Description

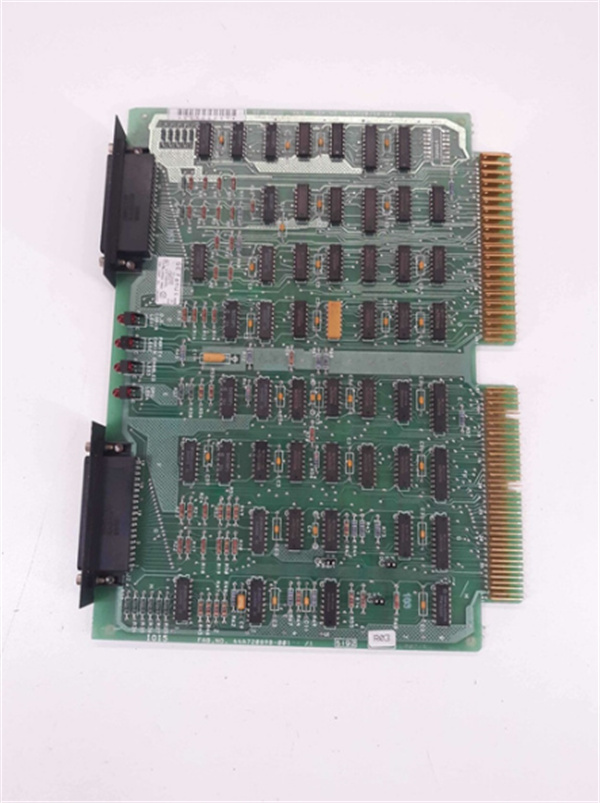

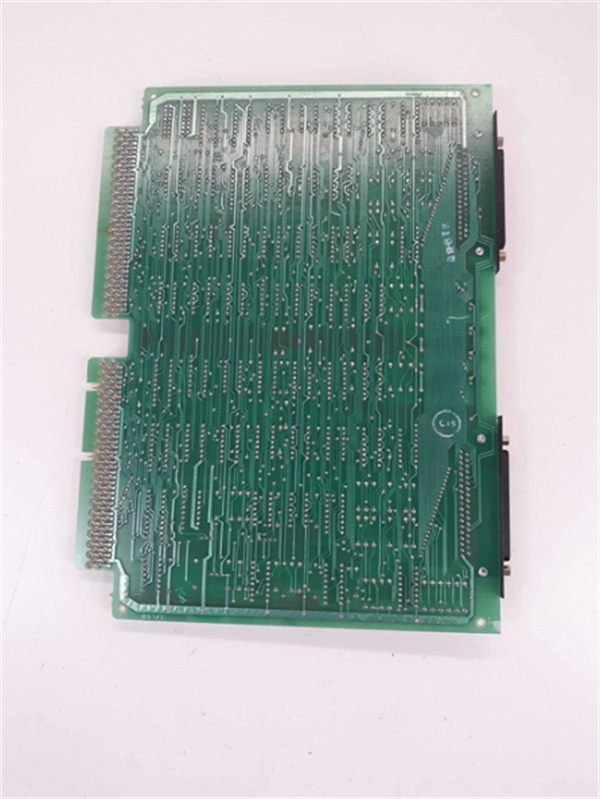

The GE IC600CB524M is an arithmetic control module designed by GE Fanuc for its Series Six product line. It plays a vital role in industrial automation systems, responsible for performing arithmetic and logical operations for Series Six CPUs.

This module features a bit – slice architecture, enabling high – speed processing and supporting all instruction sets of the GE Series Six CPU, including the expanded set for enhanced functionality and backward compatibility. It has two LED indicators, “run” and “check”, which are used to indicate the CPU status and simplify troubleshooting. The GE IC600CB524M can be used with different CPU models, such as model 60, model 600, and model 6000 CPUs, helping to reduce spare parts inventory.

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC600CB524M |

| Manufacturer | GE Fanuc |

| Product Type | Arithmetic Control Module |

| Dimensions (Shipping) | 16.00 in x 14.00 in x 3.00 in (approx. 40.64 cm x 35.56 cm x 7.62 cm) |

| Weight | 2.00 lbs (approx. 0.91 kg) |

| Voltage Rating | Not specified |

| Communication Protocol | Not applicable |

| Operating Temperature Range | Not specified |

| Storage Temperature Range | Not specified |

IC600CB527M

Reliable and stable

The GE IC600CB524M is designed with high – quality components and advanced manufacturing processes, ensuring reliable operation in industrial environments. Its bit – slice architecture and dedicated design for Series Six CPUs provide stable performance for arithmetic and logical operations.

Easy to maintain

With its two LED indicators, the “run” and “check” lights, it is easy to monitor the operating status of the module. This allows for quick identification of any potential problems, simplifying the troubleshooting and maintenance process.

Flexible compatibility

This module is compatible with multiple CPU models in the GE Series Six product line, including model 60, model 600, and model 6000 CPUs. This wide range of compatibility offers users flexibility in system configuration and expansion, reducing the need for frequent hardware replacements.

The GE IC600CB524M is mainly used in industrial automation systems that utilize GE Fanuc’s Series Six CPUs. It is suitable for various industrial scenarios such as manufacturing plants, power plants, and chemical plants, where reliable arithmetic and logical operations are required for process control and monitoring.

For example, in a manufacturing plant, the GE IC600CB524M can be used to perform complex calculations for production line control, such as calculating the speed and position of conveyor belts, or monitoring the quality control data of products. In a power plant, it can be used to process data from various sensors and perform arithmetic operations to ensure the stable operation of the power generation process.

IC600CB527M

Related Products

- IC600CB524A – IC600CB524Z: These are different revisions of the IC600CB524 series, which may have some differences in functionality or design compared to the IC600CB524M6.

- GE Series Six CPUs: Such as model 60, model 600, and model 6000 CPUs, are the main application platforms of the GE IC600CB524M, and they work together to complete the arithmetic and logical operations in the industrial automation system.

Pre – installation preparation

Before installing the GE IC600CB524M, make sure to carefully read the installation manual. Check the compatibility of the module with the existing system, especially ensure that it is suitable for the specific GE Fanuc Series Six CPU model used. Prepare the necessary tools and ensure that the installation environment is clean and free of interference.

Maintenance recommendations

Regularly check the status of the two LED indicators on the GE IC600CB524M to monitor the operating condition of the module. If any abnormality is found, refer to the troubleshooting guide in the manual for inspection and repair. Keep the module clean and free of dust, and periodically check the connection of the ribbon cable to ensure a reliable connection.

GE is committed to providing high – quality products and services. The GE IC600CB524M comes with a certain – period quality assurance. If there is any quality problem with the product during the warranty period, GE will provide free repair or replacement services. In addition, GE also provides comprehensive technical support to help users solve various problems encountered in the process of using the product, ensuring the stable operation of the industrial automation system.