Description

Detailed Parameter Table

| Parameter name | Parameter value |

| Product model | SR489-P1-HI-A20-E |

| Manufacturer | GE (General Electric) |

| Product category | Industrial Programmable Logic Controller (PLC) Module |

| Processor | High-performance 32-bit RISC processor with fast execution speed |

| Memory | 128 MB RAM for program and data storage, expandable up to 512 MB |

| I/O Capacity | Supports up to 2048 digital I/O points and 256 analog I/O points via expansion modules |

| Communication Ports | 2 x Ethernet ports (10/100/1000 Mbps), 2 x RS485 serial ports, 1 x USB port |

| Communication Protocols | Modbus TCP/IP, Ethernet/IP, Profibus DP, DeviceNet for seamless system integration |

| Operating Temperature | -20°C to +60°C, suitable for harsh industrial environments |

| Power Supply | 24 VDC ±10%, with power consumption of max 15 W |

| Mounting | DIN rail or panel mounting for flexible installation in control cabinets |

| Protection Rating | IP20 for the module, IP65 when installed in a sealed enclosure |

| Programming Software | Compatible with GE Proficy Machine Edition for intuitive programming |

| Certification | UL, CE, ATEX, IECEx compliant for use in hazardous and industrial areas |

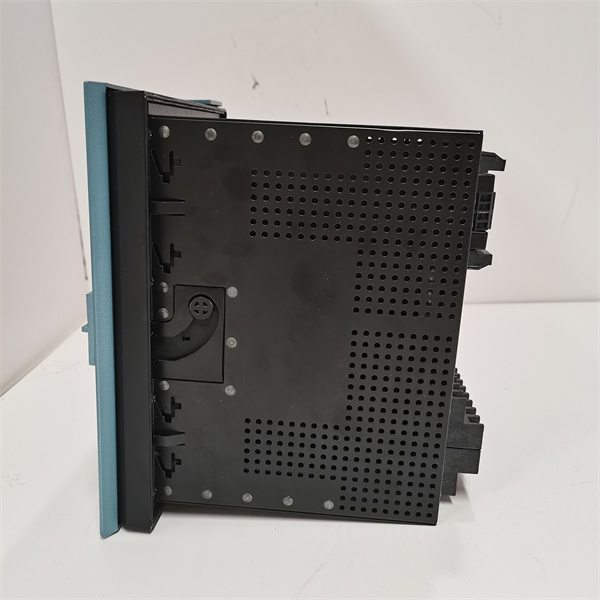

GE SR489-P1-HI-A20-E

Product Introduction

GE’s SR489-P1-HI-A20-E is a high-performance programmable logic controller module, designed to meet the demanding requirements of modern industrial automation systems. As a key member of GE’s SR series, it integrates advanced processing capabilities with extensive connectivity options, making it a versatile solution for complex control tasks.

The SR489-P1-HI-A20-E serves as the core of industrial control systems, executing user-defined logic to monitor and control machinery, processes, and equipment. Its powerful 32-bit RISC processor ensures rapid execution of control programs, while its expandable memory allows for handling large-scale applications. Whether in manufacturing, energy, or infrastructure sectors, this module enables precise control, real-time data acquisition, and seamless communication with other system components, enhancing overall operational efficiency.

Core Advantages and Technical Highlights

High-speed processing: The 32-bit RISC processor in the SR489-P1-HI-A20-E delivers exceptional execution speeds, with a program scan time of less than 1 ms for 10,000 instructions. This ensures quick response to dynamic process changes, critical in high-speed production lines such as automotive assembly, where split-second decisions can prevent costly errors.

Extensive connectivity: Equipped with multiple communication ports and support for various protocols, the SR489-P1-HI-A20-E easily integrates with SCADA systems, HMIs, and other industrial devices. For example, in a smart factory, it can communicate via Ethernet/IP with vision systems to adjust robotic movements based on real-time quality checks, or use Modbus TCP/IP to share data with energy management systems for optimized power usage.

Robust reliability: Designed to operate in -20°C to +60°C, the SR489-P1-HI-A20-E withstands extreme temperatures, vibrations, and electrical noise common in industrial settings. Its rugged construction and compliance with hazardous area certifications make it suitable for oil refineries, chemical plants, and mining operations, where equipment reliability is paramount.

Scalable performance: With support for up to 2048 digital I/O and 256 analog I/O points, the SR489-P1-HI-A20-E grows with system demands. Users can add expansion modules without replacing the core controller, reducing upgrade costs. In a water treatment plant, this scalability allows for adding new sensor arrays or control valves as the facility expands.

Typical Application Scenarios

In large-scale manufacturing facilities, the SR489-P1-HI-A20-E controls automated production lines, coordinating conveyor belts, robotic arms, and packaging machines. It monitors input signals from proximity sensors (detecting part presence) and uses output signals to adjust motor speeds or activate grippers, ensuring precise synchronization of production steps and minimizing downtime.

In renewable energy plants, such as solar farms, the SR489-P1-HI-A20-E manages inverter systems and trackers. It collects data from irradiance sensors and weather stations via analog inputs, then adjusts tracker angles through output signals to maximize sunlight capture. Its Ethernet connectivity enables remote monitoring and control, allowing operators to optimize energy production from a central location.

In municipal infrastructure, like wastewater treatment plants, the module regulates pumps, valves, and aeration systems. It uses digital inputs to monitor flow meters and level sensors, executing logic to switch pumps on/off based on water levels. The SR489-P1-HI-A20-E also communicates with SCADA systems to log process data, supporting compliance with environmental regulations and enabling predictive maintenance of equipment.

GE SR489-P1-HI-A20-E

Related Model Recommendations

SR489-P2-HI-A20-E: A higher-performance variant of the SR489-P1-HI-A20-E with a faster processor and increased memory (up to 1 GB), ideal for large-scale applications requiring complex control logic, such as integrated steel mills.

SR469-P1-HI-A10-E: A compact version with reduced I/O capacity, suitable for small to medium-sized systems like packaging machines or standalone industrial ovens. It shares the same programming software as the SR489-P1-HI-A20-E for consistency.

IC693CPU374: A PLC processor from GE’s 90-30 series, compatible with the SR489-P1-HI-A20-E in hybrid systems. It handles legacy I/O modules, facilitating migration from older control systems.

SR489-IO-8D8A: A digital/analog I/O expansion module that pairs with the SR489-P1-HI-A20-E, adding 8 digital inputs, 8 digital outputs, and 4 analog inputs for enhanced sensing and control capabilities.

SR489-COM-ETH: An advanced communication module that extends the SR489-P1-HI-A20-E‘s connectivity with additional Ethernet ports and support for OPC UA, enabling integration with cloud-based analytics platforms.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Mount the SR489-P1-HI-A20-E on a clean DIN rail or panel in a control cabinet with adequate ventilation. Ensure the ambient temperature remains within -20°C to +60°C and avoid direct exposure to moisture or corrosive gases. Verify the 24 VDC power supply is stable and properly fused (1 A recommended). Use shielded cables for communication and I/O connections to reduce EMI, and ground the module per GE specifications.

Maintenance suggestions: Inspect the SR489-P1-HI-A20-E quarterly for loose connections or dust accumulation, cleaning with compressed air if necessary. Back up the program regularly using Proficy Machine Edition to prevent data loss. Monitor processor load and memory usage via the HMI; values exceeding 80% may indicate the need for optimization or expansion. In case of faults, check error codes in the module’s diagnostic buffer—common issues like communication timeouts can often be resolved by verifying network settings or cable integrity. Replace faulty components with genuine GE parts to maintain performance and warranty coverage.

Service and Guarantee Commitment

GE provides a 3-year standard warranty for the SR489-P1-HI-A20-E, covering manufacturing defects and performance issues. Their global technical support team offers 24/7 assistance via online portals, email, and phone, providing programming guidance, troubleshooting help, and firmware updates. For critical applications, GE engineers can perform on-site commissioning to ensure optimal configuration and integration.

Extended warranty options (up to 7 years) and preventive maintenance contracts are available, including periodic health checks and software upgrades. Customers also gain access to GE’s training programs, both online and in-person, to enhance user proficiency with the SR489-P1-HI-A20-E. This comprehensive support ensures reliable operation and maximizes the module’s lifespan, delivering long-term value for industrial automation investments.