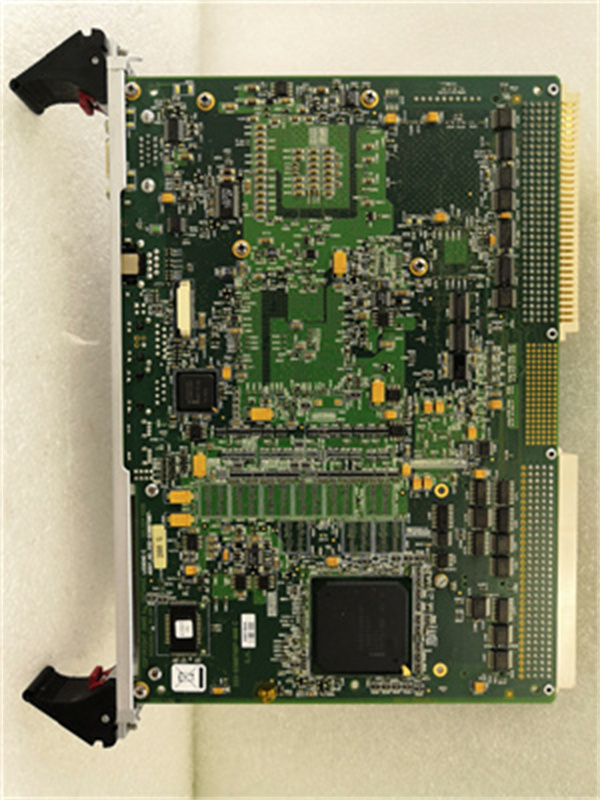

Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | 1756-L81E |

| Manufacturer | Rockwell Automation (Allen-Bradley) |

| Product category | Industrial Programmable Logic Controller (PLC) – ControlLogix 5580 Series |

| Processor Type | 3.5 GHz multi-core Intel® Atom™ processor (dual-core for control tasks) |

| Memory Capacity | 8 GB non-volatile flash memory; 4 GB DDR4 RAM (expandable to 16 GB) |

| I/O Connectivity | Supports up to 5000 I/O points (digital/analog/motion); 1756 ControlLogix chassis compatibility |

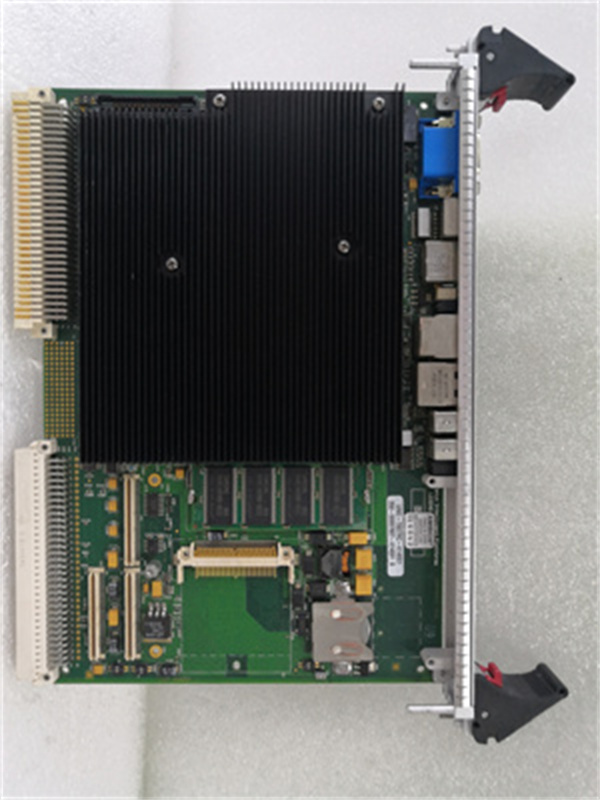

| Communication Ports | 2x 10/100/1000Base-T Ethernet ports (CIP, EtherNet/IP); 1x USB-C (configuration) |

| Real-Time Performance | Task execution cycle: ≥0.1 ms (for 1000 logic rungs); Motion control update rate: 1 ms |

| Operating Temperature Range | 0°C to 60°C (ambient); -40°C to 70°C (extended temperature with optional cooling) |

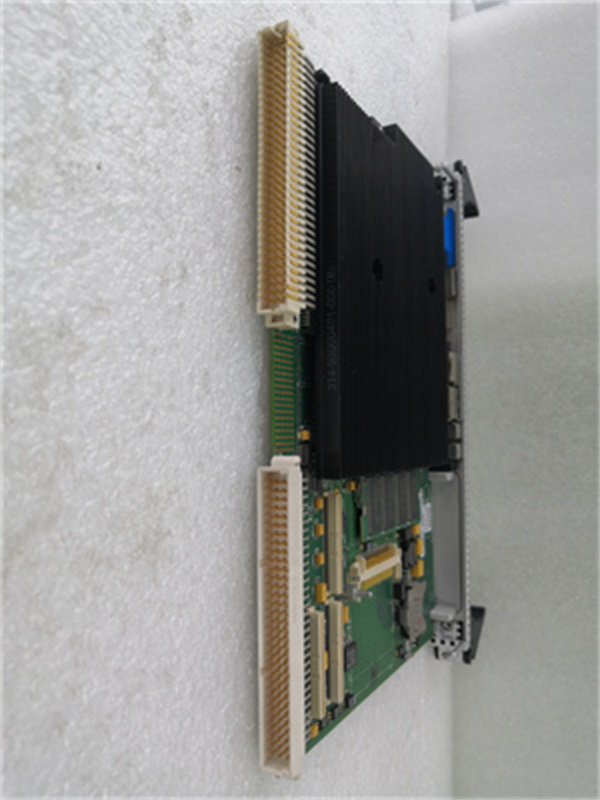

| Physical Dimensions (W×H×D) | 130 mm × 85 mm × 160 mm (fits 1756 ControlLogix chassis slots); Weight: 450 g |

| Installation Method | Slot mounting in Allen-Bradley 1756 ControlLogix chassis (1756-A10/A13/A17) |

| Certifications | CE, UL 508, IEC 61131-2, ATEX Zone 2, IEC 61508 (SIL 2/3 compatible) |

| Power Consumption | 24V DC (from chassis backplane); 1.2 A typical; 2.0 A maximum (peak load) |

| Compatibility | Studio 5000 Logix Designer v32+; 1756 I/O modules (1756-IB16, 1756-OB16); Kinetix 5700 drives |

Product Introduction

The Allen-Bradley 1756-L81E is a flagship industrial PLC in Rockwell Automation’s ControlLogix 5580 Series, engineered to handle complex automation tasks—from discrete manufacturing to process control and motion synchronization. As a next-generation successor to legacy ControlLogix controllers, the Allen-Bradley 1756-L81E integrates a 3.5 GHz multi-core Intel Atom processor, delivering 3x faster logic execution and 2x more memory than previous models, making it ideal for large-scale systems requiring real-time responsiveness.

At its core, the Allen-Bradley 1756-L81E unifies control of digital I/O, analog sensors, and motion devices (e.g., Kinetix 5700 servo drives) under a single platform, eliminating the need for separate controllers. In automation systems, it acts as the “decision-making hub”: it collects data from field devices (via 1756 I/O modules), executes custom logic (programmed in Studio 5000), and sends control commands to actuators—all while ensuring deterministic performance critical for applications like automotive assembly lines or oil refinery processes. The Allen-Bradley 1756-L81E also supports seamless integration with Rockwell’s FactoryTalk ecosystem, enabling end-to-end visibility from machine-level control to enterprise analytics.

Core Advantages and Technical Highlights

Multi-Core Processing for Blazing-Fast Performance: The Allen-Bradley 1756-L81E’s 3.5 GHz dual-core processor dedicates one core to control tasks (logic execution, I/O scanning) and the other to non-critical tasks (data logging, communication), avoiding performance bottlenecks. For example, in a food packaging line with 2000 I/O points, the Allen-Bradley 1756-L81E executes 5000 logic rungs in <0.5 ms—fast enough to synchronize 10 packaging robots with sub-10 ms latency. This speed reduces machine cycle times by up to 20% compared to legacy ControlLogix controllers.

SIL 2/3 Compliance for Safety-Critical Applications: Designed for high-reliability environments, the Allen-Bradley 1756-L81E meets IEC 61508 SIL 2/3 standards, making it suitable for safety-instrumented systems (SIS) like chemical plant emergency shutdowns or power plant turbine protection. It includes built-in fault detection (e.g., memory ECC checks, I/O communication monitoring) that triggers alarms or safe-state actions if anomalies occur. Unlike generic PLCs, the Allen-Bradley 1756-L81E requires no additional safety modules to achieve SIL compliance, simplifying system design and reducing costs.

Seamless Ecosystem Integration: The Allen-Bradley 1756-L81E works natively with Rockwell’s Studio 5000 Logix Designer software, allowing engineers to program logic, configure I/O, and simulate systems in one interface—cutting setup time by 30% compared to mixed-vendor solutions. It also supports EtherNet/IP and CIP protocols, enabling direct communication with FactoryTalk View (HMI software) and FactoryTalk Analytics (cloud-based monitoring). For example, in a pharmaceutical plant, the Allen-Bradley 1756-L81E sends real-time batch data to FactoryTalk Analytics, allowing managers to track production efficiency and compliance with FDA regulations.

Typical Application Scenarios

In automotive manufacturing, the Allen-Bradley 1756-L81E serves as the control core for a body-in-white assembly line, managing 3000 I/O points (including 1756-IB16 digital input modules for robot position sensors and 1756-OB16 output modules for welding guns). Its multi-core processor synchronizes 15 Fanuc robots with 1 ms update rates, ensuring precise weld placement and reducing defect rates by 15%. The Allen-Bradley 1756-L81E also integrates with FactoryTalk ProductionCentre, automatically logging production data (e.g., weld count, cycle time) for quality audits—critical for meeting automotive industry standards (IATF 16949).

In oil and gas processing, the Allen-Bradley 1756-L81E controls a crude oil distillation unit, monitoring 50 analog inputs (temperature, pressure, flow via 1756-IF16 modules) and 200 digital outputs (valves, pumps). Its SIL 3 compliance ensures that if pressure in a distillation column exceeds safe limits, the Allen-Bradley 1756-L81E triggers an emergency shutdown within 100 ms—preventing equipment damage or safety hazards. The controller’s 8 GB flash memory stores 6 months of historical data, enabling engineers to analyze process trends and optimize energy consumption (reducing fuel costs by 8% annually).

Related Model Recommendations

Allen-Bradley 1756-L82E: An upgraded variant of the Allen-Bradley 1756-L81E with a quad-core processor and 16 GB RAM, designed for ultra-large systems (e.g., 10,000+ I/O points) like semiconductor fabs.

Allen-Bradley 1756-IB16: A 16-channel digital input module that pairs with the Allen-Bradley 1756-L81E to collect data from limit switches and proximity sensors in manufacturing lines.

Allen-Bradley 1756-A10: A 10-slot ControlLogix chassis required to mount the Allen-Bradley 1756-L81E and associated I/O modules in compact installations.

Allen-Bradley Kinetix 5700: A servo drive system that integrates with the Allen-Bradley 1756-L81E for motion control applications (e.g., robotic arms, conveyor synchronization).

Allen-Bradley 1756-L81: A legacy predecessor of the Allen-Bradley 1756-L81E with a single-core processor—used for retrofits where full multi-core performance is not required.

Allen-Bradley 1756-IF16: A 16-channel analog input module compatible with the Allen-Bradley 1756-L81E, ideal for monitoring temperature and pressure in process industries.

Allen-Bradley Studio 5000 v35: The latest software version for programming the Allen-Bradley 1756-L81E, featuring enhanced simulation tools and cloud connectivity.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the Allen-Bradley 1756-L81E, ensure the 1756 ControlLogix chassis (e.g., 1756-A10) is powered off and grounded (≥12 AWG wire) to prevent ESD damage. Required tools include a torque screwdriver (0.5 N·m for chassis screws), ESD-safe gloves, and a laptop with Studio 5000 software. Verify the ambient temperature is 0°C–60°C and humidity is 5%–95% (non-condensing) to avoid overheating. Align the Allen-Bradley 1756-L81E with the chassis slot guides and push firmly until it clicks—do not force the module, as this may bend backplane pins.

Maintenance Suggestions: For daily maintenance, check the Allen-Bradley 1756-L81E’s LED indicators (green = normal, red = fault) via the chassis front panel. Use Studio 5000 to review diagnostic logs (e.g., I/O communication errors) weekly. Every 6 months, power down the chassis and inspect the module’s connectors for dust—clean with compressed air (≤30 psi) if needed. If a fault occurs (e.g., red LED), first check the chassis backplane power (24V DC) and I/O module connections. Replace the Allen-Bradley 1756-L81E with a Rockwell-approved spare only if diagnostics confirm a hardware failure; avoid using third-party parts, as they may void the warranty.

Service and Guarantee Commitment

The Allen-Bradley 1756-L81E comes with a 36-month manufacturer’s warranty from Rockwell Automation, covering defects in materials, workmanship, and performance under normal industrial use (per IEC 61131-2 and SIL 3 standards). If the Allen-Bradley 1756-L81E fails within the warranty period, Rockwell provides a “rapid swap” service—delivering a pre-configured replacement within 48 hours for priority customers (e.g., automotive or oil and gas facilities)—minimizing downtime.

Rockwell offers 24/7 global technical support for the Allen-Bradley 1756-L81E, including access to control system specialists via phone/email and remote diagnostics (via secure Ethernet). Customers also receive free access to Studio 5000 software updates for 2 years post-purchase, ensuring compatibility with new I/O modules and features. For enhanced reliability, Rockwell’s ControlLogix Care Program provides annual on-site inspections, firmware updates, and calibration—tailored to your maintenance schedule—reflecting the company’s confidence in the Allen-Bradley 1756-L81E’s durability and commitment to long-term customer success.