Description

Detailed Parameter Table

| Parameter name | Parameter value |

| Product model | VMIVME – 1150 |

| Manufacturer | GE (General Electric) |

| Product category | 64 – bit Optically Coupled Digital Input Board |

| Input channels | 64 optically coupled digital inputs |

| Input voltage range | 5 to 48 VDC |

| Isolation | Sustained isolation voltage: 1 kV; Pulsed isolation voltage: 7.5 kV |

| Form factor | Double eurocard with front panel |

| Data transfer types | 8 – bit (D8) or 16 – bit (D16) |

| Access time | Maximum 250 ns |

| Data polarity | Positive true or negative true selectable |

| Input characteristics | Voltage sourcing or current sinking |

| Input options | Filtered input options, contact closure sensing |

| Interfaces and connectors | Dual I/O connectors, high – reliability DIN – compatible input connector |

| Operating temperature range | – 40 °C to + 85 °C |

| Humidity | 5% – 95% non – condensing |

| Vibration resistance | 5 g rms, 10 to 500 Hz |

| Shock resistance | 30 g, half – sine, 11 ms pulse |

| Mean Time Between Failures (MTBF) | > 100,000 hours |

| Power consumption | 5W |

| Warranty | 12 months |

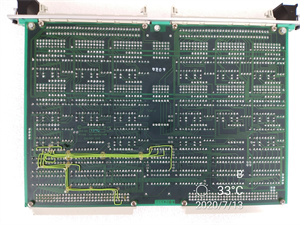

GE VMIVME-1150

Product Introduction

The GE VMIVME – 1150 is a high – performance 64 – bit optically coupled digital input board meticulously designed and optimized for VMEbus – based systems. This board showcases GE’s commitment to delivering reliable and efficient solutions for industrial applications. By leveraging optical isolation technology, it offers enhanced protection against electrical noise and interference, making it an ideal choice for environments where accurate digital signal input is crucial.

Core Advantages and Technical Highlights

High – density digital input channels: With 64 optically coupled digital inputs, the VMIVME – 1150 can interface with a large number of digital sensors simultaneously. This high – density input configuration is particularly useful in industrial settings where multiple sensors are used for monitoring various parameters. For example, in a manufacturing plant, it can connect to limit switches, proximity sensors, and temperature sensors that provide digital output signals. The board’s ability to handle a significant number of inputs streamlines the data acquisition process and reduces the need for multiple input boards, thus simplifying system design and reducing costs.

Wide input voltage range: Supporting an input voltage range from 5 to 48 VDC, the VMIVME – 1150 can accommodate a diverse range of digital sensors. This flexibility in input voltage makes it compatible with different types of industrial sensors, whether they are low – voltage transducers or higher – voltage devices. It eliminates the need for additional voltage conversion circuitry in many cases, further enhancing the board’s usability and cost – effectiveness.

Exceptional isolation capabilities: The board features high – level optical isolation, with a sustained isolation voltage of 1 kV and a pulsed isolation voltage of 7.5 kV. This isolation effectively protects the board and connected equipment from electrical noise, ground loops, and voltage transients. In electrically noisy industrial environments, this isolation ensures stable and accurate digital signal reception, reducing the likelihood of false readings or system malfunctions. It also helps to safeguard the board from damage due to electrical surges, increasing the overall reliability and lifespan of the system.

Flexible data transfer options: The VMIVME – 1150 supports both 8 – bit and 16 – bit data transfers, providing users with the flexibility to interface with different types of digital systems. This adaptability allows for seamless integration with a wide range of VMEbus – based controllers and processors. Whether the connected system requires 8 – bit data for simple control applications or 16 – bit data for more complex data processing, the board can meet the requirements without the need for additional data conversion hardware.

Filtered input options and contact closure sensing: The board offers filtered input options, which help to eliminate high – frequency noise from the input signals. This is especially important in industrial environments where electrical interference can be a significant issue. Additionally, it has contact closure sensing capabilities, allowing it to detect the open or closed state of switches or relays. This functionality is useful in applications such as monitoring the status of machinery components or controlling access to certain areas in a factory.

Typical Application Scenarios

Industrial control systems: In industrial control applications, the VMIVME – 1150 can be used to interface with a variety of digital sensors and switches. It can receive signals from limit switches that indicate the position of moving parts in machinery, proximity sensors that detect the presence of objects, and pressure switches that monitor the pressure levels in pipelines. Based on these input signals, the board can provide data to a central control system, which can then make decisions to control the operation of motors, valves, and other actuators. For example, in a conveyor belt system, the board can monitor the status of sensors that detect the presence of products on the belt and trigger the appropriate actions to ensure smooth product flow.

Test and measurement systems: In test and measurement setups, the VMIVME – 1150 can be used to acquire digital data from various test instruments. It can connect to digital multimeters, oscilloscopes, and signal generators that provide digital output signals. The board can then transfer this data to a computer or a data acquisition system for further analysis. For instance, in a quality control laboratory, it can be used to monitor the digital output of sensors during product testing, ensuring that the products meet the required specifications.

Machine vision systems: In machine vision applications, the VMIVME – 1150 can be used to interface with digital cameras and other vision – related sensors. It can receive digital signals from cameras that detect the presence, position, or orientation of objects. The board can also be used to control the operation of lighting systems and other peripherals in the machine vision setup. Based on the input signals, the board can provide data to a vision processing unit, which can then analyze the images and make decisions to control the manufacturing process. For example, in a semiconductor manufacturing plant, the board can be used to monitor the quality of semiconductor wafers by receiving digital signals from cameras that inspect the wafers for defects.

GE VMIVME-1150

Related Model Recommendations

GE VMIVME – 5576: The VMIVME – 5576 is a multifunction I/O board with analog and digital I/O capabilities. In some industrial applications, the VMIVME – 1150 can be used in combination with the VMIVME – 5576. While the VMIVME – 1150 focuses on digital input functions, the VMIVME – 5576 can handle analog input and output signals, as well as additional digital I/O tasks. For example, in a complex industrial control system, the VMIVME – 1150 can be used to receive digital input signals from sensors, and the VMIVME – 5576 can be used to generate analog output signals to control actuators.

GE VMIVME – 7698: The VMIVME – 7698 is a serial communication board. In certain industrial setups, the VMIVME – 1150 can work in tandem with the VMIVME – 7698. The VMIVME – 1150 can receive digital input signals from local sensors, and the VMIVME – 7698 can be used to communicate with remote devices via serial protocols. For instance, in a distributed industrial monitoring system, the VMIVME – 1150 can collect digital data from sensors in a local area, and the VMIVME – 7698 can transmit this data to a remote control center over a serial communication link.

GE D20ME – VME: This VME module can serve as a central processing or communication hub in a system where the VMIVME – 1150 is used for digital input functions. The D20ME – VME offers features such as multiple communication interfaces (RS – 232, RS – 485, Ethernet) and overcurrent protection. It can communicate with the VMIVME – 1150 over the VMEbus, enabling seamless integration of digital input data with other data acquisition, control, and communication functions in the system.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the VMIVME – 1150, ensure that the VMEbus backplane in which it will be installed is powered off. Use anti – static wristbands and other static – control measures to prevent electrostatic discharge (ESD) damage to the board. Check that the physical dimensions of the installation location are compatible with the board’s double eurocard form factor. Verify that the power supply in the system can meet the board’s 5W power consumption requirement. The circuit board address can be selected using the onboard DIP switch. Note that the board can run in any available slot on the VME bus backplane except for slot 1. There is also a jumper to support short supervised or non – privileged short I/O access options, and it is configured for short monitoring I/O access at the factory.

Commissioning: Once installed, power on the system. Use the appropriate software or control interface to configure the data transfer type (8 – bit or 16 – bit), data polarity, and input characteristics (voltage sourcing or current sinking) according to the requirements of the application. Test each input channel by connecting a known digital sensor and verifying that the board correctly reads the sensor’s output. Check for any signs of overheating or abnormal operation during the initial testing phase.

Maintenance suggestions: Regularly perform visual inspections of the VMIVME – 1150 for any signs of physical damage, such as bent pins or discolored components. Check for loose connections on the board and in the VMEbus backplane. Monitor the operating temperature of the board, especially in high – temperature environments, to ensure it remains within the specified – 40 °C to + 85 °C range. If any input channels fail to operate correctly, use diagnostic tools to check for electrical faults, such as short – circuits or open – circuits. Replace the board if any irreparable damage is detected. Given its high MTBF of > 100,000 hours, with proper maintenance, the board is expected to provide long – term reliable service.

Service and Guarantee Commitment

GE provides a 12 – month warranty for the VMIVME – 1150, covering manufacturing defects and component failures under normal operating conditions. Technical support is available through GE’s customer service channels, where trained technicians can assist with installation, troubleshooting, and any other technical issues related to the board. Customers can access product documentation, including installation manuals and technical specifications, through GE’s official website. In the event of a warranty claim, GE will work to provide a prompt resolution, either through repair or replacement of the faulty board, to minimize downtime for the customer’s operations.