Description

Product Overview

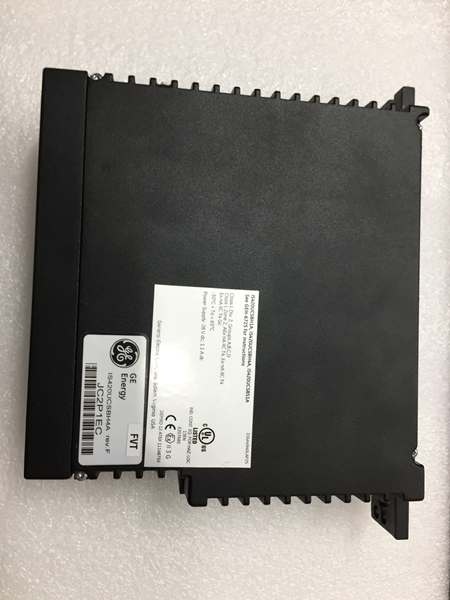

The GE IS420UCSBH3A is a high-performance analog I/O module designed for integration into Mark V gas turbine control systems. It handles critical signal conditioning and data acquisition tasks, ensuring precise monitoring and control of turbine performance parameters.

Role in Automation Systems:

-

Acts as an interface between field devices (e.g., LVDTs, servo valves) and the turbine control system.

-

Supports emergency shutdown protocols by validating sensor data during abnormal operating conditions.

Core Functionality:

-

Signal Conditioning: Scales and filters analog inputs (e.g., compressor stall detection signals).

-

Output Control: Drives servo valves and relays with ±0.5% accuracy.

-

Diagnostic Monitoring: Detects open-circuit or short-circuit faults in sensor lines.

Platform Integration:

-

Compatible with GE’s Mark V control systems and third-party DCS via 3PL bus.

-

Supports Modbus TCP for cross-platform communication.

GE IS420UCSBH3A

Technical Specifications

-

Model: IS420UCSBH3A

-

Manufacturer: GE

-

Product Type: Analog I/O Module

-

Signal Inputs:

-

Analog: 16 channels (4–20 mA, ±10 V DC)

-

Thermocouple: 8 channels (Type J/K, ±2.2 mV/°C)

-

-

Signal Outputs:

-

Analog: 8 channels (4–20 mA, ±10 V DC)

-

Relay: 4 channels (SPDT, 5 A/250 V AC)

-

-

Communication:

-

3PL Bus: 1 Mbps data rate

-

JE Connector: Generator/line signal interface

-

-

Environmental Ratings:

-

Temperature: -40°C to +85°C (storage), -20°C to +60°C (operating)

-

Humidity: 5–95% non-condensing

-

-

Certifications: UL 508, CE, ATEX Zone 2 (IIC)

Core Features & Customer Value

-

High-Accuracy Signal Processing:

-

Built-in 24-bit ADC ensures ±0.1% FS accuracy for critical turbine parameters (e.g., fuel flow, vibration).

-

Application: Maintains combustion efficiency in gas turbines by compensating for sensor drift.

-

-

Flexible Configuration:

-

Hardware jumpers (J1–J8) allow customization of output ranges (e.g., 4–20 mA or 0–20 mA).

-

Application: Adapts to varying turbine models without firmware updates.

-

-

Robust Fault Detection:

-

Auto-diagnostic alerts for open-circuit ( >500 Ω) or short-circuit ( <10 Ω) conditions.

-

Application: Prevents unplanned shutdowns in power plants by isolating faulty sensors.

GE IS420UCSBH3A

-

Typical Applications

-

Gas Turbine Control:

-

Compressor Stall Monitoring: Processes LVDT signals to detect rotor position deviations.

-

Example: Maintains stable output in combined-cycle plants during load fluctuations.

-

-

Power Plant Safety Systems:

-

Emergency Shutdown (ESD): Drives relay outputs to isolate fuel valves during over-temperature events.

-

-

Renewable Energy:

-

Wind Turbine Pitch Control: Regulates servo valves to adjust blade angles based on wind speed data.

-

Installation & Maintenance

-

Mounting: DIN rail or panel-mounting with IP20-rated enclosure.

-

Wiring: Pre-terminated connectors for sensors (e.g., 24 V DC thermocouples).

-

Diagnostics: LED indicators for communication status, overcurrent, and sensor faults alerts.

-

Service:

-

Annual calibration for analog inputs (±0.5% FS).

-

Field-replaceable input/output modules for minimal downtime.

-