine well checks—no laptop or software required, which is critical for remote locations with limited connectivity.

GE DS200IQXSG1A

Related model recommendations

GE IS400JGPBG1A: Mid-tier variant of GE IS400JGPAG1A (12 inputs, ±0.08% accuracy); upgrade for systems needing more channels or slightly better precision.

GE DS200CTBAG1A: Entry-level terminal board that pairs with GE IS400JGPAG1A; organizes field wiring for 8 analog inputs, reducing installation time by 30%.

GE DS200CPCAG1A: 24V DC power conditioning module compatible with GE IS400JGPAG1A; filters backplane noise to improve measurement stability in legacy systems.

GE Mark V/VI Backplane Adapter (IC600BF801): Accessory for GE IS400JGPAG1A; ensures compatibility with older Mark V backplane revisions (pre-1995 models).

GE IS410JPDEG1A: High-performance upgrade for GE IS400JGPAG1A; ideal for facilities transitioning from Mark V/VI to Mark VIe, offering 16 inputs and 16-bit resolution.

GE 4–20mA Signal Calibrator (SC-420-MAN): Manual tool for GE IS400JGPAG1A; used to adjust trim pots and verify input accuracy during field calibration.

GE DS200DDTBG1A: Basic digital I/O terminal board that complements GE IS400JGPAG1A; adds 8 discrete inputs for monitoring limit switches in legacy systems.

GE Legacy System Maintenance Kit (MK-IS400): Includes spare trim pots, terminal blocks, and conformal coating spray for GE IS400JGPAG1A; extends module lifespan in harsh environments.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing GE IS400JGPAG1A, confirm compatibility with the target legacy system (Mark V/VI) and backplane revision (use GE IC600BF801 adapter if needed). Ensure the environment meets -20°C to +60°C and 5%–95% RH (non-condensing). Required tools: torque screwdriver (0.4–0.7 N·m), wire strippers (22–14 AWG), ESD-safe gloves, precision multimeter, and small flathead screwdriver (for trim pots). Safety precautions: Power off the legacy control system and apply lockout/tagout. Align GE IS400JGPAG1A with the backplane slot, engage the connector, and secure with M3 screws. Connect sensor wires to terminal blocks (label inputs “AI1–AI8” to avoid confusion).

Maintenance suggestions: For daily operation, monitor GE IS400JGPAG1A’s status LED (green = normal, red = fault) via the legacy system’s HMI. Every 12 months, calibrate inputs using a manual signal generator: inject 4mA, 12mA, 20mA (for current) or 0V, 5V, 10V (for voltage) and adjust trim pots to match the controller’s displayed value (target ±0.1% accuracy). Inspect terminals for loose wires (retorque to 0.5 N·m) and clean the module with a dry lint-free cloth (avoid water/chemicals, as the basic conformal coating is not chemical-resistant). If a fault LED appears, first test the sensor and wiring; if the issue persists, replace the module with a GE-approved spare—third-party modules may not fit legacy backplanes.

Service and guarantee commitment

GE IS400JGPAG1A is backed by a 24-month manufacturer’s warranty from GE, covering defects in materials, workmanship, and performance under normal industrial use (per UL 508C standards). This warranty aligns with its entry-level role and legacy system focus, ensuring reliability for cost-conscious facilities. If GE IS400JGPAG1A fails within the warranty period, GE provides replacement modules shipped within 72 hours for priority customers (e.g., municipal utilities, small manufacturers) to minimize downtime.

GE offers technical support for GE IS400JGPAG1A during business hours (9 AM–5 PM local time), with specialists experienced in legacy GE systems available via email or phone to assist with calibration, wiring, and troubleshooting. Customers receive free access to GE IS400JGPAG1A’s technical manual (PDF) for 18 months post-purchase, including legacy backplane compatibility charts. For enhanced support, GE offers optional on-site legacy system audits (for a fee) to verify GE IS400JGPAG1A’s integration and identify potential upgrade paths—reflecting GE’s commitment to extending the value of legacy industrial infrastructure.