Description

Product Overview

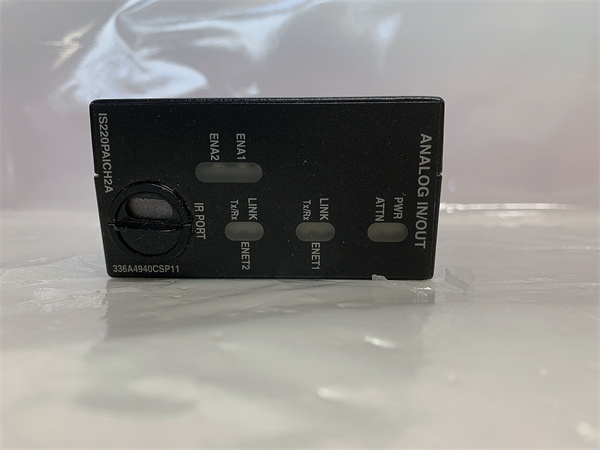

The GE IC693CMM321 is an Ethernet interface module that is an integral part of the Series 90 – 30 programmable logic controller (PLC) platform by GE Fanuc. It serves as a crucial link in industrial automation systems, enabling seamless communication between the Series 90 – 30 baseplate and existing Ethernet networks. This module is designed to facilitate distributed I/O implementation, allowing for efficient control and monitoring of industrial processes.

With its advanced features, the GE IC693CMM321 can support up to three ports, providing versatile connectivity options. It enables communication between various components such as CPUs, communication adapters, remote stations, human – machine interfaces (HMIs), supervisory control and data acquisition (SCADA) systems, and distributed control systems (DCS). By ensuring reliable data exchange, it plays a vital role in maintaining the smooth operation of industrial automation setups, enhancing productivity and reducing the risk of system failures.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC693CMM321 |

| Manufacturer | GE |

| Product Type | Ethernet Interface Module |

| Connection Accessories | AUI Cable |

| External Transceiver | Available |

| Number of Ports | 3 |

| Number of LED Indicators | 4 |

| Module Width | Single Slot |

| Power Supply | 5 V DC from the Series 90 – 30 backplane |

| Current Consumption | < 300 mA at +5 V DC |

| Compatible CPU | Version 6.50 or higher (full functionality); versions 5.03 to 6.04 (1 SRTP connection only) |

| Supported Operations | Client and Server device operations |

Main Features and Advantages

Reliable Communication

The GE IC693CMM321 is engineered to deliver highly reliable communication. It minimizes data transfer errors and disruptions, ensuring stable and consistent communication within industrial automation systems. This reliability is crucial for applications where continuous and accurate data exchange is essential, such as in real – time process control.

Versatile Connectivity

Featuring three ports, this module offers extensive network connectivity options. It can be easily connected to a variety of devices and remote systems using AUI cables and external transceivers. This versatility allows for seamless integration into different industrial setups, adapting to the specific requirements of each application.

Compact Design

With its single – slot width design, the GE IC693CMM321 optimizes space within control cabinets. This is especially beneficial in applications where space is limited, enabling efficient use of available space without sacrificing functionality.

Low Power Consumption

Consuming less than 300 mA at +5 V DC, the module is energy – efficient. This not only helps in reducing operational costs but also contributes to a more sustainable industrial automation solution. Lower power consumption also means less heat generation, enhancing the overall reliability and lifespan of the module.

High – Speed Data Transfer

It enables high – speed data exchange, which is essential for real – time monitoring and control of automated processes. The fast data transfer capabilities ensure that the automation system can respond promptly to changing conditions, improving the overall performance and efficiency of industrial operations.

IS220PDIAH1A

Application Field

In manufacturing industries, the GE IC693CMM321 is widely used to connect PLCs with production equipment. For example, in an automotive assembly plant, it links the PLC controlling robotic arms to the SCADA system. This connection allows for real – time monitoring and control of the production line, optimizing the assembly process and ensuring high – quality output.

In process control industries like chemical and power plants, the module plays a critical role. It facilitates communication between different control systems, ensuring the stable operation of the production process. In a chemical plant, it can connect the DCS with various sensors and actuators, enabling precise control of chemical reactions and the safe transfer of materials.

In material handling applications, such as in warehouses and logistics centers, the GE IC693CMM321 connects PLCs controlling conveyor belts, cranes, and other equipment to the central control system. This integration optimizes the material flow, improving the overall operational efficiency and reducing the likelihood of errors in material handling.

Related Products

- IC693CPU311: A central processing unit for the Series 90 – 30 PLC system. It works in tandem with the GE IC693CMM321 to execute control programs and manage communication, with the CPU handling the computational tasks while the IC693CMM321 enables network connectivity.

- IC693MDL940: An I/O module that can be integrated into the system with the GE IC693CMM321. It expands the input and output capabilities of the PLC system, allowing it to interface with more field devices. The IC693CMM321 provides the network connection for data transfer related to these I/O operations.

- IC697CMM731: Another Ethernet interface module in the GE product line. While it shares the function of providing Ethernet connectivity, it may have different features such as higher port speeds or additional communication protocol support, making it suitable for different application requirements compared to the GE IC693CMM321.

- IC693ACC302: An accessory module that can enhance the functionality of the GE IC693CMM321. It may provide additional connection options or features, like extra ports or improved signal conditioning for the Ethernet connection.

- IC693PWR321: A power supply module that powers the GE IC693CMM321 and other modules in the Series 90 – 30 system. It ensures stable power supply for the IC693CMM321 to function properly and maintain reliable communication.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IC693CMM321 module, make sure the Series 90 – 30 backplane is correctly configured and powered off. Check the compatibility of the module with the existing CPU version. The installation area should be clean, free from dust and debris that could affect the module’s performance. Also, ensure that the AUI cables and any external transceivers are in good condition and properly selected for the intended application.

Maintenance recommendations: Regularly monitor the status of the GE IC693CMM321 through its LED indicators. These indicators can provide valuable information about the module’s operation, such as network connectivity and port activity. If any abnormalities are detected, refer to the user manual for troubleshooting steps. Keep the module clean and free from dust and moisture, as these can cause electrical problems over time. Periodically update the module’s firmware to ensure it operates optimally and is compatible with the latest software and hardware in the system.

Maintenance recommendations: Regularly monitor the status of the GE IC693CMM321 through its LED indicators. These indicators can provide valuable information about the module’s operation, such as network connectivity and port activity. If any abnormalities are detected, refer to the user manual for troubleshooting steps. Keep the module clean and free from dust and moisture, as these can cause electrical problems over time. Periodically update the module’s firmware to ensure it operates optimally and is compatible with the latest software and hardware in the system.

Product Guarantee

GE stands firmly behind the quality of the GE IC693CMM321. The module is manufactured to meet high – quality standards, with strict quality control measures in place during production. In case of any manufacturing defects, GE offers a comprehensive after – sales service. This includes a warranty that covers repair or replacement of the module within the specified warranty period. GE’s technical support team is readily available to assist customers. Whether it’s answering technical queries, providing installation guidance, or helping with troubleshooting, GE is committed to ensuring the smooth operation of the GE IC693CMM321 in industrial automation systems, giving customers confidence in their investment.