Description

Product Overview

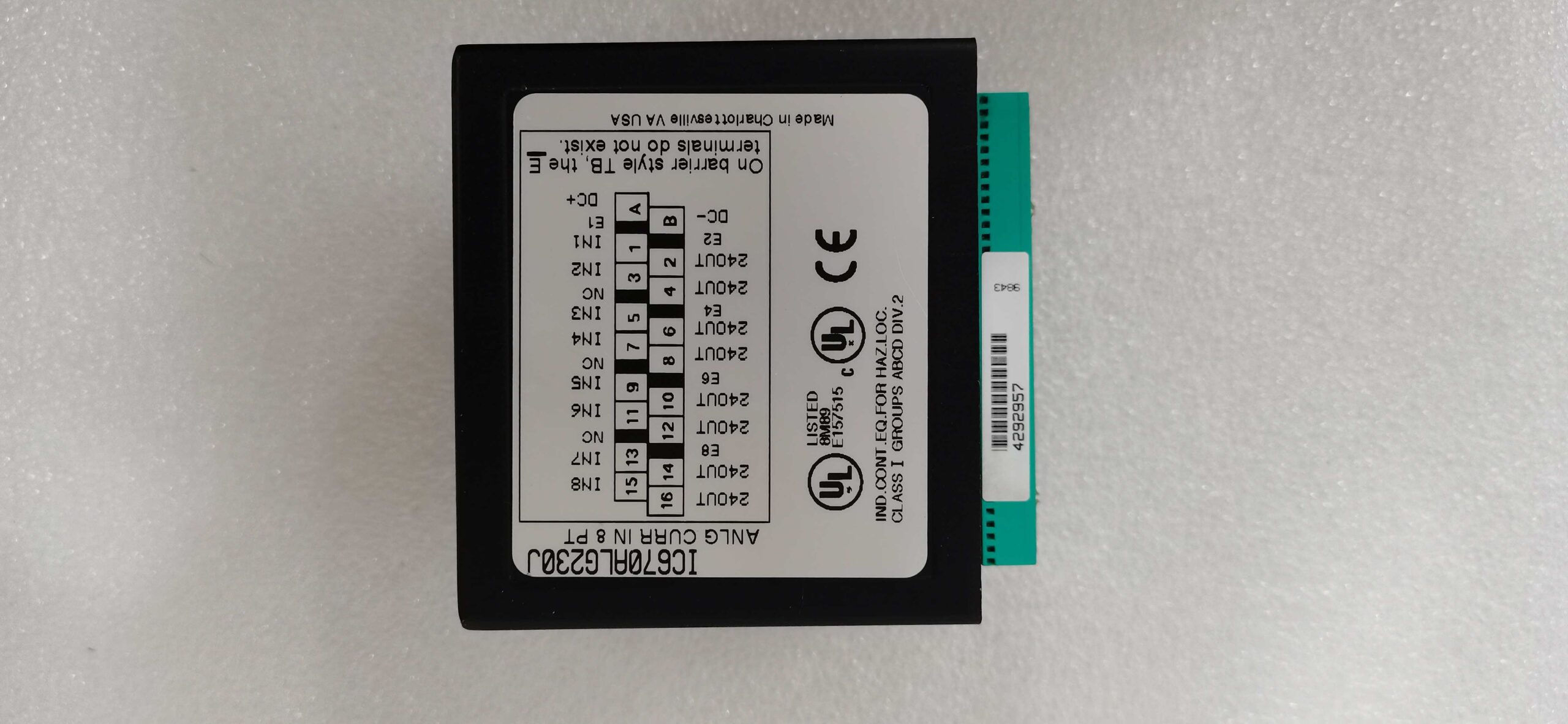

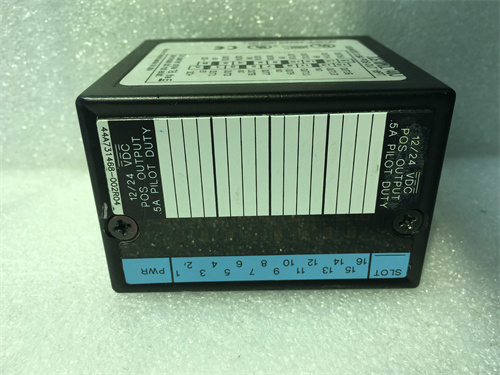

The GE IC670MDL930J is a high – performance discrete output module developed by General Electric, a well – known name in industrial automation. It is engineered specifically for field control applications, playing a crucial role in industrial automation systems.

This module’s core function is to accurately and reliably control the output signals in industrial setups. With its advanced design, it can precisely manage a wide range of industrial tasks. It is part of GE’s comprehensive lineup of products that are designed to enhance the efficiency and reliability of industrial processes. In an automation system, the GE IC670MDL930J is positioned as a key component for ensuring that the control commands are effectively executed. Its value lies in providing a stable and accurate output, which is essential for the seamless operation of various industrial equipment. Whether it’s controlling motors, valves, or other actuators, the IC670MDL930J offers the precision and reliability needed for smooth industrial automation.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC670MDL930J |

| Manufacturer | General Electric |

| Product Type | Discrete Output Module |

| Number of Outputs | 16 |

| Output Voltage Range | 9.2 – 29.5 volts DC |

| Communication Protocol | Modbus |

| Operating Temperature Range | – 20 °C to + 60 °C |

| Power Consumption | 1.5W |

| Dimensions | 2.6 x 4.4 x 1.4 inches |

| Weight | 0.3 lbs |

| Memory Capacity | Up to 1 MB of non – volatile memory |

| Connectivity Interface | Supports RS – 485 |

IC670MDL740J

Main Features and Advantages

High – precision control: The GE IC670MDL930J is capable of providing highly precise control over output signals. With 16 discrete outputs, it can handle complex control scenarios in industrial applications with great accuracy. This precision ensures that the connected equipment, such as motors and valves, operate exactly as required, leading to improved product quality and process efficiency.

Wide voltage compatibility: It has an output voltage range of 9.2 – 29.5 volts DC, making it compatible with a variety of industrial power sources. This versatility allows it to be easily integrated into different industrial setups without the need for extensive power – conversion modifications, saving both time and cost during system installation.

Reliable operation in diverse environments: The module can operate within a temperature range of – 20 °C to + 60 °C. This wide temperature tolerance makes it suitable for use in various industrial environments, from cold storage facilities to hot manufacturing plants. Its ability to withstand different temperatures ensures continuous and reliable operation, minimizing the risk of system failures due to environmental factors.

Efficient communication: Equipped with an RS – 485 communication interface, the IC670MDL930J enables seamless data exchange. This feature enhances system integration and monitoring capabilities, allowing operators to easily monitor and control the module’s performance and the overall industrial process in real – time.

Wide voltage compatibility: It has an output voltage range of 9.2 – 29.5 volts DC, making it compatible with a variety of industrial power sources. This versatility allows it to be easily integrated into different industrial setups without the need for extensive power – conversion modifications, saving both time and cost during system installation.

Reliable operation in diverse environments: The module can operate within a temperature range of – 20 °C to + 60 °C. This wide temperature tolerance makes it suitable for use in various industrial environments, from cold storage facilities to hot manufacturing plants. Its ability to withstand different temperatures ensures continuous and reliable operation, minimizing the risk of system failures due to environmental factors.

Efficient communication: Equipped with an RS – 485 communication interface, the IC670MDL930J enables seamless data exchange. This feature enhances system integration and monitoring capabilities, allowing operators to easily monitor and control the module’s performance and the overall industrial process in real – time.

IC670MDL640

Application Field

Manufacturing industry: In manufacturing plants, the GE IC670MDL930J is used to control the operation of production line equipment. For example, it can control the movement of robotic arms by sending precise output signals. It also manages the opening and closing of valves in fluid – handling systems, ensuring the accurate flow of materials during the manufacturing process. This helps in maintaining the quality and speed of production.

Power generation: In power plants, the module plays a role in controlling the operation of various electrical equipment. It can be used to control the switching of circuit breakers, ensuring the safe and efficient distribution of electricity. Additionally, it can manage the operation of pumps and fans in cooling systems, maintaining the proper temperature and pressure conditions for power generation equipment.

Water treatment facilities: In water treatment plants, the IC670MDL930J is used to control the operation of pumps, valves, and other equipment involved in the water treatment process. It can accurately regulate the flow of water, chemicals, and sludge, ensuring that the water treatment process is carried out effectively and that the treated water meets the required quality standards.

Power generation: In power plants, the module plays a role in controlling the operation of various electrical equipment. It can be used to control the switching of circuit breakers, ensuring the safe and efficient distribution of electricity. Additionally, it can manage the operation of pumps and fans in cooling systems, maintaining the proper temperature and pressure conditions for power generation equipment.

Water treatment facilities: In water treatment plants, the IC670MDL930J is used to control the operation of pumps, valves, and other equipment involved in the water treatment process. It can accurately regulate the flow of water, chemicals, and sludge, ensuring that the water treatment process is carried out effectively and that the treated water meets the required quality standards.

Related Products

- GE IC670MDL940J: Another discrete output module by GE. It may have different output characteristics, such as a different number of outputs or a different voltage range. It could be used in applications where the IC670MDL930J‘s specifications do not fully meet the requirements, or in systems where multiple types of discrete output modules are needed for different control tasks.

- GE IC693MDL940: This is also a module in GE’s product range. It might be part of a different series but serves a similar purpose in terms of providing control functions. It could have enhanced features or be designed for more specific industrial applications compared to the IC670MDL930J.

- GE PLC Controllers: These controllers are used in conjunction with the IC670MDL930J to manage and coordinate the overall control logic. They send commands to the module, which then executes the appropriate output actions. Different models of GE PLC controllers can be selected based on the complexity and scale of the industrial automation system.

- Communication Modules for GE Systems: Modules like those supporting Ethernet/IP or Devicenet protocols can be used with the IC670MDL930J to expand its communication capabilities beyond the basic RS – 485. They enable the module to communicate with a wider range of devices and systems, enhancing the overall connectivity and integration of the industrial automation setup.

- Power Supply Modules for GE Equipment: Specific power supply modules are designed to provide the necessary power to the IC670MDL930J. They ensure a stable power source, which is crucial for the reliable operation of the module. Different power supply modules may have different power ratings and features to meet the requirements of various industrial environments.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IC670MDL930J, ensure that the installation environment meets the specified temperature and humidity requirements, with a temperature range of – 20 °C to + 60 °C. Check the power supply voltage to confirm it is within the 9.2 – 29.5 volts DC range. Prepare the necessary tools for installation, such as screwdrivers. Make sure the communication interface, like the RS – 485 connection, is properly configured and free from any physical damage. Also, verify that the module is compatible with the existing industrial automation system in terms of communication protocols and overall system architecture.

Maintenance recommendations: Regularly monitor the GE IC670MDL930J‘s operating temperature to ensure it remains within the specified range. Check the output signals periodically to confirm they are accurate and consistent. Clean the module to remove any dust or debris that could affect its performance. If any issues arise, refer to the product manual for troubleshooting steps. For example, if there are communication problems, check the RS – 485 cable connections and the communication settings. In case of hardware failures, contact GE’s technical support for guidance on replacement or repair procedures.

Maintenance recommendations: Regularly monitor the GE IC670MDL930J‘s operating temperature to ensure it remains within the specified range. Check the output signals periodically to confirm they are accurate and consistent. Clean the module to remove any dust or debris that could affect its performance. If any issues arise, refer to the product manual for troubleshooting steps. For example, if there are communication problems, check the RS – 485 cable connections and the communication settings. In case of hardware failures, contact GE’s technical support for guidance on replacement or repair procedures.

Product Guarantee

General Electric provides a comprehensive product guarantee for the GE IC670MDL930J. The module is manufactured with high – quality materials and under strict quality control processes to ensure its reliability and performance. In the event of any defects in materials or workmanship during the warranty period, GE offers repair or replacement services. Their team of technical experts is available to provide support for installation, configuration, and troubleshooting. This demonstrates GE’s confidence in the quality of the IC670MDL930J and its commitment to customer satisfaction, ensuring that customers can rely on this module for their industrial automation needs.