Description

Product Overview

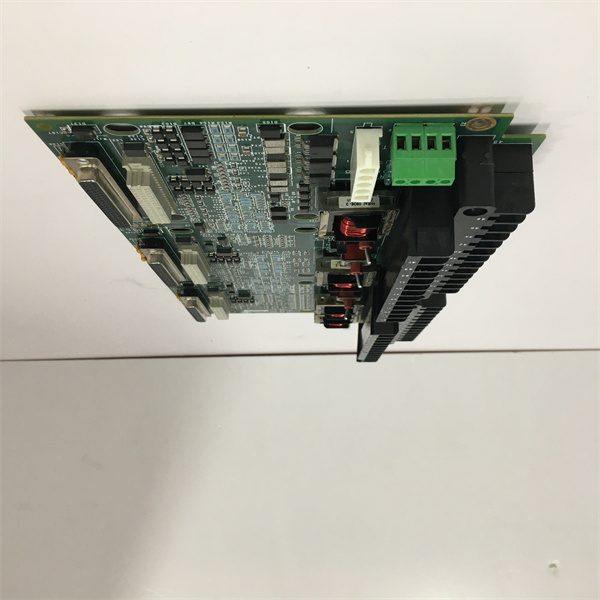

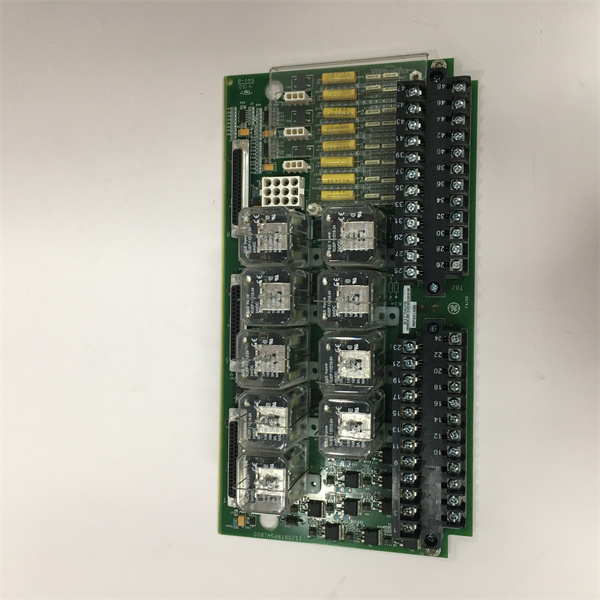

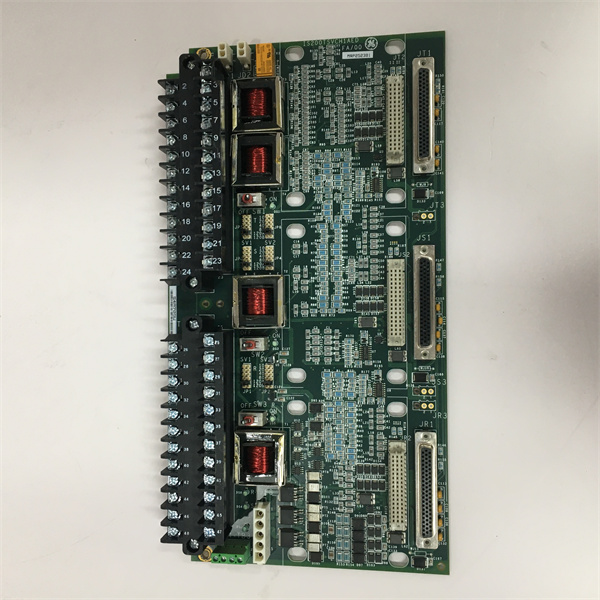

The GE T30 – 04E by General Electric is a high – performance industrial control module, designed to play a pivotal role in various industrial automation setups. It belongs to GE’s line of advanced control solutions, offering a seamless blend of precision and reliability. This module is engineered to precisely monitor and control industrial processes, making it an essential component in modern industrial environments.

With 4 analog input and 4 analog output channels, the GE T30 – 04E can interface with a wide range of sensors and actuators. It is well – suited for applications that demand accurate handling of analog signals, such as in manufacturing plants, power generation facilities, and process automation systems. The module’s design focuses on providing stable operation, ensuring that industrial operations can run smoothly without interruptions. It serves as a reliable link in the automation chain, enabling effective communication and control between different parts of an industrial system.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | T30 – 04E |

| Manufacturer | General Electric |

| Product Type | Control Module |

| Input Channels | 4 analog inputs |

| Output Channels | 4 analog outputs |

| Operating Voltage | 24 VDC |

| Power Consumption | 5 W |

| Communication Interface | Ethernet, RS485 |

| Operating Temperature Range | – 40 °C to 85 °C |

| Humidity Range | 0% to 95%, non – condensing |

| Dimensions | 100 mm x 100mm x 50 mm |

| Weight | 0.5 kg |

| Certifications | CE, UL, ATEX |

Main Features and Advantages

Robust Performance

The GE T30 – 04E is built to endure harsh industrial conditions. Its wide operating temperature range from – 40 °C to 85 °C ensures it can function optimally in environments with extreme temperature variations, like those found in steel mills or outdoor power generation stations. This resilience reduces the risk of system failures due to temperature – related issues.

Precise Signal Handling

Equipped with 4 analog input and output channels, it can accurately process and transmit analog signals. This precision is crucial in applications where even slight signal inaccuracies can lead to significant operational problems, such as in chemical processing plants where precise control of flow rates or temperature is essential.

Easy Connectivity

Featuring Ethernet and RS485 communication interfaces, the GE T30 – 04E enables seamless integration with other devices and systems within the industrial network. This ease of connectivity allows for efficient data exchange, facilitating real – time monitoring and control. It can communicate with programmable logic controllers (PLCs), human – machine interfaces (HMIs), and other industrial control components, enhancing the overall functionality of the automation system.

IS200TSVCH1AED

Application Field

In power generation plants, the GE T30 – 04E is used to monitor and control various parameters such as voltage, current, and temperature of generators and associated equipment. It helps in maintaining stable power output and ensuring the efficient operation of the power generation process.

Manufacturing industries also benefit greatly from this module. In automated production lines, it can control the speed and operation of motors, adjust the position of robotic arms, and manage the flow of materials. For example, in an automotive assembly plant, it can precisely control the movement of conveyor belts and the operation of welding robots, improving production efficiency and product quality.

In the process automation sector, especially in chemical and food processing industries, the GE T30 – 04E plays a vital role. It can regulate the flow of fluids, control the temperature and pressure in reactors, and monitor the quality of products during the manufacturing process. This ensures that the production process adheres to strict quality standards and safety regulations.

Related Products

- GE T30 – 02E: A lower – end variant of the GE T30 – 04E with fewer input and output channels. It is suitable for smaller – scale industrial applications where the complexity and the number of connected devices are limited.

- GE T30 – 06E: An upgraded model with enhanced processing capabilities and more input/output channels. It is designed for larger and more complex industrial setups that require higher – performance control modules.

- GE T30 – 04E – R: A redundant version of the GE T30 – 04E, which incorporates backup components. This is ideal for applications where high availability is critical, such as in aerospace manufacturing or nuclear power plants, as it minimizes the risk of system failures.

- GE T30 – 04E – X: This version has an extended temperature range compared to the standard GE T30 – 04E, making it suitable for even more extreme environmental conditions, like in oil and gas exploration in arctic regions.

- GE T30 – 04E – C: It comes with additional communication options, supporting more communication protocols. This is beneficial for industrial networks with diverse communication requirements, allowing for better integration with a wider range of devices.

Installation and Maintenance

Pre – installation preparation: Before installing the GE T30 – 04E, ensure that the installation area is clean and free from dust and moisture. Check the power supply to confirm it is a stable 24 VDC. Verify the integrity of the Ethernet and RS485 cables that will be used for connectivity. The module should be installed in a location where it is easily accessible for future maintenance. Mount it securely in the designated control panel, following the provided installation guidelines.

Maintenance recommendations: Regularly inspect the GE T30 – 04E for any signs of physical damage, such as cracks in the casing or loose connections. Monitor its operating temperature and ensure it remains within the specified range. Clean the module periodically to prevent dust build – up, as excessive dust can affect its performance. Check the communication interfaces for any signs of communication errors. If any issues are detected, refer to the product manual for troubleshooting steps or contact GE’s technical support.

Product Guarantee

GE stands firmly behind the quality of the GE T30 – 04E. The module undergoes rigorous quality – control procedures during manufacturing to meet high – industry standards. GE offers a comprehensive warranty, typically covering manufacturing defects for a specified period. In case of any quality – related issues within the warranty period, GE’s global technical support team is readily available. They can provide detailed guidance on installation, troubleshooting, and, if necessary, arrange for the repair or replacement of the GE T30 – 04E. This reflects GE’s commitment to customer satisfaction and the long – term reliability of the product in industrial applications.