Description

Product Overview

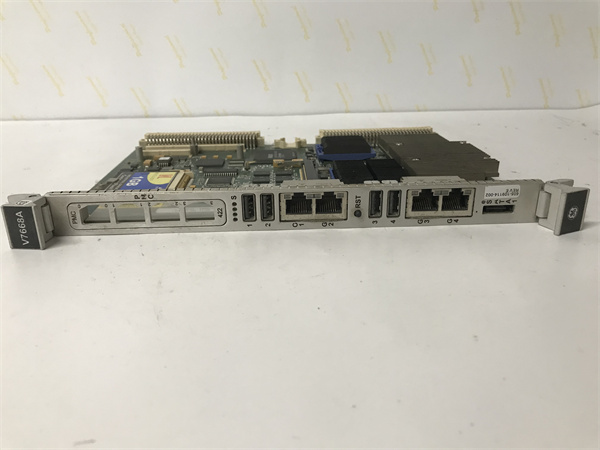

The GE V7668A – 131000 350 – 9310007668 – 131000 B is a high – performance control module engineered by General Electric, tailored for industrial automation applications. This module serves as a crucial component in various industrial setups, enabling seamless communication and control within automated systems. With its advanced design, it offers reliable performance and precise control capabilities, making it an ideal choice for industries where accuracy and consistency are key. Whether it’s managing complex industrial processes or integrating with existing systems, the GE V7668A – 131000 350 – 9310007668 – 131000 B plays a vital role in enhancing overall system efficiency. It’s designed to handle the rigors of industrial environments, ensuring long – term stable operation.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | V7668A – 131000 350 – 9310007668 – 131000 B |

| Manufacturer | General Electric |

| Product Type | Control Module |

| Input Channels | 8 |

| Resolution | 12 – bit |

| Voltage Range | ± 10 V |

| Current Range | ± 20 mA |

| Operating Temperature | – 40 °C to + 85 °C |

| Weight | 0.35 kg |

| Dimensions | 10 cm x 15 cm x 5 cm |

| Communication Interface | Multiple (e.g., serial, Ethernet for potential data transfer) |

| Input Voltage | 24 VDC (common industrial standard for power input) |

| Output Voltage | 24 VDC (suitable for powering connected devices) |

| Current Rating | 1 A (adequate for driving various loads) |

| Certifications | CE, UL, ISO 9001 (meeting international quality and safety standards) |

GE V7668A-1310B0 350-9310007668-131020 B

GE V7668A-1310B0 350-9310007668-131020 B(4)

Main Features and Advantages

Robust Design for Harsh Environments

The GE V7668A – 131000 350 – 9310007668 – 131000 B is constructed to endure harsh industrial conditions. With an operating temperature range from – 40 °C to + 85 °C, it can function optimally in environments with extreme temperature variations. Its compact design, measuring 10 cm x 15 cm x 5 cm and weighing 0.35 kg, allows for easy integration into existing installations without taking up excessive space.

Precise Control and Monitoring

Featuring 8 input channels with a 12 – bit resolution, this module can accurately detect and process signals. The ± 10 V voltage range and ± 20 mA current range enable it to interface with a wide variety of sensors and actuators. This precision in measurement and control is crucial for maintaining the quality and efficiency of industrial processes.

Reliable Communication and Compatibility

It comes with multiple communication interfaces, facilitating seamless data transfer between different devices in the industrial network. Whether it’s sending control commands or receiving feedback from sensors, the module ensures smooth communication. Also, being compliant with international certifications like CE, UL, and ISO 9001, it guarantees reliable and safe operation in diverse industrial applications.

Application Field

Manufacturing Industry

In manufacturing plants, the GE V7668A – 131000 350 – 9310007668 – 131000 B can be used to control conveyor systems. By precisely regulating the speed and movement of conveyors, it helps in optimizing the production flow. For example, in an automotive manufacturing assembly line, it can ensure that parts are delivered to the right stations at the right time, enhancing overall productivity.

Power Generation

In power plants, this module is useful for monitoring and controlling various parameters. It can be connected to sensors that measure temperature, pressure, and flow rate in steam turbines or gas turbines. Based on the received data, it can adjust the operation of the turbines to maintain stable power generation. This helps in improving the efficiency of power plants and reducing downtime.

Process Industries

Industries such as chemical and petrochemical rely on precise control of processes. The GE V7668A – 131000 350 – 9310007668 – 131000 B can control the opening and closing of valves, regulate the speed of pumps, and monitor chemical reactions. In a chemical plant, it can ensure that the correct amount of reactants are mixed at the right temperature and pressure, leading to consistent product quality.

Related Products

- GE V7668A – 1310B0 350 – 9310007668 – 131020: A similar control module, perhaps with differences in input/output configurations or communication protocols. It might be designed for specific applications that require a different set of features compared to the GE V7668A – 131000 350 – 9310007668 – 131000 B.

- GE IS410TRLYS1B: A relay output terminal board. While the GE V7668A – 131000 350 – 9310007668 – 131000 B focuses on overall control and monitoring, the IS410TRLYS1B is more about relaying electrical signals. However, they can work together in a complex industrial control system.

- GE IC693CPU341: A CPU module. It provides the processing power for industrial control systems. The GE V7668A – 131000 350 – 9310007668 – 131000 B can interface with this CPU module to execute control algorithms and manage data flow.

- GE DS200SDCCG1AEC: A drive control card. It is mainly used in turbine control systems. In some industrial setups, the GE V7668A – 131000 350 – 9310007668 – 131000 B might be used in conjunction with the DS200SDCCG1AEC to provide additional control and monitoring functions for turbine – related operations.

- GE IS415UCVGH1A: A VME controller card. It can be part of a larger industrial control network where the GE V7668A – 131000 350 – 9310007668 – 131000 B also operates. They can collaborate to manage different aspects of industrial processes, such as data processing and signal control.

Installation and Maintenance

Pre – installation preparation: Before installing the GE V7668A – 131000 350 – 9310007668 – 131000 B, ensure that the installation area is clean and free from dust and debris. Verify that the power supply voltage matches the module’s requirement of 24 VDC. Check the compatibility of the module with other components in the system, especially in terms of communication interfaces. Make sure the ambient temperature at the installation site is within the operating range of – 40 °C to + 85 °C.

Maintenance recommendations: Regularly inspect the GE V7668A – 131000 350 – 9310007668 – 131000 B for any signs of physical damage, such as cracks or loose connections. Monitor the input and output signals to ensure they are within the expected range. Clean the module periodically to prevent dust accumulation, which could affect its performance. In case of any malfunction, refer to the product manual for troubleshooting steps or contact GE’s technical support for assistance.

Maintenance recommendations: Regularly inspect the GE V7668A – 131000 350 – 9310007668 – 131000 B for any signs of physical damage, such as cracks or loose connections. Monitor the input and output signals to ensure they are within the expected range. Clean the module periodically to prevent dust accumulation, which could affect its performance. In case of any malfunction, refer to the product manual for troubleshooting steps or contact GE’s technical support for assistance.

Product Guarantee

General Electric stands firmly behind the GE V7668A – 131000 350 – 9310007668 – 131000 B with a comprehensive product guarantee. The module is manufactured using high – quality materials and advanced manufacturing techniques, ensuring its reliability. GE offers a standard warranty period, during which any defects in materials or workmanship will be rectified at no cost to the customer. Their team of technical experts is available to provide support for installation, configuration, and troubleshooting. In case of any issues with the GE V7668A – 131000 350 – 9310007668 – 131000 B, customers can reach out to GE’s customer service, who will work promptly to resolve the problem. This commitment reflects GE’s confidence in the quality of the product and its dedication to providing a seamless experience for industrial users.