Description

VMIVME-1330: Product Overview

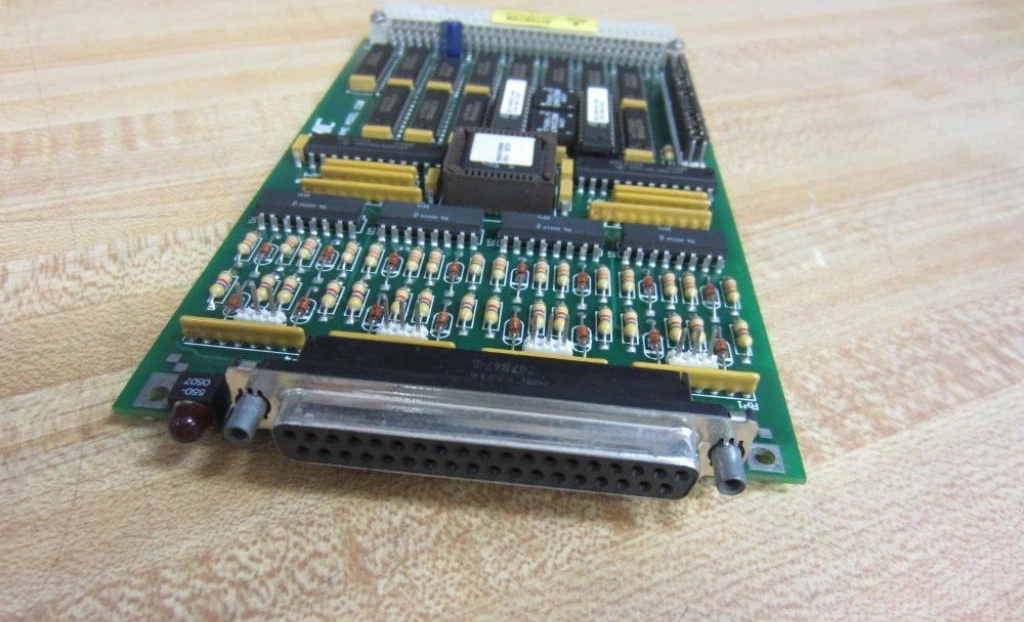

The GE VMIVME-1330 is an optical coupled digital input board designed for VMEbus-based industrial automation systems. As a critical component of the VME ecosystem, it enables reliable digital signal acquisition from field devices (e.g., limit switches, proximity sensors, valve position indicators) and communicates processed digital data to the main controller, supporting real-time control and monitoring in harsh industrial environments.

Role in Automation Systems:

Positioned as a “field signal interface” in VMEbus architectures, the VMIVME-1330 performs two primary functions:

-

Digital Signal Acquisition: Receives digital signals from field devices (e.g., a limit switch indicating a valve is open) and converts them into a format suitable for the VMEbus controller.

-

Signal Conditioning: Filters, amplifies, and isolates raw signals to remove noise and improve integrity, critical for maintaining system stability in industrial environments.

Core Functionality:

-

Optical Coupling: Uses optocouplers to provide galvanic isolation between field devices and the VMEbus, protecting sensitive controller circuits from voltage spikes and electromagnetic interference (EMI).

-

Flexible Signal Configuration: Supports 8-bit or 16-bit data transmission (configurable via hardware jumpers) and accepts voltage source (5–48 V DC) or current sink inputs, accommodating diverse field device requirements.

-

High Isolation: Withstands 1500 V AC continuous voltage, ensuring reliable operation in high-voltage environments (e.g., power generation, petrochemical plants).

-

VMEbus Compatibility: Conforms to VMEbus Rev. C.1, supporting A16/A24 addressing and seamless integration with VMEbus-based controllers (e.g., GE Fanuc 90-30 series).

Platform Benefits (VMEbus Series):

The VMIVME-1330 leverages GE’s VMEbus platform, which is renowned for:

-

Reliability: Industrial-grade components and a rugged design ensure 24/7 operation in harsh environments (e.g., high temperature, vibration).

-

Scalability: Supports expansion with additional I/O boards to accommodate growing system demands (e.g., adding more sensors to a turbine control system).

-

Integration: Seamlessly integrates with VMEbus-based controllers and other I/O modules, reducing setup time and effort.

VMIVME-1330

Technical Specifications

-

Model Number: VMIVME-1330 (Variant: VMIVME-1330-000)

-

Manufacturer: GE (General Electric)

-

Product Type: Optical Coupled Digital Input Board

-

Series: VMEbus

-

Input Channels: 32 (8 ports, 8-bit each)

-

Input Voltage Range: 5–48 V DC (voltage source/current sink)

-

Isolation: 1500 V AC channel-to-channel (galvanic isolation)

-

Signal Types: Dry contact, voltage source, current sink (configurable via jumpers)

-

Bus Standard: VMEbus Rev. C.1 (A16/A24 addressing)

-

Data Transmission: 8-bit/16-bit (configurable via jumpers)

-

Operating Temperature: 0°C to +55°C (32°F to 131°F)

-

Storage Temperature: -40°C to +85°C (-40°F to 185°F)

-

Humidity: 5–95% non-condensing

-

Dimensions: 160 mm × 100 mm × 20 mm (6.3 in × 3.9 in × 0.8 in) (standard VMEbus single-slot)

-

Weight: 0.2 kg (0.44 lbs)

-

Certifications: CE, UL (inferred from GE industrial product standards)

Core Features & Customer Value

1. Reliable Signal Acquisition:

The VMIVME-1330’s optical coupling and high isolation ensure accurate signal transmission from field devices to the VMEbus controller, even in electrically noisy environments. For example, in a power plant, the board can reliably monitor the status of a turbine’s emergency stop button, ensuring safe operation.

2. Flexible Configuration:

Hardware jumpers allow engineers to customize the board’s functionality (e.g., 8-bit/16-bit transmission, voltage source/current sink) without software changes. This flexibility reduces setup time and cost, especially in systems with diverse field devices.

3. Rugged Industrial Design:

The board’s operating temperature range (0°C to +55°C) and compact form factor make it suitable for harsh industrial environments. Its DIN rail mounting option simplifies installation in crowded control cabinets, reducing setup time and effort.

4. Easy Troubleshooting:

LED indicators for power status, input activity, and fault conditions allow operators to quickly identify and resolve issues. This reduces downtime and improves system reliability, which is critical for industrial facilities where unplanned outages can result in significant financial losses.

VMIVME-1330

Typical Applications

The GE VMIVME-1330 is widely used in industrial automation systems for:

-

Power Generation:

-

Monitors digital signals from gas/steam turbines (e.g., valve position switches, emergency stop buttons) and communicates them to the VMEbus controller for real-time control.

-

-

Manufacturing:

-

Used in assembly lines to monitor the status of limit switches, proximity sensors, and other digital devices, enabling precise control of manufacturing processes.

-

-

Petrochemical Industry:

-

Installed in hazardous areas (e.g., refineries, chemical plants) to monitor digital signals from field devices, ensuring safe and reliable operation.

-