Description

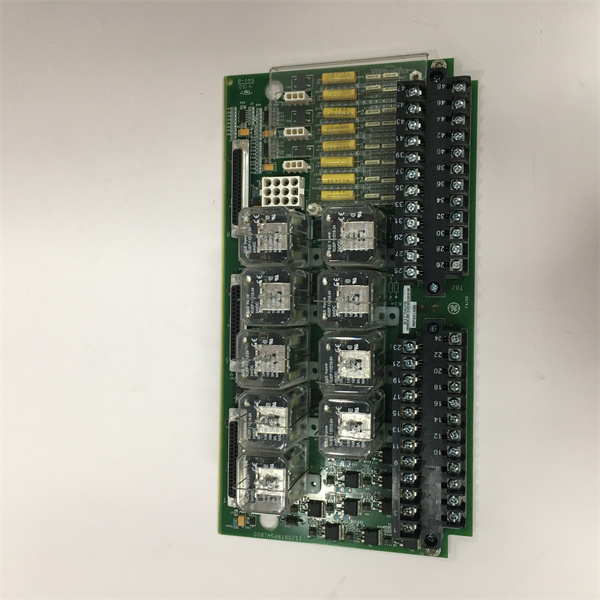

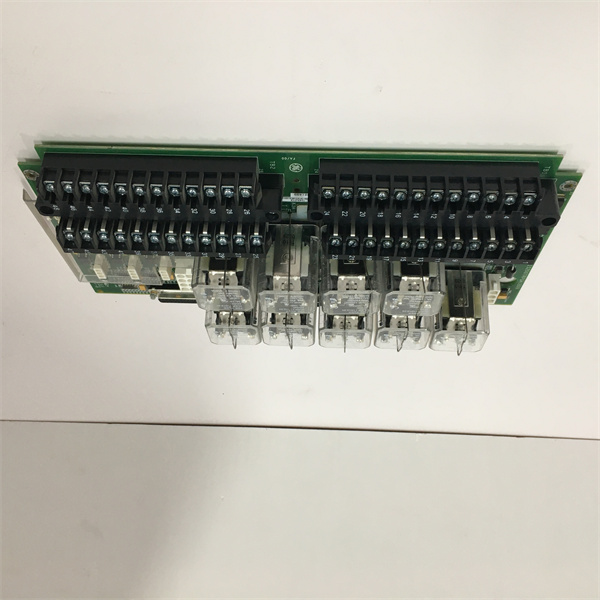

Product Overview

The GE MMI301 is a highly versatile and advanced module designed for industrial automation applications. As a key component in the industrial control ecosystem by General Electric, the GE MMI301 serves as a crucial interface between operators and industrial machinery. It is engineered to provide intuitive control and comprehensive monitoring capabilities, significantly enhancing the efficiency and productivity of manufacturing processes.

Functionally, the GE MMI301 comes with a high – resolution display, which could be a TFT with a resolution of 640 × 480 in some configurations. This enables operators to clearly view critical data related to industrial processes. It also offers multiple communication interfaces such as Ethernet, RS – 232, and USB. These interfaces facilitate seamless integration with various industrial systems and networks, ensuring smooth data exchange and effective system management. Additionally, it has a 128 MB flash memory, providing sufficient storage for necessary programs and data related to the operation and monitoring tasks. With an operating temperature range of – 40 °C to + 85 °C, the GE MMI301 is well – equipped to function reliably in harsh industrial environments.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | MMI301 |

| Manufacturer | General Electric |

| Product Type | Human – Machine Interface/Control Module |

| Operating Voltage | 24 VDC (Some sources also mention 120 VAC/230 VAC options) |

| Display Type | TFT (in some versions) |

| Resolution | 640 × 480 (for TFT display versions) |

| Communication Interfaces | Ethernet, RS – 232, USB |

| Memory Capacity | 128 MB flash |

| Operating Temperature Range | – 40 °C to + 85 °C |

| Storage Temperature Range | – 40 °C to + 85 °C |

| Dimensions | 20.3 cm x 15.2 cm x 10.2 cm (as per some listings) |

| Weight | 2.5 kg (as per some listings) |

Main Features and Advantages

User – Friendly Interface: The GE MMI301 features an intuitive design, making it easy for operators to interact with the industrial control system. The high – resolution display, whether it’s a TFT or other types, ensures clear visibility of data. For example, in a manufacturing plant, operators can quickly and accurately monitor system status, adjust settings, and receive real – time alerts, reducing the chances of errors and improving overall operational efficiency.

Robust Connectivity: With multiple communication interfaces like Ethernet, RS – 232, and USB, the module can be easily integrated into existing industrial setups. This allows for seamless data transfer between different components of the automation system. In a large – scale industrial complex, it can communicate with various sensors, actuators, and control units, enabling comprehensive system management and control.

Reliable Performance in Harsh Conditions: Built to withstand the rigors of industrial environments, the GE MMI301 can operate within a wide temperature range of – 40 °C to + 85 °C. Whether in a cold storage facility or a high – temperature manufacturing area, it maintains stable performance. This reliability ensures continuous operation of the industrial control system, minimizing downtime and production losses.

Ample Memory: The 128 MB flash memory provides sufficient space for storing programs, data logs, and configuration settings. This is beneficial for applications that require the storage of historical data for analysis or for running complex control algorithms. It allows the module to function independently for a certain period even in case of temporary communication disruptions with other parts of the system.

Robust Connectivity: With multiple communication interfaces like Ethernet, RS – 232, and USB, the module can be easily integrated into existing industrial setups. This allows for seamless data transfer between different components of the automation system. In a large – scale industrial complex, it can communicate with various sensors, actuators, and control units, enabling comprehensive system management and control.

Reliable Performance in Harsh Conditions: Built to withstand the rigors of industrial environments, the GE MMI301 can operate within a wide temperature range of – 40 °C to + 85 °C. Whether in a cold storage facility or a high – temperature manufacturing area, it maintains stable performance. This reliability ensures continuous operation of the industrial control system, minimizing downtime and production losses.

Ample Memory: The 128 MB flash memory provides sufficient space for storing programs, data logs, and configuration settings. This is beneficial for applications that require the storage of historical data for analysis or for running complex control algorithms. It allows the module to function independently for a certain period even in case of temporary communication disruptions with other parts of the system.

Application Field

Manufacturing Industry: In manufacturing plants, the GE MMI301 is extensively used for process control and monitoring. For instance, in an automotive assembly line, it can be used to control the operation of robotic arms, conveyor belts, and other automated machinery. Operators can use the module to set production parameters, monitor the progress of the assembly process, and receive alerts in case of any malfunctions. This helps in maintaining high – quality production and optimizing production speed.

Power Generation: In power plants, be it thermal, hydro, or wind, the GE MMI301 plays a vital role. In a thermal power plant, it can be used to monitor and control the operation of boilers, turbines, and generators. Operators can use the module to adjust the fuel supply, monitor the temperature and pressure of the steam, and ensure the safe and efficient operation of the power – generating equipment. In wind farms, it can be used to control the pitch and yaw of wind turbines, maximizing energy capture.

Industrial Automation in General: In any industrial setting where automation is implemented, the GE MMI301 can be a valuable asset. It can be used in packaging industries to control the operation of packaging machines, in food and beverage industries to monitor the production line, and in chemical plants to control the chemical reactions. Its versatility and reliability make it suitable for a wide range of industrial applications, enhancing the overall automation level and productivity.

Power Generation: In power plants, be it thermal, hydro, or wind, the GE MMI301 plays a vital role. In a thermal power plant, it can be used to monitor and control the operation of boilers, turbines, and generators. Operators can use the module to adjust the fuel supply, monitor the temperature and pressure of the steam, and ensure the safe and efficient operation of the power – generating equipment. In wind farms, it can be used to control the pitch and yaw of wind turbines, maximizing energy capture.

Industrial Automation in General: In any industrial setting where automation is implemented, the GE MMI301 can be a valuable asset. It can be used in packaging industries to control the operation of packaging machines, in food and beverage industries to monitor the production line, and in chemical plants to control the chemical reactions. Its versatility and reliability make it suitable for a wide range of industrial applications, enhancing the overall automation level and productivity.

Related Products

GE MMI302: Likely an upgraded version of the GE MMI301, it may offer enhanced features such as a higher – resolution display, more advanced communication protocols, or increased memory capacity. This could be suitable for applications with more demanding requirements for data visualization and processing.

GE Industrial Sensors: These sensors can be connected to the GE MMI301 to provide real – time data about various physical parameters in industrial processes. Different types of sensors, like temperature sensors, pressure sensors, and position sensors, can be integrated with the MMI301 to enable comprehensive monitoring and control.

GE PLC Controllers: Work in tandem with the GE MMI301 to execute control logic. The MMI301 provides the interface for operators to input commands and view system status, while the PLC controllers process these commands and control the operation of industrial equipment based on pre – programmed logic.

GE Ethernet Switches: As the GE MMI301 has Ethernet connectivity, these switches can be used to create a reliable and high – speed network infrastructure for data transfer between the MMI301 and other devices in the industrial automation system. They help in ensuring seamless communication and efficient data flow.

GE Power Supplies: Specific power supplies designed to provide stable and reliable power to the GE MMI301. Since the MMI301 can operate on different voltages (such as 24 VDC or 120/230 VAC), the appropriate power supply is crucial for its proper functioning.

GE Industrial Sensors: These sensors can be connected to the GE MMI301 to provide real – time data about various physical parameters in industrial processes. Different types of sensors, like temperature sensors, pressure sensors, and position sensors, can be integrated with the MMI301 to enable comprehensive monitoring and control.

GE PLC Controllers: Work in tandem with the GE MMI301 to execute control logic. The MMI301 provides the interface for operators to input commands and view system status, while the PLC controllers process these commands and control the operation of industrial equipment based on pre – programmed logic.

GE Ethernet Switches: As the GE MMI301 has Ethernet connectivity, these switches can be used to create a reliable and high – speed network infrastructure for data transfer between the MMI301 and other devices in the industrial automation system. They help in ensuring seamless communication and efficient data flow.

GE Power Supplies: Specific power supplies designed to provide stable and reliable power to the GE MMI301. Since the MMI301 can operate on different voltages (such as 24 VDC or 120/230 VAC), the appropriate power supply is crucial for its proper functioning.

Installation and Maintenance

Pre – installation preparation: Before installing the GE MMI301, first, ensure that the power to the relevant industrial control system is switched off to prevent electrical hazards. Check the installation environment to ensure it meets the temperature and humidity requirements specified for the module, typically – 40 °C to + 85 °C for operation. Inspect the module for any visible damage during transportation. When preparing to connect communication cables, make sure to use the correct cable types as per the interface requirements (e.g., Ethernet cables for Ethernet interface). Also, verify the compatibility of the GE MMI301 with other components in the system, such as the control units and sensors it will be communicating with.

Maintenance recommendations: Regularly monitor the GE MMI301 for any signs of abnormal operation. Check the display for any pixel – related issues or incorrect data representation. Ensure that the communication interfaces are functioning properly by periodically testing data transfer. Clean the module regularly to remove dust and debris, especially in dusty industrial environments, as these can affect the performance of the electronics. If any software – related issues occur, refer to the product manual for troubleshooting steps. In case of hardware component failure, replace the faulty parts with genuine GE – approved components to maintain the integrity and performance of the module.

Maintenance recommendations: Regularly monitor the GE MMI301 for any signs of abnormal operation. Check the display for any pixel – related issues or incorrect data representation. Ensure that the communication interfaces are functioning properly by periodically testing data transfer. Clean the module regularly to remove dust and debris, especially in dusty industrial environments, as these can affect the performance of the electronics. If any software – related issues occur, refer to the product manual for troubleshooting steps. In case of hardware component failure, replace the faulty parts with genuine GE – approved components to maintain the integrity and performance of the module.

Product Guarantee

General Electric offers a comprehensive product guarantee for the GE MMI301. The module undergoes strict quality control during the manufacturing process to meet high – industry standards. GE provides a warranty period, during which, if there are any defects in materials or workmanship, they will repair or replace the module free of charge. Their team of technical experts is available to offer support for installation guidance, configuration assistance, and troubleshooting. This reflects GE’s confidence in the product’s quality and its commitment to ensuring customer satisfaction in industrial automation applications. Whether it’s a small – scale industrial setup or a large – scale manufacturing plant, customers can rely on the GE MMI301 and the support provided by GE to keep their operations running smoothly.