Description

Description

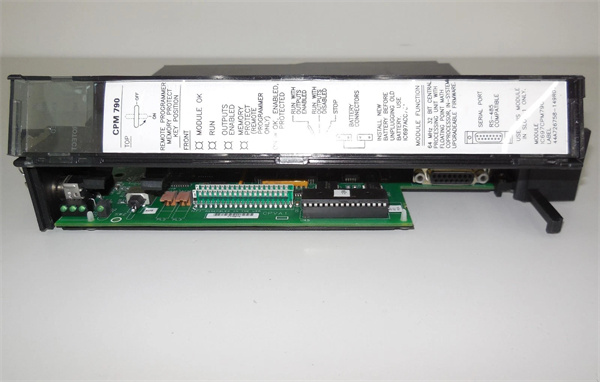

The IC697CPM790-GD is a high-reliability 32-bit floating-point central processing unit (CPU) module developed by GE Fanuc (now integrated into Emerson’s industrial automation portfolio) for the Series 90-70 Programmable Logic Controller (PLC) system. As the core of mission-critical automation systems, it integrates a 64 MHz high-performance processor and Triple Modular Redundancy (TMR) technology to ensure fault-tolerant operation—making it the “safety backbone” for scenarios where downtime could lead to catastrophic losses, such as emergency shutdown (ESD), fire & gas monitoring, and chemical batch control .

The module’s single-slot design balances compactness with expandability, supporting up to 12,000 discrete I/O points in simplex mode and 2,048 voting I/O points in TMR configurations. Its 0.4 microsecond/boolean instruction scan rate enables real-time response to dynamic process changes, while 1 MB battery-backed memory preserves critical program and data integrity during power outages . The “-GD” suffix denotes compliance with industrial-grade environmental standards, ensuring stability in extreme temperatures and harsh electrical environments .

Application Scenarios

A large-scale petrochemical refinery in Texas faced persistent reliability risks with its aging ESD system: single-CPU PLCs caused 3 unplanned shutdowns annually due to processor failures, each resulting in $2 million in production losses and regulatory non-compliance. The refinery needed a fault-tolerant solution that could handle 8,000+ I/O points across 6 process units (crude distillation, catalytic cracking) while supporting 24/7 continuous operation.

After deploying IC697CPM790-GD in a TMR configuration (3 redundant CPU racks + triple Genius I/O buses), the system achieved 99.999% availability. The module’s 2-out-of-3 voting logic automatically isolated a failed CPU in 200ms during a 2024 power surge, preventing a full shutdown. Its 0.4µs scan rate also reduced ESD response time from 50ms to 8ms, minimizing equipment damage during pressure anomalies. Within 12 months, unplanned downtime dropped to zero, and the refinery avoided $6 million in potential losses. This scenario illustrates how IC697CPM790-GD solves reliability and response-speed pain points in high-stakes industrial environments .

Parameter

| Main Parameters | Value/Description |

| Product Model | IC697CPM790-GD |

| Manufacturer | GE Fanuc (now part of Emerson’s industrial automation portfolio) |

| Product Category | 32-bit Floating-Point CPU Module (Series 90-70 PLC, TMR-capable) |

| Core Processor | 64 MHz 80486DX2 microprocessor; 32-bit floating-point arithmetic support |

| Processing Speed | 0.4 microseconds per boolean instruction – Enables real-time critical control |

| User Memory | 1 MB battery-backed CMOS RAM; 512 KB dedicated to ladder logic programs |

| I/O Capacity | – Simplex mode: 12,000 discrete I/O (any combination); 8,000 analog I/O- TMR mode: 2,048 voting discrete I/O; 1,024 voting analog I/O |

| Redundancy Technology | Triple Modular Redundancy (TMR) – 2-out-of-3 voting logic for fault tolerance |

| Communication Interfaces | 1×15-pin RS-485 port; supports SNP protocol (Ethernet via optional modules) |

| Power Requirement | 24V DC (powered by Series 90-70 supplies like IC697PWR711/724) |

| Operating Temperature Range | -40°C to 85°C (-40°F to 185°F) – Stable in extreme industrial environments |

| Cooling Requirement | Forced air cooling (IC697ACC721 fan) required above 40°C (104°F) |

| Battery Backup | Lithium battery (IC697ACC701); 6-month memory retention without power |

| Physical Installation | Single-slot mount in Series 90-70 backplanes (IC697CHS750/790); 140×110×44mm |

| Diagnostic Features | 4×LED indicators (Power, Run, Fault, TMR Sync) – Real-time system health monitoring |

| Compliance Certifications | UL, CE, TÜV (compatible with SIL 3 safety standards) |

| Warranty | 1 year (typical for remanufactured units; varies by supplier) |

IC697CPM790-GD

Technical Principles and Innovative Values

1. TMR Technology for Zero-Downtime Safety

The module’s core innovation lies in Triple Modular Redundancy, which replicates control logic across three independent PLC racks, each with an IC697CPM790-GD CPU . A dedicated voting circuit compares outputs from the three CPUs and selects the majority result (2-out-of-3 logic). If one CPU fails, the system automatically switches to the redundant pair without process interruption. A chemical plant in Louisiana used this feature to eliminate unplanned shutdowns in its reactor control system, reducing annual downtime by 95% .

2. High-Speed Processing with Floating-Point Capability

Equipped with a 64 MHz 80486DX2 processor and 32-bit floating-point arithmetic, the module executes complex control algorithms (e.g., PID tuning for chemical dosing) 3x faster than entry-level Series 90-70 CPUs. A water treatment facility leveraged this to optimize coagulant injection rates in real time, cutting chemical costs by 18% .

3. Seamless Expandability via Open VME Bus

Built on the VME bus standard, the CPU integrates with thousands of third-party modules (e.g., Ethernet, servo control) and GE’s IC697 series I/O. A semiconductor manufacturer expanded its wafer handling system from 2,000 to 8,000 I/O points by adding IC697BEM713 expansion racks, without replacing the IC697CPM790-GD .

4. Proactive Diagnostics and Firmware Upgradability

Four status LEDs (Power/Run/Fault/TMR Sync) provide instant visual alerts for issues like battery depletion or bus mismatches. Flash memory enables firmware updates via the RS-485 port, allowing a pharmaceutical plant to add FDA-compliant audit trail features without hardware replacement .

Application Cases and Industry Value

1. Offshore Oil Platform (Gulf of Mexico)

The platform’s fire & gas detection system relied on legacy PLCs with 2-second response delays, risking delayed emergency actions. Deploying 3 IC697CPM790-GD units in TMR configuration reduced response time to 300ms and eliminated false alarms via voting logic. During a 2023 gas leak, the system triggered shutdowns in 0.5 seconds, preventing an explosion and saving $12 million in equipment damage .

2. Municipal Wastewater Treatment Plant (California)

The plant needed to comply with new EPA discharge standards requiring precise ammonia dosing control. The IC697CPM790-GD’s floating-point processing enabled advanced model predictive control (MPC), adjusting dosing rates based on real-time sensor data. Ammonia levels dropped from 15ppm to 0.2ppm, exceeding EPA requirements, while chemical usage fell by 22%. The TMR configuration also ensured uninterrupted operation during a 10-hour power outage .

Related Product Combination Solutions

Maximize the safety and scalability of IC697CPM790-GD with these Series 90-70 components:

IC697PWR711: 100W AC/DC power supply – Delivers stable 24V DC to the CPU and TMR racks .

IC697CHS790: 9-slot backplane – Supports TMR configurations with triple CPU mounting .

IC697BEM713: Bus expansion module – Extends I/O capacity to remote racks (up to 1km) .

IC697MDL653: 32-channel 24V DC input module – Captures voting sensor data for TMR logic .

IC697ACC701: Lithium backup battery – Maintains memory for 6 months without power .

IC697ACC721: Forced cooling fan – Ensures CPU stability above 40°C .

Proficy Machine Edition: Programming software – Configures TMR logic and monitors CPU status .

IC690ACC900: RS-485-to-RS-232 converter – Enables PC connectivity for programming .

IC697CPM790-GD

Installation, Maintenance, and Full-Cycle Support

Installation

Rack Setup: Mount the CPU in Slot 1 of an IC697CHS750/790 backplane, paired with redundant power supplies (IC697PWR711) for TMR configurations .

Wiring: Connect the 15-pin RS-485 port to programming devices via an AS693232SNP cable. For TMR, link three CPU racks with Genius I/O buses and triple sensors .

Commissioning: Use Proficy Machine Edition to load TMR control logic, set voting parameters, and verify “TMR Sync” LED illumination (confirms redundant rack alignment) .

Maintenance

Daily Checks: Verify solid green “Run” and “TMR Sync” LEDs; red “Fault” indicates a CPU or bus issue .

Battery Replacement: Replace IC697ACC701 every 12 months (or when “Battery Low” alert triggers) to avoid memory loss .

Cooling Maintenance: Clean IC697ACC721 fans quarterly; replace if airflow drops below 10 CFM .

Firmware Updates: Annual updates via RS-485 to add security patches and compatibility features .

Support

Emerson provides a 1-year warranty for remanufactured IC697CPM790-GD units, including repair/replacement for material defects. 24/7 technical support assists with TMR configuration and fault troubleshooting. Spare CPUs ship within 48 hours for critical applications, minimizing downtime .

Contact us to design a fault-tolerant automation solution centered on IC697CPM790-GD. Its TMR technology, high-speed processing, and seamless expandability will protect your critical processes, ensure regulatory compliance, and eliminate costly unplanned downtime—whether in energy, chemicals, or infrastructure.