Description

Product Overview

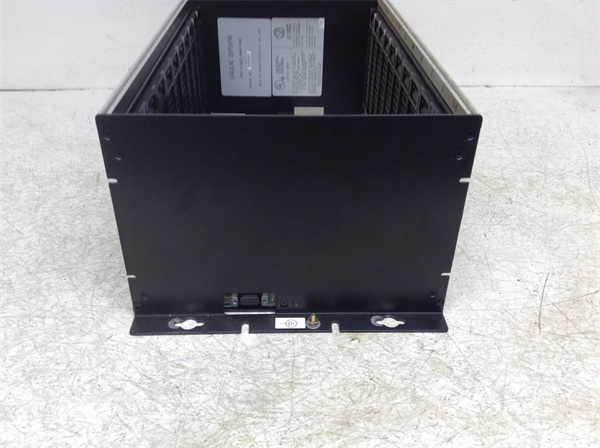

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC697CHS790D |

| Manufacturer | GE |

| Product Type | 9 – slot Rear – mount PLC Rack |

| Number of Slots | 9 (plus 1 power slot) |

| Dimensions | 11.15H x 19W x 7.5D (283 mm x 483 mm x 190 mm) |

| Weight | Approximately 7.00 lbs |

| Input Voltage | Compatible with 120 VAC (with IC697ACC721 fan component), 240 VAC (with IC697ACC724), 24 VDC (with IC697ACC744) |

| Backplane Power | Rated 20 A, 5 VDC |

| I/O Expansion | Supports expansion, 2 racks can share power module |

| Compatibility | All IC697 PLC modules |

| Mounting Type | Rear – mount |

| Communication | Allows connection to communication adapter or CPU through 背板 |

| Mechanical Feature | Mechanical interlock to prevent module mis – installation |

GE IC697CHS790D

Main Features and Advantages

Scalability: The ability to expand I/O and share power between two racks makes the GE IC697CHS790D highly scalable. As industrial operations grow or change, additional I/O modules can be added, ensuring the system can keep up with increasing demands. This scalability reduces the need for frequent system overhauls, saving both time and money.

Compatibility: Its compatibility with all IC697 PLC modules simplifies system integration. Engineers can choose from a wide range of modules based on the specific requirements of the industrial process. Whether it’s digital input/output modules, analog input/output modules, or communication modules, they can all be easily installed and integrated into the system.

Mechanical Interlock: The mechanical interlock feature is a crucial safety aspect. It prevents accidental or unauthorized swapping of modules, reducing the risk of system malfunctions due to incorrect module installation. This ensures the stable and reliable operation of the industrial control system, especially in environments where human error could have significant consequences.

Compact Design: Despite its high functionality, the IC697CHS790D has a compact design. Its relatively small dimensions make it suitable for installation in areas with limited space, such as control panels in factories or power plants. This compactness also contributes to better space utilization in industrial setups.

Application Field

In the manufacturing industry, the GE IC697CHS790D is widely used in factory automation. It can be the core of a control system that manages the operation of robotic arms, conveyor belts, and other manufacturing equipment. By connecting and coordinating various I/O modules, it enables precise control over the manufacturing process, improving product quality and production efficiency.

In the energy sector, particularly in power plants, the rack is used to control and monitor the generation, distribution, and transmission of electricity. It can interface with sensors and actuators that monitor parameters such as temperature, pressure, and voltage in power generation equipment. The data collected through I/O modules is processed, and appropriate control signals are sent to ensure the stable operation of the power plant.

For the transportation industry, especially in automated transportation systems like those in ports or airports, the IC697CHS790D plays a vital role. It can control the movement of automated guided vehicles (AGVs), manage the operation of conveyor systems for luggage handling, or regulate the access control systems. In all these applications, the rack’s reliability and scalability are essential for ensuring smooth and efficient transportation operations.

Even in environmental monitoring and control systems, such as wastewater treatment plants, the GE IC697CHS790D is utilized. It can connect to sensors that measure the quality of water, the level of pollutants, and other relevant parameters. Based on the data received through I/O modules, it can control the operation of pumps, valves, and treatment equipment to ensure that wastewater is treated effectively and meets environmental standards.

GE IC697CHS790D

Related Products

- GE IC697ACC721: This is a rack – mounted fan component specifically designed for use with the IC697CHS790D when the power supply is 120 VAC. It helps in cooling the rack and its installed modules, ensuring optimal operating temperatures and enhancing the lifespan of the components.

- GE IC697ACC724: Similar to the IC697ACC721, but it is used when the power supply for the IC697CHS790D is 240 VAC. It also provides essential cooling functionality for the rack in high – voltage power supply setups.

- GE IC697ACC744: For the IC697CHS790D operating on a 24 VDC power supply, this fan component is the appropriate choice. It maintains the proper temperature within the rack, which is crucial for the reliable operation of the PLC modules installed in the IC697CHS790D.

- GE IC697 – series PLC modules: These are the various PLC modules that are compatible with the IC697CHS790D. They include digital input/output modules for controlling and monitoring digital signals, analog input/output modules for handling analog data from sensors and actuators, and communication modules for enabling communication with other devices in the industrial network.

- GE 90 – 70 series accessories: There are other accessories in the 90 – 70 series that can be used in conjunction with the IC697CHS790D. These may include mounting brackets, cable management systems, or additional power distribution units that can further enhance the functionality and installation convenience of the rack in an industrial control system.

Installation and Maintenance

Maintenance recommendations: Regularly inspect the IC697CHS790D for any physical damage, such as cracks in the rack or loose connections. Check the operation of the fan components (IC697ACC721, IC697ACC724, or IC697ACC744) to ensure proper cooling. Monitor the temperature inside the rack to ensure it remains within the recommended range. Periodically clean the rack and its modules to remove dust and debris, which can affect performance. Check for any firmware updates for the installed modules and the rack itself, as these can improve functionality and fix any known issues. In case of any problems, contact GE’s technical support or an authorized service center for proper troubleshooting and repair.