Description

Product Overview

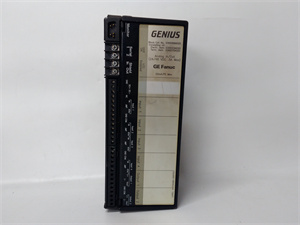

The GE IC660TSA100 is a terminal assembly block that belongs to the Genius I/O series by GE Fanuc. It plays a pivotal role in industrial automation systems, especially when integrating GE Fanuc series 90 – 70 programmable logic controllers (PLCs) with field devices. This module serves as a crucial interface, facilitating the connection of field wiring to I/O modules. With 4 analog inputs and 2 analog outputs, the IC660TSA100 is designed to handle a variety of analog signals. It can be powered by either a single – phase 115V AC utility line or a 24 – 48V DC power supply, providing flexibility in different industrial setups. Its solid – state design ensures high reliability and stable performance, making it an essential component for applications that require accurate data acquisition and signal processing.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC660TSA100 |

| Manufacturer | GE Fanuc |

| Product Type | Genius I/O terminal assembly module |

| Analog Inputs | 4 |

| Analog Outputs | 2 |

| Input Voltage | 115V AC or 24 – 48V DC |

| Operating Temperature Range | 0 °C to 60 °C |

| Dimensions | 8.83″ H x 3.50″ W x 3.94″ D |

| Weight | 1.08 lbs |

| Communication Protocol | Genius protocol |

| Accuracy | ±0.5% at 25 °C |

| Power Supply Range | 10 – 50 VDC (in some applications) |

| Signal Range | 4 – 20 mA (in some applications) |

IC660ELB912G

Main Features and Advantages

The GE IC660TSA100 offers several notable features. Its modular design allows for easy installation and maintenance. This means that in case of any issues, the module can be quickly replaced, reducing downtime in industrial operations. The wide power supply options, being able to operate on either 115V AC or 24 – 48V DC, make it adaptable to different power sources available in various industrial settings.

It comes equipped with built – in diagnostic features. These features can quickly detect any faults or malfunctions in the module or the connected devices. For example, if there is an issue with an analog input signal, the diagnostic system can identify the problem and report it, enabling prompt troubleshooting. Additionally, the module has a port for connecting monitoring devices, which allows for real – time monitoring of its performance.

In terms of accuracy, the IC660TSA100 has an accuracy rating of ±0.5% at 25 °C, ensuring reliable data acquisition. This level of accuracy is crucial for applications where precise measurement of analog signals is required, such as in process control systems.

Application Field

The GE IC660TSA100 finds extensive applications in multiple industries. In the manufacturing industry, it is used to connect sensors and actuators to PLCs. For instance, in an automotive assembly line, it can interface with sensors that detect the position of parts and actuators that control robotic arms. By accurately handling analog signals from these devices, it helps in ensuring the smooth and precise operation of the assembly process.

In the energy sector, particularly in power plants, the IC660TSA100 is utilized to monitor and control various parameters. It can be connected to sensors that measure temperature, pressure, and flow of steam or other fluids. This data is then used to optimize the operation of turbines and generators, improving the overall efficiency of power generation.

In the process industry, such as in chemical plants or food processing facilities, the module plays a vital role. In a chemical plant, it can handle analog signals from sensors that monitor the concentration of chemicals in a reaction vessel. Based on this data, the PLC can adjust the flow of reactants, ensuring the chemical reactions occur under optimal conditions. Similarly, in a food processing plant, it can be used to control the speed of conveyor belts or the temperature in cooking or cooling processes.

IC660ELB912G

Related Products

- IC660EBA100: Often used in combination with the IC660TSA100, it further processes and distributes signals within the I/O system. It may have additional functionality for signal conditioning or amplification, enhancing the overall performance of the I/O setup.

- IC660ELD100A: Belongs to the same Genius I/O series. It likely focuses on digital signal processing, which can work in tandem with the IC660TSA100‘s analog capabilities. Together, they can handle both analog and digital signals in more complex industrial control systems.

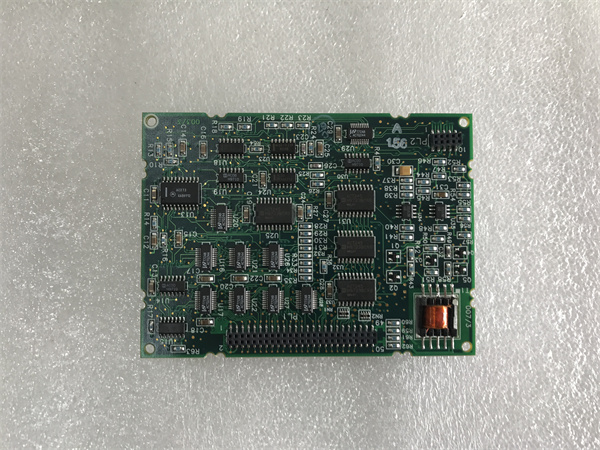

- IC660ELB912G: A microgeni daughterboard that is part of the Genius I/O network. It is involved in tasks like initialization and fault management. It can cooperate with the IC660TSA100 to improve the overall stability and management of the system, especially in terms of network – related operations.

- IC660TSD100: Another terminal assembly in the Genius series. It provides 8 – circuit combination input and output, which is useful for applications that require a higher number of input and output channels compared to the IC660TSA100. In some cases, they may be used in different sections of the same industrial process, with the IC660TSD100 handling more complex I/O requirements.

- IC660BBA100: Connects to the IC660TSA100 in certain systems. It may be responsible for tasks such as signal buffering or isolation, helping to optimize the performance of the overall I/O system and ensuring the integrity of the signals being transmitted.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IC660TSA100, ensure that the power supply to the system is turned off. Thoroughly inspect the module for any visible signs of damage during transit. Familiarize yourself with the installation manual, which provides detailed instructions on wiring and connection procedures. Check the compatibility of the IC660TSA100 with other components in the system, especially the power supply and the PLC it will be connected to. Make sure the working environment meets the temperature and humidity requirements specified for the module.

Maintenance recommendations: Regularly monitor the IC660TSA100 for any abnormal behavior. Check the indicator lights (if available) to ensure normal operation. Periodically clean the module to remove dust and debris, as these can affect its performance over time. Inspect the connections of all wires and cables to ensure they are secure. If any issues are detected, such as incorrect readings from analog inputs or problems with the diagnostic features, refer to the troubleshooting section of the product manual. Consider performing regular calibration of the analog inputs to maintain the module’s accuracy.

Product Guarantee

GE Fanuc stands firmly behind the quality of the IC660TSA100. The product comes with a comprehensive quality assurance program. During the specified warranty period, if the module is found to have defects in materials or workmanship, GE Fanuc will provide repair or replacement services free of charge. Their technical support team is readily available to assist customers with any installation – related queries, troubleshooting complex issues, or providing advice on optimizing the module’s performance. This commitment to quality and customer service reflects GE Fanuc’s confidence in the IC660TSA100 and its ability to perform reliably in diverse industrial applications, giving customers peace of mind when using this product in their automation setups.