Description

Detailed Parameter Table

| Parameter name | Parameter value |

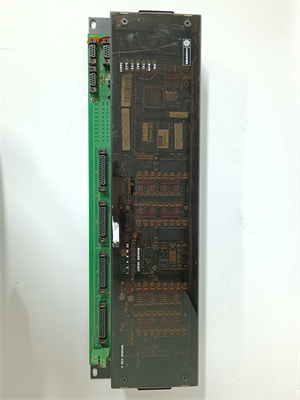

| Product model | WESDAC D20A/0511-0101 |

| Manufacturer | GE (General Electric) |

| Product category | Analog Input Module |

| Series compatibility | GE WESDAC D20 control system |

| Input type | Analog |

| Input range | User-configurable |

| Resolution | 16-bit |

| Isolation | 1500 VRMS |

| Input channels | 8 |

| Communication interface | RS-485 |

| Power supply | 24 VDC |

| Operating temperature | -40°C to +75°C |

| Dimensions | [Specify if available, e.g., length x width x height in mm] |

| Weight | [Specify if available in kg or g] |

GE WESDAC D20A/0511-0101

Product Introduction

The GE WESDAC D20A/0511-0101 is a highly versatile analog input module engineered as an integral part of the GE WESDAC D20 control system. This module plays a crucial role in industrial automation by providing accurate and reliable analog input measurements for monitoring and control applications.

Designed to meet the demands of diverse industrial processes, the WESDAC D20A/0511-0101 converts analog signals from various sensors (such as temperature, pressure, and flow sensors) into digital data that can be processed by the control system. Its user-configurable input range allows for seamless integration with a wide range of sensor types, making it adaptable to different industrial scenarios. With 8 input channels and a 16-bit resolution, this module ensures high-precision data acquisition, enabling precise control and optimization of industrial processes.

Core Advantages and Technical Highlights

High-precision analog measurement: The 16-bit resolution of the GE WESDAC D20A/0511-0101 enables extremely accurate conversion of analog signals. In chemical processing plants, for example, it can precisely measure minute changes in pressure and temperature, ensuring optimal reaction conditions and product quality. This high precision reduces errors in control loops, leading to more stable and efficient operation of industrial systems.

User-configurable input range: The ability to configure the input range according to sensor requirements makes the WESDAC D20A/0511-0101 highly flexible. In a manufacturing facility with a mix of different sensor technologies, this module can be easily adjusted to interface with sensors that have different voltage or current output ranges. This eliminates the need for additional signal conditioning hardware, reducing system complexity and cost.

Robust isolation and reliability: With 1500 VRMS isolation, the module protects the control system from electrical interference and voltage spikes. In industrial environments where electrical noise is prevalent, such as in power generation plants or metalworking factories, this isolation feature ensures the integrity of the analog input signals. The module’s wide operating temperature range from -40°C to +75°C makes it suitable for deployment in harsh environments, whether it’s in a cold storage facility or a hot industrial furnace area.

Efficient communication interface: The RS-485 communication interface of the GE WESDAC D20A/0511-0101 allows for reliable and fast data transfer to the control system. This interface is widely used in industrial settings for its ability to support multiple devices on a single bus, enabling easy expansion of the analog input system. In a large-scale oil refinery, for instance, multiple WESDAC D20A/0511-0101 modules can be daisy-chained together using the RS-485 interface to connect hundreds of sensors to the central control system.

Typical Application Scenarios

Industrial process control: In a pharmaceutical manufacturing plant, the GE WESDAC D20A/0511-0101 monitors the temperature, pressure, and flow rate of chemical reactions during drug synthesis. It provides real-time data to the control system, which adjusts the process parameters to ensure consistent product quality. The module’s high precision is critical in this application, as even small variations in process conditions can affect the efficacy of the drugs being produced.

Power generation and distribution: In a power plant, the module measures the temperature of turbines, the pressure of steam, and the flow rate of cooling water. This data is used to optimize the power generation process, ensuring efficient operation and preventing equipment failures. In electrical substations, it monitors the voltage and current levels of power lines, providing essential data for grid management and protection systems.

Environmental monitoring: In a wastewater treatment plant, the WESDAC D20A/0511-0101 measures parameters such as pH, dissolved oxygen, and turbidity. This data helps operators manage the treatment process to meet environmental regulations. In air quality monitoring stations, it can measure the concentration of pollutants in the air, providing valuable data for environmental protection agencies.

GE WESDAC D20A/0511-0101

Related Model Recommendations

GE WESDAC D20D/0511-0101: A digital input/output module that can be used in conjunction with the WESDAC D20A/0511-0101 to create a comprehensive I/O system for industrial control. It is useful for applications that require both analog and digital signal handling, such as in a bottling plant where analog sensors monitor liquid levels and digital sensors detect bottle presence.

GE WESDAC D20PS: A specialized power supply unit for the WESDAC D20 system. It ensures stable power delivery to the WESDAC D20A/0511-0101 and other modules in the system, which is crucial for reliable operation in industrial environments. In a mining operation, where power fluctuations are common, this power supply unit helps maintain the integrity of the analog input measurements.

GE WESDAC D20ME: A controller module that can process the analog data received from the WESDAC D20A/0511-0101. It is capable of executing control logic based on the input data, making it suitable for applications where real-time control decisions are required. In a food processing plant, the WESDAC D20ME can adjust conveyor speeds or ingredient dosages based on the analog data from sensors monitoring product quality.

GE WESDAC D20HMI: A human-machine interface module that can display the analog data collected by the WESDAC D20A/0511-0101 in a user-friendly format. Operators can use this interface to monitor process variables and make adjustments if necessary. In a water treatment facility, operators can view real-time water quality data on the HMI and take corrective actions as needed.

GE WESDAC D20ALG: An analog signal conditioning module that can be used to further enhance the performance of the WESDAC D20A/0511-0101. It can filter out noise and adjust the signal levels to ensure optimal input to the analog input module. In a noisy industrial environment, such as a metal stamping factory, this signal conditioning module can improve the accuracy of the analog measurements.

GE WESDAC D20COMM: A communication expansion module that can add additional communication capabilities to the system. It can be used to connect the WESDAC D20A/0511-0101 to other networks or devices, enabling remote monitoring and control. In a distributed industrial system spread across multiple locations, this module allows for centralized management of the analog input data.

GE WESDAC D20RACK: A rack system that provides a physical structure for mounting the WESDAC D20A/0511-0101 and other modules. It helps organize the system components and ensures proper ventilation and electrical connections. In a large industrial control room, the rack system keeps the modules neatly arranged and 便于维护.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the GE WESDAC D20A/0511-0101, ensure that the WESDAC D20 control system rack is properly mounted and grounded. Verify that the power supply is providing a stable 24 VDC. Use a multimeter to check for any voltage fluctuations or electrical noise in the power supply. Gather the necessary tools, such as a screwdriver for securing the module in the rack and wire strippers for connecting the sensor cables. Label all the wires and connectors to avoid confusion during installation. Make sure the installation area is clean and free from dust and moisture, as these can affect the performance of the module.

Maintenance suggestions: Conduct regular visual inspections of the WESDAC D20A/0511-0101 to check for any loose connections, signs of overheating (such as discolored components), or physical damage. Clean the module periodically using compressed air to remove dust and debris, especially from the ventilation slots. Check the communication interface regularly to ensure that data is being transmitted correctly. Use diagnostic tools provided by GE to test the functionality of the module, such as injecting known analog signals and verifying the digital output. Back up the configuration data of the module periodically to prevent data loss in case of a module failure. Replace the module if it shows signs of consistent malfunction or if it no longer meets the accuracy requirements of the application.

Service and Guarantee Commitment

GE offers a [specify warranty period, e.g., 12-month] warranty for the GE WESDAC D20A/0511-0101, covering manufacturing defects and component failures under normal operating conditions. The company’s global technical support team is available 24/7 via phone, email, and online chat to assist customers with any technical issues. On-site service can be arranged in major industrial regions for more complex problems.

Customers can access a wealth of resources, including user manuals, technical documentation, and firmware updates, through GE’s industrial support portal. Training courses are available to help system integrators and maintenance personnel understand the installation, configuration, and maintenance of the WESDAC D20A/0511-0101. For critical applications, GE may offer extended warranty plans with additional benefits such as priority support and preventive maintenance services. This comprehensive service and support commitment ensure that the GE WESDAC D20A/0511-0101 delivers reliable performance throughout its operational lifespan.