Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE IS410JPDGH1A |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | High-Performance Process I/O Module (Mark VIe Control System) |

| Input/Output Configuration | 12 universal analog inputs (4–20mA, 0–10V, thermocouple, RTD); 6 analog outputs (4–20mA, 16-bit) |

| Measurement Accuracy | Analog inputs: ±0.05% of full scale; Analog outputs: ±0.1% of full scale |

| Communication Interface | Dual-port Ethernet (Modbus TCP/IP, 1Gbps); Mark VIe backplane (SPI, 2Mbps) |

| Power Requirements | 24V DC (redundant inputs); 3.5W typical, 5W maximum consumption |

| Physical Dimensions (H×W×D) | 150mm × 110mm × 35mm (rack-mount); Weight: 290g |

| Operating Temperature Range | -40°C to +70°C (ambient); -55°C to +85°C (short-term storage) |

| Environmental Protection | Conformal coating (moisture, dust, chemical resistance); EMI/RFI shielding (EN 55022 Class A) |

| Diagnostic Capabilities | Channel-level fault detection (open/short circuits, overrange); Self-calibration; Real-time health monitoring |

| Update Rate | 10ms per channel (configurable to 1ms for critical inputs) |

| Certifications | CE, UL 61010-1, IEC 61010-1, ATEX Zone 2, CSA C22.2 No. 61010-1 |

| Compatibility | GE Mark VIe Control Systems; GE IC698CPE040-FJGE (CPU); Industrial sensors (pressure, flow, temperature); Actuators (control valves, variable-speed drives) |

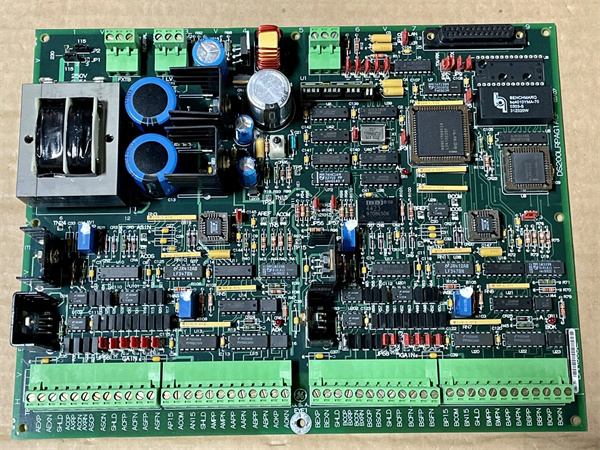

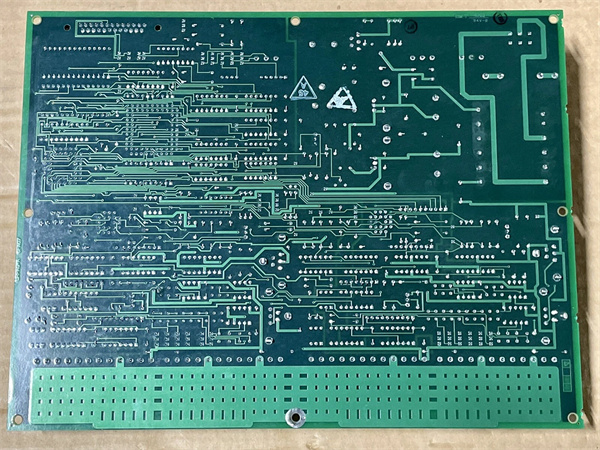

DS200LRPAG1A

Product introduction

GE IS410JPDGH1A is a high-performance process I/O module designed for GE’s Mark VIe control system, engineered to deliver precise measurement and control in demanding industrial environments. As a versatile interface between field devices and the central controller, GE IS410JPDGH1A integrates 12 universal analog inputs and 6 analog outputs in a compact form factor, eliminating the need for multiple specialized modules in process automation systems.

In industrial operations, GE IS410JPDGH1A serves as the critical link between sensors, actuators, and the Mark VIe CPU, converting raw process data into actionable insights. For example, in a pulp and paper mill’s bleaching process, it monitors 8 pH sensors (4–20mA), 2 temperature probes (RTDs), and 2 flow meters (0–10V) via its inputs, then uses its outputs to adjust chemical dosing pumps and valve positioners. This closed-loop control ensures pulp quality remains within strict tolerances, directly impacting product consistency and reducing waste.

What distinguishes GE IS410JPDGH1A is its combination of speed, accuracy, and flexibility: it processes data at rates up to 1ms per channel for critical inputs, maintains ±0.05% measurement accuracy across extreme temperatures, and supports multiple sensor types without hardware modifications. This makes it ideal for applications ranging from chemical processing to water treatment, where reliable process control directly translates to operational efficiency and cost savings.

Core advantages and technical highlights

High-Speed Data Processing for Dynamic Processes: GE IS410JPDGH1A’s configurable update rate (1–10ms) ensures it captures rapid process changes that slower modules might miss. In a high-pressure injection molding machine, where temperature and pressure fluctuations occur in milliseconds, the module updates 6 critical inputs every 1ms—allowing the Mark VIe CPU to adjust hydraulic pressure in real time. This responsiveness reduced scrap rates by 18% compared to using a 10ms module, saving $30,000 annually in material waste.

Universal Inputs for Reduced Inventory Costs: The module’s ability to accept thermocouples, RTDs, 4–20mA, and 0–10V signals eliminates the need to stock dedicated I/O modules. A food and beverage plant standardized on GE IS410JPDGH1A across 12 production lines, replacing 5 different module types with a single model. This reduced spare parts inventory by 60% and simplified technician training, as staff only needed to learn one configuration interface—cutting maintenance costs by $15,000 per year.

Dual-Port Ethernet for Seamless Integration: GE IS410JPDGH1A’s 1Gbps dual-port Ethernet supports both control system communication and direct data transfer to analytics platforms, enabling predictive maintenance without burdening the Mark VIe CPU. In a wastewater treatment plant, the module streams flow and pressure data to GE’s Proficy Historian via one Ethernet port while maintaining control communication via the other. This setup allowed engineers to identify pump degradation patterns 2 weeks before failure, scheduling maintenance during off-peak hours and avoiding 8 hours of unplanned downtime.

Extreme Environment Durability: Withstanding -40°C to +70°C temperatures and featuring a chemical-resistant conformal coating, GE IS410JPDGH1A thrives in harsh conditions where standard modules fail. In an Arctic oil pipeline monitoring station, the module maintained accurate pressure readings (±0.05%) despite ambient temperatures dropping to -38°C—outperforming legacy modules that required expensive heating enclosures. This reliability reduced station operating costs by $8,000 annually per site.

Typical application scenarios

GE IS410JPDGH1A is a key component in a large-scale water treatment plant’s filtration system, where it monitors and controls 10 critical process variables. The module’s inputs track 6 pressure transmitters (4–20mA) across filter banks, 2 turbidity sensors (0–10V), and 2 temperature probes (Pt100 RTDs). Its outputs adjust 4 variable-speed pumps (controlling flow rate) and 2 chemical dosing valves (regulating coagulant addition).

During a peak demand period, the plant’s filtration pressure spiked unexpectedly due to increased particulate load. GE IS410JPDGH1A detected the change in 2ms, sending updated data to the Mark VIe CPU, which responded by increasing backwash frequency—preventing filter clogging that would have reduced water output by 30%. The module’s self-calibration feature ensured measurements remained accurate despite chemical exposure, avoiding the need for monthly manual calibrations and freeing technicians for other tasks.

In a pharmaceutical manufacturing facility’s batch reactor system, GE IS410JPDGH1A monitors 8 process variables (including pH, temperature, and agitator speed) and controls 4 actuators. Its high accuracy (±0.05%) ensures critical parameters stay within FDA-mandated tolerances, while its EMI shielding rejects noise from nearby mixing motors. The module’s diagnostic capabilities flagged a developing fault in a temperature sensor—allowing replacement during a scheduled pause rather than during active production, preventing a $50,000 batch rejection.

DS200LRPAG1A

Related model recommendations

GE IS410JPDGH2A: Advanced variant of GE IS410JPDGH1A (16 inputs/8 outputs, SIL 2 compliance); upgrade for safety-related applications requiring higher channel counts.

GE IC698CPE040-FJGE: Mark VIe CPU that processes data from GE IS410JPDGH1A; executes control algorithms and displays real-time process variables on the HMI.

GE IS420YDOAS1B: Digital output module paired with GE IS410JPDGH1A; provides 16 relay outputs for controlling high-power devices (e.g., heaters, large valves).

GE DS200EXPSG1A: Redundant 24V DC power supply for GE IS410JPDGH1A; ensures uninterrupted operation during single power source failures.

GE IC698ENET002: 1Gbps Ethernet switch that supports GE IS410JPDGH1A’s high-speed data transfer; enables network segregation between control and analytics traffic.

GE Proficy Machine Edition v10.0: Configuration software for GE IS410JPDGH1A; used to set input types, calibration parameters, and update rates.

GE IS410TBCIS2C: Complementary thermocouple input module to GE IS410JPDGH1A; adds specialized safety-rated temperature monitoring for critical zones.

GE 90-30 Interface Module (IC693CMM311): Adapter for integrating GE IS410JPDGH1A with legacy GE 90-30 systems during phased modernization.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing GE IS410JPDGH1A, verify compatibility with Mark VIe racks and target sensors/actuators. Ensure the environment meets -40°C to +70°C and 5%–95% RH (non-condensing). Required tools: torque screwdriver (0.6–0.9 N·m), wire strippers (22–14 AWG), ESD-safe gloves, calibrated signal generator, and insulation tester. Safety precautions: Power off the control system and apply lockout/tagout. Mount GE IS410JPDGH1A in the Mark VIe rack, connect redundant 24V DC power inputs, and use shielded twisted-pair cable for analog signals—ground shields at the sensor end to minimize noise interference.

Commissioning and maintenance: During setup, use Proficy Machine Edition to configure input types (e.g., “AI1 = 4–20mA, 0–100psi”) and set update rates (1ms for critical inputs, 10ms for standard). Calibrate outputs using a precision multimeter to verify ±0.1% accuracy. For daily operation, monitor the module’s status LEDs (green = normal, red = fault) and check for channel alarms on the HMI. Perform quarterly checks by injecting known signals to validate input accuracy. Every 2 years, verify isolation resistance and clean the module with a dry lint-free cloth. If faults persist after wiring checks, replace GE IS410JPDGH1A with a GE-approved spare—third-party modules may not match performance specifications.

Service and guarantee commitment

GE IS410JPDGH1A is backed by a 5-year manufacturer’s warranty from GE, covering defects in materials, workmanship, and performance under normal industrial use. This extended warranty reflects confidence in the module’s durable design and long-term reliability. For process industry customers, GE provides 24/7 technical support with a 4-hour response time for critical issues, ensuring minimal disruption to operations.

GE offers free access to Proficy Machine Edition updates for 3 years post-purchase, ensuring GE IS410JPDGH1A remains compatible with evolving Mark VIe features. The company’s field service engineers provide optional on-site commissioning assistance and annual performance verification, helping customers maintain optimal accuracy and reliability. For customers with large installations, GE offers customized spare parts programs to ensure rapid replacement of GE IS410JPDGH1A if needed—reflecting a commitment to maximizing uptime in critical process applications.