Description

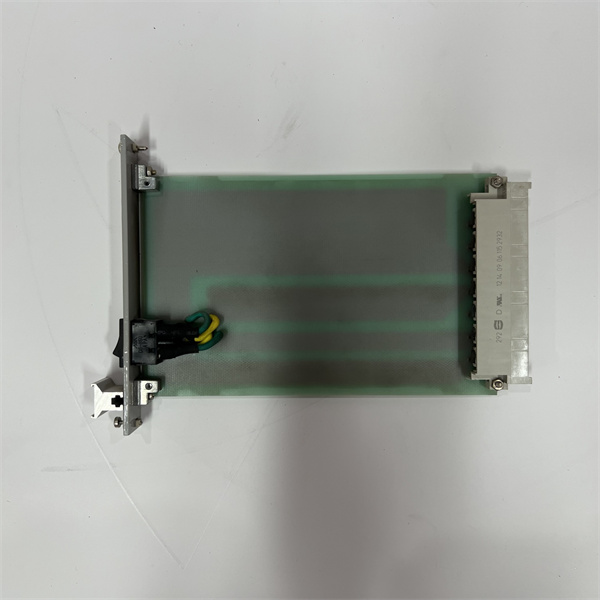

GE WEA13 – 13 2508 – 21001

Product Identification and Nomenclature

The “GE WEA13 – 13 2508 – 21001” is a significant component within GE’s diverse product portfolio. The “WEA13 – 13” likely represents the series or model family, which could be designed for a particular application area, such as industrial automation, data acquisition, or control systems. The “2508 – 21001” is likely a specific part number. This detailed code is used to precisely identify the product’s configuration, including its features, manufacturing batch, and any unique specifications. In a large – scale industrial facility, having such a specific identifier is crucial for inventory management, ensuring that the correct replacement parts are ordered during maintenance, and guaranteeing seamless integration with other components in the system.

Detailed Parameter Table

| Parameter name | Parameter value |

| Product model | WEA13 – 13 2508 – 21001 |

| Manufacturer | GE |

| Product category | Embedded digital module (as inferred from available information, indicating its role in integrating digital functions within a larger system) |

| Signal processing capabilities | Equipped with high – performance general – purpose signal processing capabilities. It can efficiently handle a wide range of signals, making it suitable for applications where real – time signal analysis is required. For example, in a communication system, it can process incoming digital signals, extract relevant information, and perform necessary signal conditioning. |

| Signal acquisition and control | Incorporates automatic gain control technology, which is essential for maintaining consistent signal levels regardless of input signal variations. This is particularly useful in environments with fluctuating signal strengths, such as in wireless sensor networks. It also offers real – time signal display, allowing operators to monitor the status of signals immediately. |

| Digital recording features | Supports multi – channel analog – to – digital (AD) sampling and high – speed storage. This enables it to record large amounts of data in a short time, which is beneficial for applications like data logging in industrial processes or scientific research. For instance, in a power plant, it can record the voltage and current waveforms of electrical systems for later analysis. |

| Special chips and functions | Utilizes a non – magnetic metering System – on – Chip (SoC) chip. This chip can detect rotational motion, which may be used in applications involving motors or rotating machinery. It also has a low – power microcontroller integrated with a high – precision sensor, allowing for accurate measurements and control in energy – sensitive applications. |

| Video – related functions | In applications related to digital video surveillance, it can compress and encode video signals before transmission. This helps in reducing the bandwidth required for video streaming, making it more suitable for network – based surveillance systems. |

| Power supply | Information not provided in the given sources, but likely operates on a standard DC voltage common in industrial or electronic systems, such as 5 VDC, 12 VDC, or 24 VDC, to ensure compatibility with other components. |

| Dimensions | Information not provided in the given sources, but its size would be designed to fit within the form factor of the systems it is intended to be integrated into, whether it’s a compact industrial controller or a larger – scale data acquisition unit. |

| Weight | Information not provided in the given sources, but would be lightweight enough for easy integration and handling in various applications. |

GE WEA13-13 2508-21001

Product Introduction

The GE WEA13 – 13 2508 – 21001 embedded digital module is a versatile and powerful component that plays a crucial role in modern electronic systems. It serves as a building block for enhancing the performance, functionality, and reliability of a wide range of applications.

In today’s fast – paced technological world, there is a growing need for components that can handle complex digital tasks, communicate effectively with other devices, and operate efficiently in various environments. The WEA13 – 13 2508 – 21001 meets these demands by offering a comprehensive set of features. It acts as a central hub for digital signal processing, acquisition, control, and recording within a system. By receiving and processing signals from various sensors, it can make intelligent decisions and transmit control signals to actuators, ensuring the smooth operation of the overall system. Whether it’s used in an industrial automation setup to control machinery, in a data acquisition system to collect and analyze sensor data, or in a digital video surveillance system to manage video streams, this embedded digital module proves to be an invaluable asset.

Core Advantages and Technical Highlights

High – performance signal processing: The high – performance general – purpose signal processing capabilities of the WEA13 – 13 2508 – 21001 allow it to handle complex signal processing tasks with ease. In a telecommunications network, it can quickly demodulate and decode incoming signals, enabling high – speed data transfer. This high – speed processing reduces latency and improves the overall efficiency of the system, leading to better performance in applications where real – time response is critical.

Advanced signal acquisition and control: The automatic gain control technology ensures that the module can adapt to different signal strengths, providing stable and reliable signal input. In a wireless sensor network deployed in a large – scale industrial area, where signal strengths can vary due to distance and interference, the WEA13 – 13 2508 – 21001 can adjust the gain of the received signals, ensuring accurate data collection. The real – time signal display feature also gives operators instant feedback on the status of signals, facilitating quick troubleshooting and system optimization.

Efficient digital recording: With multi – channel AD sampling and high – speed storage, the module can record large volumes of data in real – time. In a power grid monitoring system, it can continuously record the electrical parameters of multiple power lines, which can be used for fault detection, load analysis, and energy management. The ability to store data at high speeds ensures that no valuable information is lost, even during periods of high – frequency signal changes.

Specialized chip functionality: The non – magnetic metering SoC chip and the integrated low – power microcontroller with a high – precision sensor offer unique capabilities. In a smart home system, the rotational motion detection feature can be used to monitor the operation of ceiling fans or window blinds. The low – power consumption of the microcontroller makes it suitable for battery – powered devices, extending the battery life and reducing the need for frequent battery replacements.

Video processing capabilities: In digital video surveillance applications, the video signal compression and encoding function of the WEA13 – 13 2508 – 21001 are highly beneficial. By reducing the size of the video data before transmission, it can save bandwidth and storage space. In a large – scale surveillance network covering a shopping mall or a factory, this feature enables more efficient video streaming and storage, allowing for better monitoring and security management.

Typical Application Scenarios

Industrial automation: In industrial settings, the WEA13 – 13 2508 – 21001 can be used to control and monitor a variety of equipment. It can interface with sensors and actuators to manage the operation of production lines. For example, in a food and beverage factory, it can control the filling and capping machines, ensuring accurate filling levels and proper capping. It can also monitor the temperature, pressure, and flow rate of various processes, adjusting the control parameters in real – time to optimize production efficiency and product quality.

Data acquisition systems: In scientific research or industrial monitoring applications, the module can be used to collect data from multiple sensors. In a environmental monitoring project, it can acquire data from sensors measuring temperature, humidity, air quality, and noise levels. The multi – channel AD sampling and high – speed storage capabilities enable it to record large amounts of data over long periods, which can be analyzed later to identify trends and patterns.

Digital video surveillance: As mentioned earlier, in security systems, the WEA13 – 13 2508 – 21001 can play a key role in video processing. It can be integrated into cameras or video recorders to compress and encode video signals. In a city surveillance network, it can help in transmitting video feeds from multiple cameras to a central monitoring station more efficiently, enabling better surveillance and crime prevention.

Smart home systems: In the context of smart homes, the module can be used to control and monitor various devices. It can communicate with smart sensors, such as motion sensors, door sensors, and temperature sensors, and control smart appliances, like lights, thermostats, and door locks. For example, it can detect when a person enters a room and automatically turn on the lights or adjust the temperature according to the pre – set preferences.

GE WEA13-13 2508-21001

Related Model Recommendations

GE I/O expansion modules: To enhance the input/output capabilities of the WEA13 – 13 2508 – 21001, GE offers a range of I/O expansion modules. These modules can add more digital and analog input/output channels, allowing the embedded digital module to interface with a larger number of sensors and actuators. In an industrial control system where there are numerous sensors and actuators, such as in a large – scale manufacturing plant, these I/O expansion modules can be used to expand the system’s capabilities without having to replace the main module.

GE communication modules: For improved communication, GE provides communication modules that can be paired with the WEA13 – 13 2508 – 21001. These modules support different communication protocols, such as Ethernet, Wi – Fi, and Bluetooth. In a smart home or an industrial IoT (Internet of Things) setup, the Ethernet or Wi – Fi communication modules can enable the module to connect to a local network or the internet, allowing for remote monitoring and control. The Bluetooth module can be used for short – range communication with nearby devices, such as mobile phones or tablets, for convenient configuration and control.

GE power management modules: A stable power supply is essential for the proper operation of the WEA13 – 13 2508 – 21001. GE’s power management modules can provide the necessary power regulation and protection. These modules can ensure that the embedded digital module receives a clean and stable power supply, protecting it from voltage fluctuations, over – voltage, and under – voltage conditions. In areas with unreliable power grids or in applications where power stability is crucial, such as in medical equipment or aerospace systems, these power management modules can significantly improve the reliability of the system.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the WEA13 – 13 2508 – 21001, turn off the power to the system it will be integrated into. Inspect the installation location, such as a circuit board or an industrial enclosure, for any signs of damage or dirt. Clean the area if necessary. Ensure that the power supply available at the installation site is compatible with the module’s power requirements (once the specific power supply details are known). Use anti – static precautions, like wearing an anti – static wrist strap, when handling the module to prevent electrostatic discharge from damaging its sensitive components. Review the installation manual, which should provide details on the correct mounting method, connection points for power and communication lines, and any specific orientation requirements.

Commissioning steps: Mount the WEA13 – 13 2508 – 21001 in the designated location according to the installation manual, using appropriate mounting hardware to secure it firmly. Connect the power cable, making sure the polarity is correct. Connect the communication cables, depending on the communication protocols and devices it will interact with. Power on the system and check for any error indicators or abnormal behavior. Use the relevant software or programming tools to configure the module. This may involve setting up communication parameters, such as IP addresses for network – based communication, and initializing the module’s functions according to the application requirements. Test the module by sending test signals and checking the output responses. For example, if it’s connected to a sensor, send a known input signal and verify that the module processes and outputs the correct result.

Maintenance suggestions: Regularly perform visual inspections of the WEA13 – 13 2508 – 21001. Check for any loose connections, signs of overheating (such as discolored components), or physical damage. Clean the module periodically, especially in dusty environments, using compressed air to remove dust that could affect its performance. Monitor the system logs related to the module. Look for any communication errors, processing delays, or abnormal power consumption. If a problem is detected, first check the cable connections to ensure they are secure. If the issue persists, use the diagnostic tools provided by GE or the relevant software to perform detailed self – diagnostic tests on the module. In case of a component failure, replace the faulty component with a genuine GE replacement part, following the instructions in the user manual to avoid damaging other parts of the module. Also, keep the software or firmware of the module up – to – date to ensure optimal performance and compatibility with the latest technologies.

Service and Guarantee Commitment

GE provides a comprehensive service and guarantee for the WEA13 – 13 2508 – 21001. The product comes with a standard warranty that covers manufacturing defects under normal operating conditions. Their global technical support team is available to assist customers. In case of any issues, they can perform remote diagnostics and troubleshooting. If the problem cannot be resolved remotely, GE can dispatch on – site technicians, depending on the customer’s location and the severity of the issue.

Customers have access to a wealth of online resources, including detailed user manuals, technical specifications, and software programming tools. Training programs are also available, either online or in – person, to help users understand the installation, programming, and maintenance of the WEA13 – 13 2508 – 21001. These training sessions are designed to enhance the user’s skills and knowledge, enabling them to make the most of the module’s capabilities. Extended warranty options may be available, which can provide additional coverage and services such as preventive maintenance checks. This commitment to support ensures that customers can rely on the WEA13 – 13 2508 – 21001 for reliable and efficient operation in their applications.