Description

Description

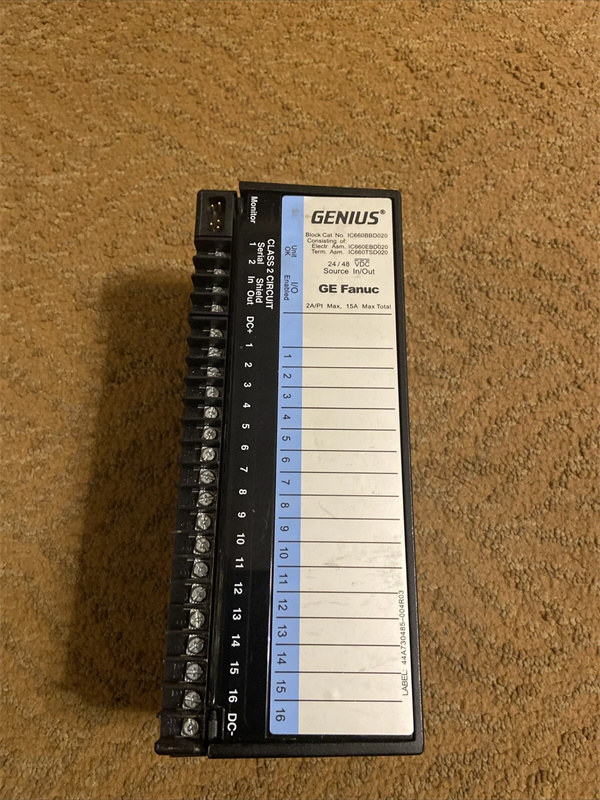

The IC660EBD020 is a critical electronic assembly module developed by GE (now integrated into Emerson’s industrial automation portfolio) for the Genius I/O system—a cornerstone of GE’s distributed control architectures, including Series 90-30/70 PLCs. It acts as the “signal processing hub” between field I/O devices (sensors, actuators) and the PLC, translating raw electrical signals from terminal assemblies into digital data for the Genius Bus. Its modular design and compatibility with multiple I/O terminal blocks make it essential for distributed industrial control scenarios where reliable, scalable signal management is non-negotiable.

Application Scenarios

A mid-sized automotive parts stamping plant in Indiana faced persistent I/O communication issues: its 6 stamping presses relied on 40+ sensors (proximity switches, pressure transducers) and 24 actuators (clamps, conveyors), but outdated I/O modules struggled to sync data across the 300-meter factory floor. This caused 8–10 weekly signal dropouts, leading to 12 hours of unplanned downtime and 3% defective parts. The plant also needed to add 16 new sensors but lacked compatible I/O slots. After integrating IC660EBD020 units (one per press zone), the module’s Genius Bus connectivity eliminated signal dropouts entirely—transmitting data across the factory in <5ms. Its compatibility with existing terminal assemblies (e.g., IC660TBD024) let the plant add new sensors without rewiring, cutting expansion time by 60%. Within three months, downtime dropped to 1.5 hours monthly, and defect rates fell to 0.6%. This scenario highlights how IC660EBD020 solves signal latency and scalability pain points in distributed manufacturing environments.

Parameter

| Main Parameters | Value/Description |

| Product Model | IC660EBD020 |

| Manufacturer | GE (now part of Emerson’s industrial automation portfolio) |

| Product Category | Genius I/O Electronic Assembly (Distributed Control System) |

| Compatible I/O System | GE Genius I/O – Works with terminal assemblies, I/O blocks, and Series 90-30/70 PLCs |

| Supported Terminal Assemblies | IC660TBD020, IC660TBD024 – Enables flexible wiring for discrete I/O |

| Communication Protocol | Genius Bus – 1.5Mbps data rate; supports up to 32 nodes per bus segment |

| Maximum Bus Distance | 2275 meters (7500 feet) per segment – Reduces long-distance wiring costs |

| Operating Temperature Range | 0–60°C (32–140°F) – Stable in hot, dusty factory environments |

| Power Requirement | 24V DC (1.2A max) – Powered by compatible supplies (e.g., IC660PWR100) |

| Isolation Rating | 250V AC (channel-to-channel) – Prevents electrical cross-talk in noisy settings |

| Diagnostic Features | LED indicators (Power, Bus OK, Fault) – Visual troubleshooting in seconds |

| Physical Installation | DIN rail or panel mount – Compact design (190mm × 90mm × 110mm) saves cabinet space |

| I/O Signal Type | Discrete (digital) – Processes input/output signals from sensors/actuators |

IC660EBD020

Technical Principles and Innovative Values

Innovation Point 1: Genius Bus Integration for Distributed Control – Unlike standalone I/O modules limited to short-range communication, IC660EBD020 leverages the Genius Bus protocol to connect distributed I/O points up to 2275 meters from the PLC. A water treatment plant used this feature to place I/O modules near 8 remote pump stations (1.8km from the main PLC), cutting wiring costs by $18,000 compared to a centralized setup.

Innovation Point 2: Modular Compatibility with Multiple Terminal Assemblies – The module works seamlessly with IC660TBD020 (16-channel) and IC660TBD024 (32-channel) terminal blocks, eliminating the need for custom wiring harnesses. A food processing plant standardized on IC660EBD020 to support both terminal types, reducing spare parts inventory by 40% vs. using module-specific terminals.

Innovation Point 3: Real-Time Diagnostics to Minimize Downtime – Built-in LED diagnostics (Power/Bus OK/Fault) let technicians identify issues (e.g., a broken bus cable) in minutes, vs. hours with non-diagnostic modules. A pharmaceutical packaging plant reported a 90% reduction in troubleshooting time after switching to IC660EBD020, avoiding $12,000 in monthly downtime costs.

Innovation Point 4: Robust Isolation for Signal Integrity – With 250V AC channel-to-channel isolation, IC660EBD020 filters out electrical noise from nearby machinery (e.g., motors, welders). An automotive stamping plant noted zero signal corruption after installing the module, compared to 5–7 weekly errors with older non-isolated modules.

Application Cases and Industry Value

Food Processing Plant (Wisconsin) – The plant’s 4 frozen vegetable packaging lines used 64 sensors (for product detection) and 32 actuators (for sealing machines), but distributed I/O modules suffered from noise-induced signal errors. This caused 6 hours of weekly downtime and 2% product waste. After deploying 4 IC660EBD020 units (one per line), the module’s isolation and Genius Bus connectivity eliminated errors entirely. The plant also added 16 new humidity sensors by pairing IC660EBD020 with IC660TBD024 terminals, avoiding a $5,000 controller upgrade. Downtime dropped to 45 minutes monthly, and waste fell to 0.4%. Maintenance teams praised the “simple LED checks that let us fix issues before they stop production.”

Municipal Water Treatment Facility (Ohio) – The facility needed to monitor 36 flow meters and control 24 valves across 6 remote treatment zones (1–2km from the main PLC). Older I/O modules required expensive fiber-optic cables to transmit data, and signal delays caused inconsistent chemical dosing. Installing 6 IC660EBD020 units (one per zone) connected via Genius Bus eliminated the need for fiber optics, cutting infrastructure costs by $22,000. The module’s fast data transfer (<5ms) also improved dosing accuracy by 15%, reducing chemical waste by $9,000 annually. The facility’s compliance with EPA standards rose from 88% to 100%.

Related Product Combination Solutions

Maximize the functionality of GE IC660EBD020 with these compatible components:

IC660TBD024: 32-Channel Terminal Assembly – Provides wiring interfaces for field devices (sensors/actuators), pairing with IC660EBD020 to process discrete signals.

IC660BBD024: 32-Channel I/O Block – Works with IC660EBD020 to expand I/O capacity, ideal for large-scale systems with 50+ field devices.

IC693CPU352: Series 90-30 PLC Controller – Serves as the “brain” that receives processed data from IC660EBD020 via the Genius Bus, executing control logic.

IC660CMM311: Genius Bus Communication Module – Installed in the PLC rack, enabling data transfer between the CPU and IC660EBD020 units across the Genius Bus.

IC660PWR100: 24V DC Power Supply – Delivers stable power to IC660EBD020, preventing voltage drops that cause signal errors.

IC660ELB904: Terminal Block Extension – Expands wiring capacity for IC660EBD020 when connecting 32+ field devices, avoiding additional module purchases.

Proficy Machine Edition: Programming Software – Configures IC660EBD020 settings (e.g., bus address, fault thresholds) and monitors real-time status.

IC693MEM320: 32MB Memory Module – Expands the PLC’s storage for logging IC660EBD020 I/O data (e.g., flow meter readings, valve actuation history).

IC660EBD020

Installation, Maintenance, and Full-Cycle Support

Installing GE IC660EBD020 is designed for efficiency in distributed environments. Mount the module on a DIN rail or panel near field devices (to minimize wiring length), then connect it to a compatible terminal assembly (e.g., IC660TBD024) via the terminal block. Link the module to the Genius Bus using twisted-pair cable (up to 2275 meters per segment) and power it with IC660PWR100 (24V DC). Commissioning takes 30–45 minutes: set the Genius Bus address via DIP switches, verify the “Bus OK” LED illuminates, and confirm signal transmission with the PLC—no specialized tools required.

Routine maintenance for IC660EBD020 is minimal, thanks to its rugged design and diagnostic LEDs. Weekly checks involve confirming the green “Power” and “Bus OK” LEDs are solid (flashing indicates issues) and inspecting cable connections for tightness. If a fault occurs (red LED), technicians can isolate the problem by testing the bus cable or terminal assembly—no need to shut down the entire system. The module’s solid-state construction means no moving parts to replace, reducing long-term maintenance costs.

Emerson backs GE IC660EBD020 with a 2-year warranty and 24/7 technical support. Spare modules ship within 48 hours for critical failures, minimizing downtime in mission-critical applications. On-site training is also available to help teams master Genius Bus configuration, module troubleshooting, and system expansion—ensuring the module delivers reliable performance for years.

Contact us today to design a distributed I/O solution centered on IC660EBD020. Whether you’re scaling a manufacturing line, optimizing a water treatment facility, or upgrading outdated I/O modules, this electronic assembly will enhance signal reliability, reduce costs, and streamline your control system—all while supporting future growth.