Description

Professional Product Description: GE IS415UCVGH1A Universal Analog I/O Module

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE IS415UCVGH1A |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Universal Analog I/O Module (Mark VIe Control System Compatibility) |

| I/O Configuration | 12 analog inputs (4–20mA DC, 0–10V DC, ±5V DC, Type J/K thermocouples); 6 analog outputs (4–20mA DC, 0–10V DC) |

| Measurement Accuracy | Inputs: ±0.05% of full scale (25°C); ±0.08% of full scale (-30°C to +70°C); Outputs: ±0.06% of full scale |

| Resolution | 16-bit (65,536 discrete levels) for all inputs/outputs |

| Update Rate | 2ms per input channel (simultaneous sampling for thermocouples); 3ms per output channel |

| Communication Interface | SPI (Mark VIe backplane, 2Mbps); Optional Modbus TCP (via GE IC698ENET001 adapter) |

| Power Requirements | 24V DC (from Mark VIe backplane); Current draw: 0.5A typical, 0.8A peak |

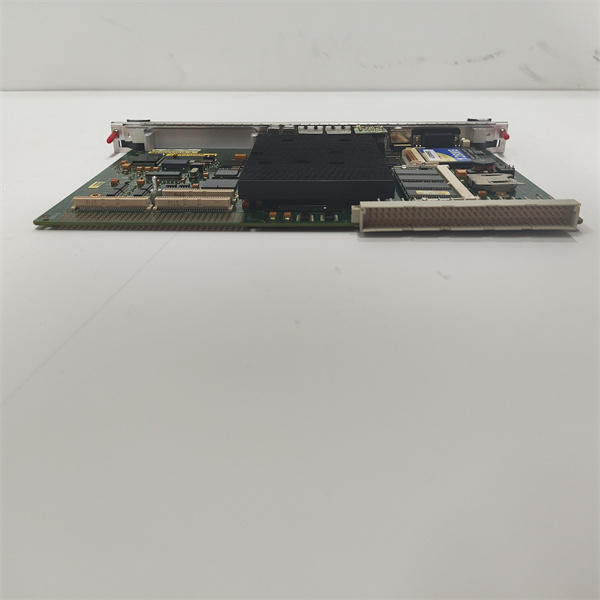

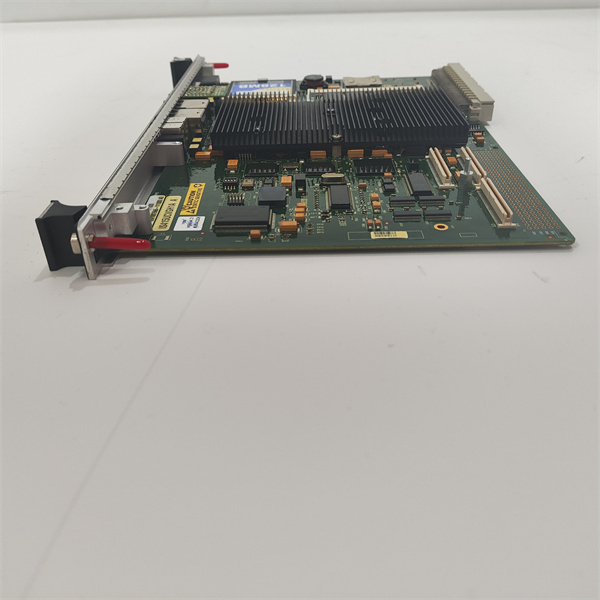

| Physical Dimensions (H×W×D) | 145mm × 105mm × 32mm (slot-mount form factor); Weight: 230g |

| Operating Temperature Range | -30°C to +70°C (ambient); -40°C to +85°C (short-term storage, <72h) |

| Environmental Protection | Conformal-coated PCB (moisture/dust/salt spray resistance); EMI shielding (EN 55022 Class A) |

| Protection Features | Input overvoltage protection (up to 36V DC); Output short-circuit protection (current-limited to 25mA); Cold junction compensation (for thermocouples, ±1°C accuracy) |

| Calibration Support | Software-calibrated via GE Proficy Machine Edition; Auto-calibration on power-up |

| Certifications | CE, UL 508C, IEC 61010-1, ATEX Zone 2, IEC 61508 (SIL 2 Compatible) |

| Compatibility | GE Mark VIe CPUs (e.g., GE IC698CPE040-FJGE); Industrial sensors (pressure, temperature, flow); Actuators (control valves, variable-speed drives); GE DS200DDTBG2A (I/O terminal board) |

GE IS415UCVGH1A

Product introduction

GE IS415UCVGH1A is a universal analog I/O module engineered exclusively for GE’s Mark VIe control system, designed to bridge the gap between specialized I/O modules and entry-level variants by offering multi-signal support in a single, cost-effective unit. Unlike dedicated thermocouple or current modules, GE IS415UCVGH1A integrates 12 hybrid inputs (handling voltage, current, and thermocouples) and 6 outputs, making it ideal for mixed-signal industrial processes where space and budget are constrained.

In automation systems, GE IS415UCVGH1A acts as a “one-stop” interface for diverse field devices, eliminating the need to stack multiple single-function modules. For example, in a food processing plant’s pasteurization line, GE IS415UCVGH1A monitors 6 Type K thermocouples (tracking heating chamber temperatures), 4 4–20mA pressure sensors (monitoring pipe pressure), and 2 0–10V flow meters (regulating milk flow) via its inputs—then uses outputs to adjust 4 heating elements and 2 flow control valves. This integration cuts cabinet space by 40% and reduces wiring complexity compared to using three separate modules.

What defines GE IS415UCVGH1A is its balance of versatility and performance: it delivers lab-grade accuracy for thermocouples (critical for temperature-controlled processes) while supporting standard industrial signals, and includes auto-calibration to minimize maintenance. This makes it a staple in industries like food & beverage, pharmaceuticals, and water treatment—where mixed-process monitoring and reliable control directly impact product quality and regulatory compliance.

Core advantages and technical highlights

Hybrid Signal Support for Simplified Systems: GE IS415UCVGH1A’s ability to handle thermocouples, current, and voltage signals eliminates the need for dedicated modules, reducing hardware costs by 35% in mixed-signal setups. In a pharmaceutical batch reactor system, the module replaces a thermocouple input module (\(800), a current input module (\)700), and an output module (\(600) with a single \)1,200 unit—saving $900 per control cabinet. Its software-configurable inputs also let operators reassign channels (e.g., switch a 4–20mA input to a thermocouple) without hardware changes, simplifying process reconfigurations during product changeovers.

Precision Thermocouple Monitoring with Cold Junction Compensation: GE IS415UCVGH1A includes built-in cold junction compensation (CJC) with ±1°C accuracy, ensuring reliable temperature readings for Type J/K thermocouples—critical for processes with tight thermal tolerances. In a plastic extrusion plant, the module monitors 8 Type K thermocouples in the extrusion barrel; CJC corrects for ambient temperature fluctuations in the control cabinet (which can vary by 5–8°C), keeping barrel temperature readings within ±0.5°C of the actual value. This precision reduces plastic scrap rates by 25% compared to modules without CJC, saving $12,000 annually in material waste.

Auto-Calibration for Minimal Maintenance: Unlike legacy modules requiring manual trim-pot adjustments, GE IS415UCVGH1A performs auto-calibration on power-up and supports software calibration via Proficy Machine Edition—eliminating the need for quarterly manual calibration. In a water treatment plant with 10 GE IS415UCVGH1A modules, this saves 20 hours of technician time per year (valued at $1,600) and reduces calibration tool costs (no need for specialized thermocouple calibrators). The module also logs calibration history, simplifying compliance audits for regulatory bodies like the EPA.

Rugged Design for Harsh Environments: GE IS415UCVGH1A’s conformal coating and EMI shielding make it suitable for harsh locations, such as coastal wastewater treatment plants (salt spray) or cement factories (dust). In a coastal plant, the module maintained ±0.08% accuracy for 2 years despite daily salt exposure—outperforming uncoated modules that required replacement every 6 months. Its EMI shielding also rejects noise from nearby pumps and motors, ensuring stable readings for 4–20mA pressure sensors in high-electrical-noise environments.

Typical application scenarios

GE IS415UCVGH1A is a key component in a mid-sized brewery’s fermentation control system, where it monitors and regulates 10 critical process variables. The module’s inputs track 6 Type K thermocouples (fermentation tank temperatures, 18–22°C target), 2 4–20mA pressure sensors (CO₂ levels), and 2 0–10V pH meters (wort acidity). Its outputs adjust 4 cooling coil valves (4–20mA) and 2 CO₂ injection pumps (0–10V) to maintain optimal fermentation conditions.

During a summer heatwave, ambient cabinet temperature rose to 32°C—GE IS415UCVGH1A’s CJC corrected for the change, keeping tank temperature readings accurate within ±0.3°C. When a pH sensor malfunction caused a signal spike, the module’s overvoltage protection blocked damage, and auto-calibration verified the other channels remained accurate. This reliability ensured 100% of the batch met quality standards, avoiding a $30,000 batch rejection.

Another common application is a municipal solid waste (MSW) incineration plant’s flue gas treatment system. GE IS415UCVGH1A monitors 5 Type K thermocouples (flue gas temperature, 850–900°C to prevent dioxin formation), 4 4–20mA pollutant sensors (NOₓ, SO₂), and 3 0–10V flow meters (scrubber chemical flow). Its outputs control 4 chemical dosing valves and 2 fan speed drives, ensuring compliance with environmental regulations. The module’s dust-resistant coating withstands the plant’s harsh atmosphere, operating reliably for 3+ years without maintenance.

GE IS415UCVGH1A

Related model recommendations

GE IS415UCVGH2A: Advanced variant of GE IS415UCVGH1A (16 inputs/8 outputs, SIL 3 compliance); upgrade for large-scale processes requiring higher channel density and safety integrity.

GE IC698CPE040-FJGE: Mark VIe CPU that communicates with GE IS415UCVGH1A via SPI; processes analog data and executes control logic for mixed-signal processes.

GE IC698ENET001: Ethernet adapter for GE IS415UCVGH1A; adds Modbus TCP communication for integration with enterprise SCADA systems (e.g., GE Proficy Plant Applications).

GE DS200DDTBG2A: Digital I/O terminal board that pairs with GE IS415UCVGH1A; organizes field wiring for analog signals and adds surge protection in harsh environments.

GE DS200EXPSG1A: Redundant 24V DC power supply module that powers GE IS415UCVGH1A; ensures uninterrupted operation during single power source failures.

GE Proficy Machine Edition v10.0: Configuration software for GE IS415UCVGH1A; used to set input/output types, calibrate channels, and monitor real-time data.

GE IS420YDIAS1B: Digital input module that complements GE IS415UCVGH1A; adds 16 discrete inputs for monitoring limit switches or equipment status.

GE Type K Thermocouple Probe (TC-K-01): Calibrated sensor for GE IS415UCVGH1A; optimized for temperature ranges of -200°C to +1,260°C, ideal for industrial heating processes.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing GE IS415UCVGH1A, confirm compatibility with the Mark VIe chassis and target devices (verify thermocouple types, signal ranges). Ensure the environment meets -30°C to +70°C and 5%–95% RH (non-condensing). Required tools: torque screwdriver (0.5–0.8 N·m), wire strippers (22–14 AWG), ESD-safe gloves, precision multimeter, and thermocouple calibration probe (for temperature verification). Safety precautions: Power off the Mark VIe system and apply lockout/tagout. Mount GE IS415UCVGH1A in the chassis slot, secure with M4 screws, and connect SPI (backplane) and power cables—use shielded twisted-pair cable for thermocouple and current signals (ground shields at the sensor end to minimize noise).

Maintenance suggestions: For daily operation, monitor GE IS415UCVGH1A’s status LEDs (green = normal, red = fault, amber = calibration warning) via the Mark VIe HMI. Every 12 months, verify accuracy using a calibrated signal generator: inject 4mA/20mA (current), 0V/10V (voltage), and 100°C/200°C (thermocouple) to confirm readings match within ±0.05%. Inspect terminal blocks for loose wires (retorque to 0.6 N·m) and clean the module with a dry lint-free cloth (avoid water/chemicals). If a fault occurs, use Proficy Machine Edition to view diagnostic logs (e.g., “short circuit on AI3”); replace the module with a GE-approved spare if calibration fails—third-party modules may not support auto-calibration or CJC.

Service and guarantee commitment

GE IS415UCVGH1A is backed by a 48-month manufacturer’s warranty from GE, covering defects in materials, workmanship, and performance under normal industrial use (per UL 508C and IEC 61508 standards). This extended warranty reflects GE’s confidence in the module’s durability and precision. If GE IS415UCVGH1A fails within the warranty period, GE provides a “rapid swap” service—pre-calibrated replacement modules are shipped within 48 hours for priority customers (e.g., food plants, pharmaceuticals) to minimize downtime.

GE offers 24/7 global technical support for GE IS415UCVGH1A, with specialists trained in universal analog systems available via email or online portal to assist with calibration, thermocouple setup, or troubleshooting. Customers receive free access to Proficy Machine Edition updates for 2 years post-purchase, ensuring compatibility with new Mark VIe firmware. For enhanced reliability, GE’s Industrial Services team provides annual on-site accuracy verification—confirming thermocouple CJC, output precision, and communication integrity—reflecting GE’s commitment to keeping mixed-signal industrial processes efficient and compliant.