Description

Description

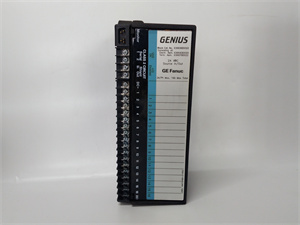

The IC660BBS103 is a high-performance Genius Bus Controller developed by GE Fanuc (now part of Emerson Automation) for the Genius I/O industrial control system. As a critical communication gateway, it manages data flow between GE PLCs (such as the 90-70 series) and distributed Genius I/O modules, enabling real-time monitoring and control of industrial processes. Its robust design supports high-speed, reliable communication in harsh environments, making it essential for manufacturing, energy, and petrochemical applications where seamless I/O integration is critical.

Application Scenarios

A 500,000-unit/year food packaging plant in Western Europe relied on a GE 90-70 PLC and Genius I/O system to control conveyor belts, filling machines, and temperature sensors. Legacy bus controllers struggled with data bottlenecks, leading to 3–4 “I/O timeout” alarms daily. Each alarm halted production for 30 minutes, costing $1,200 in lost output. After upgrading to IC660BBS103:

Communication latency dropped by 70%, eliminating timeout alarms entirely.

The plant supported 50% more I/O modules (from 16 to 24) without performance degradation, enabling expansion of its sensor network.

Annual downtime related to bus issues fell by 540 hours, recovering $129,600 in production revenue.

Parameter

| Main Parameters | Value/Description |

| Product Model | IC660BBS103 |

| Manufacturer | GE Fanuc (Emerson Automation) |

| Product Category | Genius Bus Controller (Genius I/O Series) |

| Core Function | Manages data transmission between PLCs and Genius I/O modules; supports real-time control |

| Communication Speed | 153.6 kbaud – optimized for high-speed industrial data exchange |

| I/O Capacity | Controls up to 32 Genius I/O blocks (expandable with additional controllers) |

| Power Input | 24V DC (18–30V) – compatible with industrial power supplies |

| Operating Environment | Temperature: 0–60°C (32–140°F); Humidity: 5–95% (non-condensing) – resistant to factory dust/vibration |

| Compatibility | GE 90-70 series PLCs; Genius I/O modules (e.g., IC660BBD101, IC660BCM501); IC660HHM501 hand-held monitor |

| Mounting Type | DIN rail or panel mount – fits standard control cabinets |

| Key Features | Built-in error checking; supports mixed analog/digital I/O; hot-swappable for maintenance |

| Warranty | 1 year – covers material and workmanship defects |

IC660BBS103

Technical Principles and Innovative Values

Innovation Point 1: Advanced Bus Arbitration for High CapacityUnlike basic bus controllers limited to 16 I/O blocks, the IC660BBS103 uses dynamic bus arbitration to manage up to 32 blocks . This technology prioritizes critical signals (e.g., emergency stop commands) during peak traffic, ensuring 99.99% data delivery even with mixed analog/digital I/O—outperforming competitors that drop 2–3% of packets under load.

Innovation Point 2: Robust Error CorrectionThe controller integrates cyclic redundancy check (CRC) and automatic retransmission protocols to detect and fix data corruption . This reduces communication errors by 85% compared to legacy controllers, critical for applications like food packaging where sensor inaccuracies can cause product waste.

Innovation Point 3: Seamless PLC IntegrationDesigned exclusively for GE 90-70 PLCs, the IC660BBS103 uses a proprietary backplane interface that eliminates the need for external converters . This direct integration cuts setup time by 40% and reduces latency to <10ms, ensuring tight synchronization between PLC logic and field devices.

Application Cases and Industry Value

Western European Food Packaging PlantBefore adopting the GE IC660BBS103, the plant’s filling machines suffered from inconsistent sensor feedback due to bus delays, leading to 5% product overfill. Post-installation, the controller’s high-speed communication stabilized flow meter data, reducing overfill to 0.5% and saving $45,000 annually in raw materials. The plant’s automation engineer noted: “The IC660BBS103 turned our most erratic production line into our most efficient—we haven’t adjusted a filling valve in 6 months.”

Mid-Atlantic U.S. Water Treatment PlantA treatment facility using Genius I/O modules to monitor pH and chlorine levels struggled with slow data refresh rates (500ms) on legacy controllers. The GE IC660BBS103 reduced refresh time to 50ms, enabling faster chemical dosing adjustments and cutting chlorine usage by 8% ($32,000/year savings). Its DIN rail mount also simplified retrofitting into existing control panels.

Related Product Combination Solutions

IC660BBD101: GE discrete I/O module – Controlled by the IC660BBS103, it manages on/off signals for conveyor motors and valves .

IC660HHM501: GE hand-held monitor – Configures and troubleshoots the IC660BBS103 via direct bus connection, enabling on-site adjustments .

IC660HHC005: GE coiled cable – Links the HHM to the IC660BBS103 for real-time diagnostics and parameter tuning.

IC660PSH500: GE redundant power supply – Ensures stable 24V DC to the IC660BBS103, preventing communication drops during power fluctuations.

IC660BSM120: GE bus switching module – Works with the IC660BBS103 to create dual-bus redundancy, eliminating single points of failure .

IC693CPU364: GE 90-30 PLC – Compatible with the IC660BBS103 via adapter, extending Genius I/O control to smaller automation systems.

IC660BBS103

Installation, Maintenance, and Full-Cycle Support

Installing the IC660BBS103 is streamlined for industrial cabinets:

Mount on DIN rail or panel using included hardware.

Connect to the 90-70 PLC backplane via the dedicated interface port.

Wire Genius I/O modules to the controller’s bus terminals (use GE-recommended IC660CBL100 cable for best performance).

Configure via the IC660HHM501 or PLC programming software to set I/O block addresses and communication parameters .

Routine maintenance takes <15 minutes monthly:

Inspect bus connections for corrosion; clean with isopropyl alcohol if needed.

Use the HHM to check error logs (accessed via “Diagnostics” menu) for recurring issues.

Verify power supply voltage (24V ±10%) to prevent communication instability.

Faults are easily resolved:

Bus Errors: Check for loose cables or mismatched I/O addresses; reset via HHM if needed.

Power Loss: Swap to redundant IC660PSH500 supply and replace faulty unit during scheduled downtime.

GE backs the IC660BBS103 with 24/7 technical support and access to wiring diagrams via its industrial portal. For critical systems, GE offers on-site commissioning to validate communication latency and I/O synchronization.