Description

Professional Product Description: GE IS420ESWAH3A Specialized Module (Mark VIe Series)

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE IS420ESWAH3A |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Specialized Module for Mark VIe Series (Enhanced Supervisory and Control Functionality) |

| Input/Output Configuration | Multiple configurable input channels for sensor data (e.g., temperature, pressure, vibration sensors); 8 high – current relay outputs (10A per channel) for controlling heavy – duty equipment |

| Communication Protocols | Supports Modbus RTU/TCP for external device communication; CANopen for in – system network communication; 100Mbps Ethernet for high – speed data transfer to the Mark VIe CPU |

| Power Requirements | 120V AC/240V AC (auto – sensing); Power consumption: 30W typical, 40W maximum |

| Physical Dimensions (H×W×D) | 150mm × 120mm × 40mm (rack – mount form factor); Weight: 350g |

| Mounting Compatibility | Compatible with Mark VIe standard 19 – inch racks; Requires GE IC698RCM008 rack – mounting kit for installation |

| Operating Temperature Range | – 20°C to + 60°C (ambient); – 30°C to + 70°C (short – term storage, < 48h) |

| Environmental Protection | Dust – resistant enclosure (IP54); EMI/RFI shielding to withstand electromagnetic interference; Surge protection (up to 6kV) for power and signal lines |

| Certifications | CE, UL 61010 – 1, IEC 61508 (SIL 1 compliant), RoHS compliant |

| Compatibility | GE Mark VIe Control Systems; Industrial sensors (temperature, pressure, vibration); Heavy – duty actuators (e.g., large – scale contactors, motor starters) |

| Control and Monitoring Features | Built – in data logging for up to 10,000 events; Real – time trend analysis for input parameters; Programmable logic control (PLC) – like functions for custom control logic |

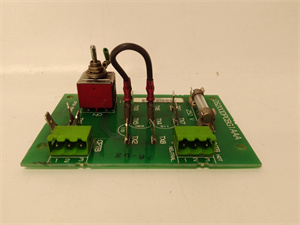

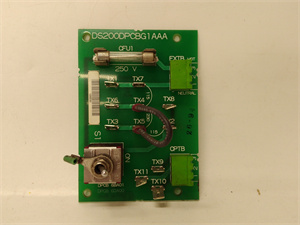

GE DS200DPCBG1A IOS

Product Introduction

GE IS420ESWAH3A is a specialized module meticulously designed for GE’s Mark VIe control systems, catering to industries with complex monitoring and control requirements. This module serves as a critical interface between various industrial sensors and actuators, and the Mark VIe central control unit.

In industrial settings, it plays a pivotal role in gathering real – time data from sensors. For example, in a large – scale petrochemical plant, it can collect temperature data from hundreds of reactors and heat exchangers, pressure data from pipelines, and vibration data from rotating equipment such as pumps and compressors. The module then processes this data and uses its 8 high – current relay outputs to control heavy – duty equipment, like large – scale motor starters that power the plant’s main production machinery.

What sets the GE IS420ESWAH3A apart is its versatility and reliability. It can adapt to different industrial communication protocols, ensuring seamless integration into existing systems. Its built – in data logging and real – time trend analysis features enable operators to proactively monitor and maintain the plant’s equipment, reducing unplanned downtime.

Core Advantages and Technical Highlights

Multi – protocol Communication for Seamless Integration

The GE IS420ESWAH3A supports multiple communication protocols, which is a significant advantage in multi – vendor and multi – technology industrial environments. In a power generation facility that uses a mix of different sensor and actuator brands, the module can communicate with Modbus – compatible sensors to gather data and then use CANopen to transfer this data within the local control network. The 100Mbps Ethernet interface ensures fast and reliable data transfer to the Mark VIe CPU, enabling quick decision – making and control actions.

High – Current Relay Outputs for Heavy – Duty Control

With 8 high – current relay outputs, each capable of handling 10A, the module is well – equipped to control heavy – duty industrial equipment. In a mining operation, it can directly control the large – scale contactors that power conveyor belts, crushers, and other essential machinery. This eliminates the need for additional intermediate relays in many cases, simplifying the control system and reducing the overall cost and complexity.

Advanced Data Logging and Trend Analysis

The built – in data logging feature of the GE IS420ESWAH3A can record up to 10,000 events. In a manufacturing plant, it can log events such as sensor alarms, equipment startups and shutdowns, and changes in operating parameters. The real – time trend analysis function allows operators to visualize how parameters like temperature or pressure are changing over time. For instance, by analyzing the temperature trend of a critical manufacturing process, operators can predict when equipment might overheat and take preventive maintenance actions, potentially saving thousands of dollars in repair costs and lost production time.

Programmable Logic Control – like Functions

The module offers PLC – like functions, allowing users to create custom control logic. In a water treatment plant, operators can program the module to control the sequence of pumps, valves, and filters based on water quality parameters. For example, if the turbidity of the incoming water exceeds a certain threshold, the module can automatically adjust the speed of the filtration pumps and open additional bypass valves, optimizing the water treatment process without the need for a separate PLC.

Typical Application Scenarios

Petrochemical Plants

In petrochemical plants, the GE IS420ESWAH3A is used to monitor and control a wide range of processes. It can collect data from thousands of temperature sensors installed in reactors, distillation columns, and storage tanks. By analyzing this data in real – time, it can control the heating and cooling systems to maintain optimal process temperatures. For example, during a change in production product, the module can adjust the temperature setpoints of reactors based on pre – programmed logic, ensuring a smooth transition and high – quality product output.

Power Generation Facilities

In power plants, whether they are coal – fired, gas – fired, or nuclear, the module plays a crucial role. It can monitor the vibration of turbines, the pressure of steam lines, and the temperature of generators. If it detects abnormal vibration in a turbine, it can immediately send an alarm to the control room and initiate a shutdown sequence using its high – current relay outputs to protect the expensive equipment. In addition, it can communicate with other power plant systems, such as the boiler control system, to optimize the overall power generation process.

Manufacturing Plants

Manufacturing plants rely on the GE IS420ESWAH3A for process control and quality monitoring. In an automotive manufacturing plant, it can monitor the pressure and temperature in paint spray booths to ensure consistent paint quality. If the temperature in a paint booth drops below the optimal range, the module can automatically adjust the heating system and slow down the production line to prevent paint defects. It can also control the operation of robotic arms and conveyor belts based on the production schedule and product quality requirements.

GE DS200DPCBG1A IOS

Related Model Recommendations

GE IS420ESWAI3A: A complementary input – only module that expands the sensor – connection capabilities of the GE IS420ESWAH3A. It has more high – precision analog input channels, suitable for applications that require extremely accurate sensor data collection.

GE IC698CPE040 – FJGE: The Mark VIe CPU that receives data from the GE IS420ESWAH3A and processes it for overall system control. It can execute complex control algorithms based on the data provided by the module.

GE DS200DDTBG2A: A digital I/O terminal board that can be used in conjunction with the GE IS420ESWAH3A to interface with digital sensors and actuators. It provides additional protection and signal conditioning for the module’s I/O signals.

GE DS200EXPSG1A: A power supply module that ensures stable power to the GE IS420ESWAH3A. It can handle voltage fluctuations commonly found in industrial environments, ensuring the module’s reliable operation.

GE IC698RCM008: The rack – mounting kit required for installing the GE IS420ESWAH3A in a standard 19 – inch rack. It provides a secure and organized mounting solution.

GE Proficy Machine Edition v10.0: Configuration software for the GE IS420ESWAH3A. It allows users to program the module’s custom control logic, set up data logging parameters, and configure communication protocols.

GE DS200DCVAG2A: A DC voltage monitoring module that can be used with the GE IS420ESWAH3A to monitor the power supply voltage of connected sensors and actuators. This helps in detecting power – related issues before they cause equipment failures.

GE IS420ESWAB3A: A redundant version of the GE IS420ESWAH3A module, suitable for applications where high – availability is critical. It has dual power inputs and redundant communication channels to ensure continuous operation in case of a component failure.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the GE IS420ESWAH3A, ensure that the target environment meets the operating temperature and humidity requirements (- 20°C to + 60°C ambient and 5% – 95% RH non – condensing). Verify compatibility with the Mark VIe 19 – inch rack and the GE IC698RCM008 rack – mounting kit. Gather the necessary tools, including a torque screwdriver (0.8 – 1.2 N·m), wire strippers (18 – 10 AWG), ESD – safe gloves, a multimeter, and an insulation tester. Power off the Mark VIe system and apply lockout/tagout procedures for safety.

Align the module with the rack – mounting kit and secure it using the provided screws. Connect the power supply wires, ensuring proper voltage selection (120V AC or 240V AC). Connect the communication cables (Ethernet, Modbus, CANopen) according to the system design. For sensor and actuator connections, use shielded cables to reduce electromagnetic interference. Verify all connections for proper polarity and tightness.

Maintenance Suggestions

For daily operation, monitor the module’s status through the Mark VIe HMI. Check for any abnormal power consumption (above 40W), communication errors, or sensor data outliers. Every 3 months, inspect the physical connections, including power and signal cables, for signs of wear or looseness. Retorque the screws to 1.0 N·m if necessary. Clean the module’s enclosure with a dry, lint – free cloth to maintain dust resistance.

Once a year, perform a comprehensive test of the module’s functions. Use a calibration tool to verify the accuracy of sensor inputs. Test the high – current relay outputs by simulating control signals and checking the operation of connected actuators. Update the module’s firmware using GE – approved software to ensure compatibility with the latest Mark VIe system enhancements and to address any known security vulnerabilities. If a component fails, replace it with a GE – approved spare part to maintain the module’s compliance with safety and performance standards.

Service and Guarantee Commitment

The GE IS420ESWAH3A comes with a 36 – month manufacturer’s warranty from GE. This warranty covers defects in materials, workmanship, and performance under normal industrial use, as per UL 61010 – 1 and IEC 61508 standards. In case of a module failure within the warranty period, GE offers a prompt replacement service. For priority customers, such as large – scale industrial plants, replacement modules can be shipped within 48 hours to minimize downtime.

GE provides 24/7 global technical support for the GE IS420ESWAH3A. Specialists trained in industrial control systems are available via phone and email to assist with installation, configuration, troubleshooting, and firmware updates. Customers also receive free access to the latest version of the GE Proficy Machine Edition software for 2 years after purchase, ensuring compatibility with new Mark VIe features and improvements. For customers in critical industries, GE can arrange for on – site technical support and maintenance services, further enhancing the reliability and performance of the GE IS420ESWAH3A in their operations.