Description

Detailed Parameter Table

| Parameter name | Parameter value |

| Product model | SR489 – P1 – HI – A20 – E |

| Manufacturer | GE (General Electric) |

| Product category | Generator Management Relay |

| Series | SR489 |

| Function | Manages and protects generators, ensuring stable operation |

| Phase current inputs | P1 – 1 A phase CT secondaries |

| Control power range | HI – 90 – 300 VDC / 70 – 265 VAC at 48 – 62 Hz |

| Analog outputs | A20 – 4 – 20 mA analog outputs |

| Display | E – Enhanced display, larger LCD |

| Protection features | Overcurrent, undervoltage, over / under frequency, loss of excitation, reverse power protection |

| Control features | Precise control of generator starting, stopping, and synchronization |

| Diagnostic features | Self – diagnostic capabilities for monitoring relay health |

| Communication interfaces | Supports multiple communication protocols for SCADA integration |

| Dielectric strength | 1.9 kV AC |

| Damped oscillation test rating | 2.5 kV |

| Operating temperature | – 40°C to 60°C |

| Storage temperature | Not specified (assumed within a reasonable range around operating temp) |

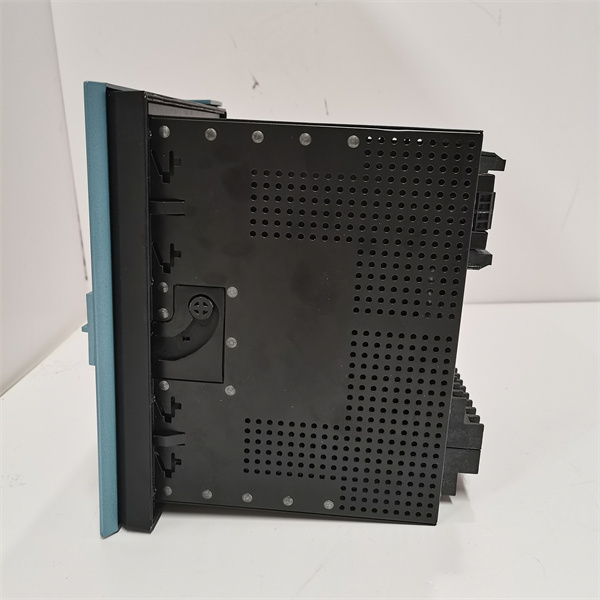

| Dimensions | Not provided (standard for panel or 19″ rack mount) |

| Weight | Shipping weight – 7.7 kg (17 lbs) |

| Warranty | 12 months |

| Certifications | Complies with UL 508 production tests |

| Mounting | Panel or 19″ rack mount |

GE SR489-P1-HI-A20-E

Product Introduction

The GE SR489 – P1 – HI – A20 – E is an advanced generator management relay from GE. Engineered to meet the complex demands of modern power generation systems, it serves as a critical component in ensuring the reliable operation of generators. This relay integrates a wide range of functions, including protection, control, and monitoring, making it a comprehensive solution for generator management. Its enhanced display (E) provides clear and detailed information, while its multiple input and output options allow for seamless integration into various power generation setups.

Core Advantages and Technical Highlights

Comprehensive Protection Suite: The SR489 – P1 – HI – A20 – E offers an extensive array of protection functions. Overcurrent protection safeguards the generator from excessive current flow, which could be caused by short circuits or sudden overloads in the connected electrical systems. Undervoltage protection prevents damage to the generator when the voltage drops below safe levels, while over / under frequency protection monitors and protects against deviations in the power system frequency. Loss of excitation protection is crucial for generators as it detects when the generator loses its excitation, which can lead to unstable operation and potential damage. Reverse power protection is another vital feature, ensuring that power does not flow back into the generator from the grid or other sources, protecting both the generator and the power network. For example, in a power generation plant during a sudden grid disturbance, if the frequency of the power system drops rapidly, the over / under frequency protection of the SR489 – P1 – HI – A20 – E will quickly detect the deviation and take appropriate action, such as reducing the generator’s output or even shutting it down to prevent damage.

Precise Control Capabilities: This relay provides precise control over generator starting, stopping, and synchronization processes. During generator startup, it ensures that the generator reaches its operating speed and voltage smoothly, minimizing stress on the generator’s components. When it comes to stopping the generator, the SR489 – P1 – HI – A20 – E executes the shutdown sequence in a controlled manner, protecting the generator from sudden electrical and mechanical shocks. In terms of synchronization, it accurately matches the generator’s frequency, voltage, and phase angle with the grid or other power sources, enabling a seamless connection. In a large – scale wind farm, the relay’s precise control capabilities are used to synchronize multiple wind turbine – driven generators to the grid, ensuring stable power injection into the grid.

Self – Diagnostic and Monitoring: Equipped with self – diagnostic capabilities, the SR489 – P1 – HI – A20 – E continuously monitors its own health. It can detect internal faults, such as component failures or communication errors, and provide diagnostic information for easy troubleshooting. This not only reduces downtime but also helps in proactive maintenance. Additionally, it monitors various generator parameters in real – time, such as current, voltage, power, and temperature. By analyzing these data, operators can gain insights into the generator’s performance and identify potential issues before they escalate. In a power plant’s control room, operators can rely on the relay’s self – diagnostic and monitoring features to quickly identify and resolve any problems with the generators, ensuring continuous power generation.

Flexible Communication and Customization: The relay supports multiple communication protocols, which allows for easy integration with supervisory control and data acquisition (SCADA) systems, as well as other intelligent devices in the power network. This enables remote monitoring and control of the generator, improving operational efficiency. Moreover, it offers customizable settings, allowing users to configure the relay according to the specific requirements of their power generation applications. Whether it’s a small – scale backup generator in a commercial building or a large – capacity generator in a power utility, the SR489 – P1 – HI – A20 – E can be tailored to provide the most suitable protection and control functions.

Typical Application Scenarios

Power Generation Plants: In traditional thermal power plants, hydroelectric power plants, and even nuclear power plants, the SR489 – P1 – HI – A20 – E is used to manage and protect the main generators. It ensures the stable operation of these high – capacity generators, protecting them from various electrical faults and providing precise control during startup, operation, and shutdown. In a coal – fired power plant, the relay controls the starting sequence of the large – scale steam – turbine – driven generator, monitors its performance during operation, and protects it from overcurrent and other faults.

Renewable Energy Installations: Wind farms and solar power plants also benefit from the SR489 – P1 – HI – A20 – E. In wind farms, it synchronizes the power generated by multiple wind turbines to the grid, protects the generators in the turbines from electrical faults, and controls their operation based on wind speed and grid conditions. In solar power plants, the relay manages the inverters that convert DC power from solar panels into AC power, ensuring stable power output and protecting the equipment from voltage and frequency fluctuations.

Industrial and Commercial Backup Power Systems: Many industrial facilities and commercial buildings rely on backup generators for power during grid outages. The SR489 – P1 – HI – A20 – E is used to manage these backup generators, ensuring they start up quickly and smoothly when needed, protect them from overloading during operation, and synchronize them with the building’s electrical system. In a hospital, for example, the backup generator, controlled by this relay, provides critical power during a power outage, ensuring the continuous operation of life – support systems and other essential medical equipment.

GE SR489-P1-HI-A20-E

Related Model Recommendations

GE SR489 – P2 – LO – A10 – S: This model may have different current input ratings (P2) and lower control power range (LO), along with different analog output capabilities (A10). It can be a suitable alternative for applications where the power requirements and monitoring needs are different from those of the SR489 – P1 – HI – A20 – E. In a small – scale off – grid power system with lower power demands, the SR489 – P2 – LO – A10 – S can provide cost – effective generator management.

GE Communication Gateway for SR489 Series: This dedicated communication gateway can enhance the communication capabilities of the SR489 – P1 – HI – A20 – E. It can support more complex communication protocols, enabling better integration with advanced SCADA systems or cloud – based monitoring platforms. In a large – scale power utility network with a need for centralized data management and advanced analytics, the communication gateway can help in collecting and analyzing data from multiple SR489 – series relays, improving the overall grid management.

GE Generator Monitoring Software: This software is designed to work in tandem with the SR489 – P1 – HI – A20 – E. It provides a more user – friendly interface for monitoring and analyzing the generator’s performance data. Operators can use this software to view real – time trends, generate reports, and set up alerts for abnormal conditions. In a power plant’s control center, the generator monitoring software allows operators to efficiently manage multiple generators equipped with SR489 – series relays, optimizing the power generation process.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installation, ensure that the power supply to the generator and related circuits is disconnected to avoid electrical hazards. Verify that the installation location is clean, dry, and free from excessive vibration and electromagnetic interference. Check that the control power supply voltage falls within the HI range (90 – 300 VDC / 70 – 265 VAC at 48 – 62 Hz). Select an appropriate mounting option, either panel or 19″ rack mount, and use the provided hardware to securely install the relay. Leave sufficient clearance around the relay for ventilation and easy access for future maintenance.

Commissioning: After installation, carefully connect the current transformers (CTs) and voltage transformers (VTs) to the relay’s input terminals according to the detailed wiring diagram provided in the product documentation. Connect the analog output cables to the appropriate devices. Power on the control supply and use the enhanced LCD display to configure the relay’s parameters. Set the protection thresholds, control settings, communication protocols, and other relevant parameters according to the requirements of the power generation system. Conduct comprehensive functional tests for each protection and control function by simulating various operating conditions, such as starting the generator, applying load, and introducing faults. Verify that the relay operates correctly and sends out appropriate signals. Check the communication links to ensure data is transmitted accurately to the connected monitoring systems.

Maintenance Suggestions: Regularly conduct visual inspections of the relay to check for any signs of loose connections, dust accumulation, or physical damage. Clean the relay’s exterior and ventilation slots periodically using compressed air to maintain proper cooling and prevent the ingress of dust and debris. Periodically verify the accuracy of the relay’s measurements by comparing its readings with calibrated test equipment. Review the self – diagnostic reports and fault records stored in the relay to identify any recurring issues or potential problems. Ensure that the relay’s firmware is kept up – to – date by checking GE’s official website for the latest software updates. In case of a fault or malfunction, refer to the detailed user manual or contact GE’s technical support team for prompt troubleshooting and resolution.

Service and Guarantee Commitment

GE offers a 12 – month warranty for the SR489 – P1 – HI – A20 – E, which covers manufacturing defects and component failures under normal operating conditions. The company’s global technical support team is available to provide assistance with installation, commissioning, and troubleshooting. Customers can access a wealth of resources, including detailed user manuals, technical specifications, and software updates, through GE’s online portal. For critical applications, GE may also offer extended warranty options and on – site service agreements to ensure the relay’s optimal performance and minimize downtime. In the event of a warranty claim, GE will promptly arrange for the repair or replacement of the faulty unit, ensuring customer satisfaction and the continuous, reliable operation of the generator management system.