Description

Parameter table

| Parameter name | Parameter value |

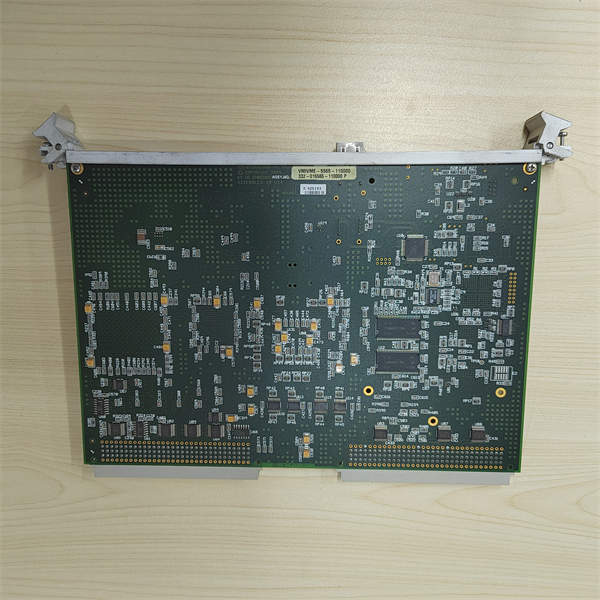

| Product model | VME5565 VMIVME-5565-11000 332-015565-110000 P |

| Manufacturer | General Electric (GE) |

| Product category | VMEbus-based Industrial Control Module |

| Dimensions (approx.) | Compliant with VMEbus standard dimensions, compact for easy integration into VME chassis; specific sizes in product manual |

| Weight | Lightweight, suitable for installation in industrial control cabinets with limited space |

| Processor | High-performance multi-core industrial processor, optimized for real-time control and data processing |

| Memory | Large-capacity memory configuration, including DDR4 SDRAM for high-speed data operation and flash memory for program and data storage |

| I/O interfaces | Multiple VMEbus-compliant I/O ports, supporting connection with various VME peripheral modules (digital I/O, analog I/O, etc.) |

| Communication protocols | Supports VMEbus protocol, and optional Ethernet, RS-485 and other communication interfaces for system expansion |

| Power supply | +5V DC, +12V DC, with overvoltage, overcurrent protection functions to ensure stable operation |

| Operating temperature range | -40°C to +85°C, adapting to more extreme industrial environments |

| Environmental resistance | Strong resistance to vibration (complying with IEC 60068-2-6 standard), shock (complying with IEC 60068-2-27 standard), and electromagnetic interference |

| Expansion capability | Equipped with multiple expansion slots, supporting the addition of specialized function modules (such as high-speed data acquisition cards) |

| Diagnostic functions | Advanced self-diagnostic system, with LED indicators for power, communication, and fault status, supporting remote diagnosis via software |

GE VME5565 VMIVME-5565-11000 332-015565-110000 P

Product introduction

The GE VME5565 VMIVME-5565-11000 332-015565-110000 P is a high-performance VMEbus-based industrial control module, which is an important part of GE’s industrial automation product line. It is designed to meet the high requirements of complex industrial control systems for processing capacity, reliability, and environmental adaptability.

This module acts as a core controller in VMEbus systems, responsible for receiving real-time data from various sensors and field devices, processing it through pre-programmed control algorithms, and sending control commands to actuators and execution components. It can coordinate the operation of multiple peripheral modules to realize precise control and monitoring of industrial processes.

With its powerful performance and rugged design, the VME5565 is widely used in key industrial fields such as aerospace, defense, energy, and heavy industry. It is suitable for applications requiring high real-time performance, high reliability, and operation in harsh environments, such as control systems of large-scale industrial equipment, test benches, and on-site monitoring systems.

Core advantages and technical highlights

Superior processing performance: Equipped with a high-performance multi-core industrial processor, the VME5565 can handle complex control logic and massive data processing tasks at high speed. Its multi-core architecture allows parallel processing of multiple tasks, ensuring that each control loop and data acquisition task can be completed within the specified time. For example, in a large-scale wind turbine control system, it can simultaneously process data from hundreds of sensors (such as wind speed, rotation speed, and vibration), and quickly calculate the optimal pitch angle and yaw direction to maximize power generation efficiency.

Extreme environmental adaptability: With an operating temperature range of -40°C to +85°C, the module can work stably in extremely cold areas such as polar regions and high-temperature industrial sites such as steel plants. Its excellent vibration and shock resistance enable it to adapt to the harsh working environment of mobile equipment (such as engineering machinery and ships). In the field of oil drilling, it can withstand the strong vibration of drilling platforms and the high temperature and humidity environment underground, ensuring the continuous operation of the drilling control system.

Rich I/O and expansion capabilities: The module is equipped with multiple VMEbus-compliant I/O interfaces, which can be flexibly connected with various peripheral modules to form a customized control system. The expansion slots allow users to add specialized function modules according to actual needs, such as high-speed A/D conversion cards for precision measurement or communication modules supporting special protocols. This scalability makes the VME5565 applicable to both small-scale control systems and large-scale distributed control networks.

Advanced diagnostic and fault-tolerant functions: The advanced self-diagnostic system can monitor the working status of the module in real time, including processor operation, memory status, and communication links. Once a fault is detected, it can send an alarm signal immediately and record the fault information. The LED indicators on the panel can 直观地 display the fault type, which is convenient for maintenance personnel to quickly locate the problem. In some critical applications, it can support hot swapping and redundant configuration, ensuring that the system can continue to operate without interruption when a single module fails.

Strong compatibility and integration: As a standard VMEbus module, it has good compatibility with other VMEbus devices from different manufacturers, facilitating users to upgrade and expand existing systems. It can seamlessly integrate with GE’s industrial software platforms (such as Proficy) to realize functions such as data visualization, remote monitoring, and predictive maintenance. In a smart factory, it can upload real-time production data to the cloud platform through the Ethernet interface, providing a data basis for enterprise decision-making.

Typical application scenarios

Aerospace test and control: In aerospace ground test systems (such as aircraft engine test benches and missile launch test systems), the VME5565 is used as the core controller to coordinate multiple test equipment. It can collect data from high-precision sensors (such as pressure, temperature, and thrust) at a high speed, control the operation of test benches (such as adjusting fuel flow and air pressure), and record and analyze test data in real time. Its high real-time performance ensures that the test process can be accurately controlled according to the preset program, and the test data is accurate and reliable.

Energy industry control systems: In nuclear power plants, the module is used in the reactor control system and safety protection system. It can monitor key parameters such as reactor core temperature, pressure, and water level in real time, and control the operation of control rods and coolant pumps according to the preset safety logic. In case of abnormal conditions, it can quickly issue shutdown commands to ensure the safety of the reactor. Its high reliability and anti-interference ability are crucial for the safe operation of nuclear power plants.

Marine and offshore engineering: On offshore oil platforms and ships, the VME5565 is used to control navigation systems, power systems, and oil production equipment. It can withstand the harsh marine environment (high humidity, salt spray, and strong vibration) and ensure the stable operation of various systems. For example, on an offshore oil platform, it can control the operation of oil pumps and separators, monitor the pressure and flow of oil and gas pipelines, and coordinate with the weather monitoring system to take measures in advance when encountering severe weather.

Heavy industry production lines: In steel, non-ferrous metals, and other heavy industry production lines, the module is used to control rolling mills, smelting furnaces, and other key equipment. It can accurately control parameters such as temperature, pressure, and speed in the production process, ensuring product quality and production efficiency. In a steel rolling mill, it can control the rolling speed and pressure of the rolling mill according to the thickness requirements of the steel plate, and adjust in real time according to the feedback signal of the thickness sensor to ensure that the steel plate thickness meets the standard.

GE VME5565 VMIVME-5565-11000 332-015565-110000 P

Comparison with related models in the series

Compared with other GE VMEbus modules: Compared with low-end VMEbus modules (such as VMIVME-017807 series), the VME5565 has more powerful processing performance and a wider operating temperature range. The low-end modules are suitable for small-scale control systems with low real-time requirements, while the VME5565 is more suitable for large-scale, complex systems requiring high-speed data processing and operation in extreme environments. Compared with high-end VMEbus modules with redundant processors, the VME5565 has a more favorable price while meeting most critical application requirements. It provides a better cost-performance ratio for users who do not need full redundancy.

Compared with similar products from other brands: Compared with VMEbus modules from other manufacturers, the VME5565 has obvious advantages in environmental adaptability. Its operating temperature range of -40°C to +85°C is wider than that of many similar products, making it more competitive in extreme environment applications. In terms of software integration, it can better integrate with GE’s industrial software ecosystem, reducing the difficulty of system development and maintenance. In addition, GE’s global service network can provide timely technical support and after-sales service for users all over the world, which is an important guarantee for the stable operation of the system.

Installation, commissioning and maintenance instructions

Installation preparation: Before installation, ensure that the VME chassis is powered off and grounded reliably. Check that the dimensions of the installation position in the chassis match the module. Prepare tools such as screwdrivers, anti-static wristbands, and torque wrenches. Read the installation manual carefully to understand the wiring requirements and precautions. Check that the power supply parameters (voltage, current) meet the module’s requirements, and ensure that the power supply has overvoltage and overcurrent protection functions. Clean the installation position to avoid dust and debris affecting the module’s heat dissipation.

Commissioning process: Install the module into the VME chassis along the guide rail, ensuring that the connectors are fully inserted and fastened with screws. Connect the power cable, I/O cables, and communication cables according to the wiring diagram, and check that the connections are correct and firm. Power on the chassis and observe the LED indicators on the module: the power indicator should be on, and there should be no fault indicators. Use the configuration software (such as GE’s VME Configurator) to set the module’s parameters, including IP address, communication protocol, and I/O mapping. Run the test program to verify that the module can correctly receive input signals and send output commands. Simulate various fault conditions (such as disconnection of I/O cables) to check whether the diagnostic system can work normally. Record the commissioning data and configuration parameters for future reference.

Maintenance suggestions: Regularly inspect the module’s appearance, check for loose connectors, signs of overheating, or corrosion. Clean the dust on the module’s surface and heat sink regularly to ensure good heat dissipation. Monitor the module’s working status through the diagnostic software, pay attention to key parameters such as CPU usage and memory occupancy, and deal with abnormalities in time. Back up the module’s configuration data and program regularly to prevent data loss due to unexpected situations. When updating the firmware, strictly follow the manufacturer’s guidelines to avoid problems caused by improper operation. In case of a fault, first check the external connections and power supply according to the fault code indicated by the LED, and then replace the module or faulty components if necessary. Use genuine GE spare parts to ensure the module’s performance and reliability.

Service and guarantee commitment

GE provides a 3-year standard warranty for the VME5565 VMIVME-5565-11000 332-015565-110000 P, covering manufacturing defects and performance problems under normal use. The global technical support team provides 24/7 service through phone, email, and online platforms, providing users with professional technical advice and troubleshooting guidance. Users can obtain the latest technical documents, firmware updates, and application cases through GE’s official website and customer portal. For key customers and critical applications, GE can provide on-site technical support and training services to help users master the use and maintenance skills of the module. In addition, GE offers extended warranty services and preventive maintenance plans to further reduce the risk of system failure and ensure the long-term stable operation of the module.