Description

Description

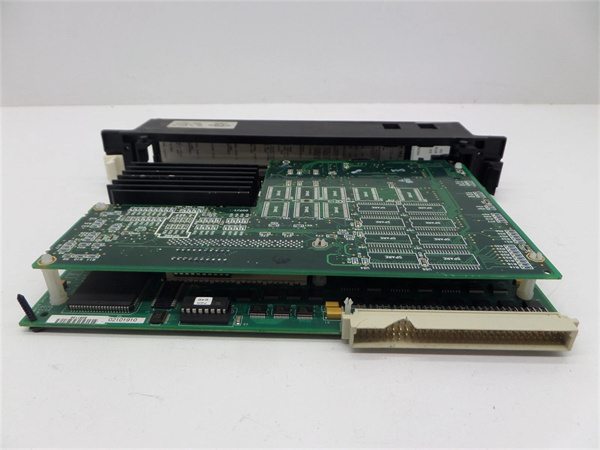

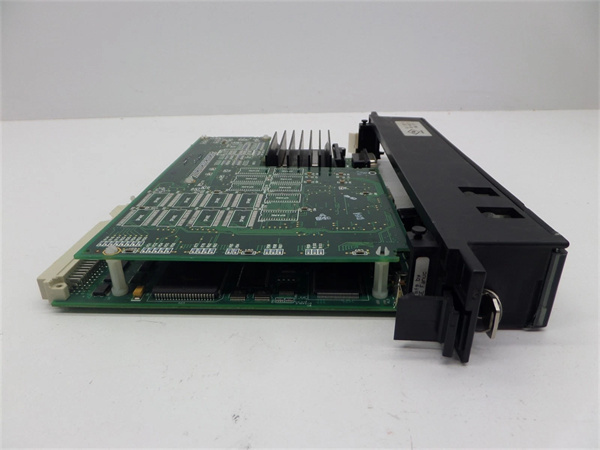

The IC697CPX928-CD is a high-performance 32-bit central processing unit (CPU) module developed by GE Fanuc (now part of Emerson’s industrial automation portfolio) for the Series 90-70 Programmable Logic Controller (PLC) system. As the “processing core” of medium-to-large industrial automation systems, it integrates a 96 MHz 80486DX4 microprocessor and advanced memory architecture to deliver fast logic execution and reliable data management—making it ideal for scenarios requiring high I/O capacity and complex calculations, such as manufacturing production lines, process control systems, and energy management networks .

The “-CD” suffix denotes compliance with industrial-grade configuration standards, emphasizing its stability in harsh electrical environments and compatibility with extended temperature ranges. The module features a single-slot design for space efficiency, 6 MB battery-backed RAM for critical data retention, and 256 KB non-volatile flash memory for firmware and program storage. With three built-in serial ports (1×RS-232, 2×RS-485) and support for optional Ethernet modules, it enables seamless integration with HMI, sensors, and third-party devices . Its 0.4 microsecond/boolean instruction scan rate ensures real-time response to dynamic process changes, while compatibility with 12,000 mixed I/O points and 8,000 analog I/O points provides exceptional scalability .

Application Scenarios

A mid-sized automotive component manufacturer in Ohio faced production inefficiencies with its aging PLC system: the existing CPU had a 1.2µs scan rate and limited I/O capacity, causing delays in coordinating 6 robotic assembly stations and 5,000+ I/O points (e.g., proximity sensors, servo drives). Changeovers between 12 product variants required 2–3 hours of manual programming, leading to 15% annual downtime and 2.8% defective parts.

After upgrading to the IC697CPX928-CD, the manufacturer achieved a 67% reduction in scan time (0.4µs/boolean instruction), enabling synchronized control of robotic arms and conveyor systems. The module’s 6 MB RAM supported pre-stored recipe parameters for all 12 product variants, cutting changeover time to 30 minutes. Its dual RS-485 ports simplified daisy-chaining of 20+ barcode scanners, reducing wiring complexity by 50%. Within 6 months, unplanned downtime dropped to 3%, defect rates fell to 0.7%, and annual production output increased by 12%. This scenario highlights how the IC697CPX928-CD solves scalability and speed bottlenecks in high-volume manufacturing .

Parameter

| Main Parameters | Value/Description |

| Product Model | IC697CPX928-CD |

| Manufacturer | GE Fanuc (now part of Emerson’s industrial automation portfolio) |

| Product Category | 32-bit PLC CPU Module (Series 90-70, industrial-grade configuration) |

| Core Processor | 96 MHz 80486DX4 microprocessor; 32-bit floating-point arithmetic support |

| Processing Speed | 0.4 microseconds per boolean instruction – Enables real-time control response |

| User Memory | – 6 MB battery-backed CMOS RAM (data/program retention)- 256 KB non-volatile flash memory (firmware/programs) |

| I/O Capacity | – 12,000 mixed discrete/analog I/O points- 8,000 dedicated analog I/O points |

| Communication Interfaces | 1×RS-232 serial port, 2×RS-485 serial ports, 1×factory reset port; supports SNP, RTU, SNPX protocols |

| Expansion Support | Compatible with Ethernet modules, coprocessors, bus controllers, and IC697 I/O modules |

| Power Requirement | 5 V DC, 3.1 A (powered by Series 90-70 supplies like IC697PWR711) |

| Operating Temperature Range | – Forced air cooling (70 CFM): 0°C–60°C (32°F–140°F)- No forced cooling: 0°C–50°C (32°F–122°F) |

| Battery Backup | Lithium CMOS battery (IC697ACC701); maintains RAM for 6+ months without power |

| Physical Installation | Single-slot mount in Series 90-70 backplanes (e.g., IC697CHS750/790); 140×110×44mm |

| Diagnostic Features | 7×LED indicators (Power, Run, Fault, Memory, Communication) – Real-time status monitoring |

| Compliance Certifications | UL, CE (industrial safety and electromagnetic compatibility) |

IC697CPX928-CD

Technical Principles and Innovative Values

1. High-Speed Processing with Floating-Point Capability

The 96 MHz 80486DX4 processor delivers 0.4µs boolean instruction execution, 3x faster than entry-level Series 90-70 CPUs. Its 32-bit floating-point unit enables precise calculations for process control (e.g., PID tuning for chemical dosing), eliminating rounding errors common in 16-bit systems. A water treatment facility leveraged this to optimize coagulant injection rates, reducing chemical usage by 22% .

2. Software-Centric Configuration for Flexibility

Unlike legacy CPUs with hardware jumpers/DIP switches, the IC697CPX928-CD is fully configured via software (MS-DOS or Windows-based tools like Proficy Machine Edition) over Ethernet or serial ports. This eliminates physical hardware adjustments during system upgrades, cutting reconfiguration time by 80%. A food packaging plant used this feature to remotely update recipe parameters, avoiding 4 hours of monthly downtime .

3. Multi-Protocol Communication for Seamless Integration

Dual RS-485 ports support daisy-chaining of up to 32 devices each (e.g., sensors, drives) via SNP/RTU protocols, while the RS-232 port enables direct programming. Optional Ethernet modules add support for TCP/IP, enabling integration with MES systems. An automotive plant used this to connect the CPU to a cloud-based production dashboard, reducing data latency from 5 minutes to 10 seconds .

4. Rugged Design for Industrial Reliability

The module’s wide operating temperature range and 70 CFM forced air cooling support make it stable in hot factory cabinets. Its battery-backed RAM retains critical data (e.g., production counts, fault logs) during power outages, ensuring seamless restart. A chemical plant reported zero CPU failures over 3 years despite temperature fluctuations from 10°C to 55°C .

Application Cases and Industry Value

1. Chemical Batch Plant (Texas)

The plant’s 8 reaction vessels required precise temperature/pressure control and batch parameter logging. Legacy CPUs struggled with 8,000 analog I/O points, causing 3% batch rejection. Deploying IC697CPX928-CD enabled real-time monitoring of 120 sensors and execution of complex batch logic. Flash memory stored 50+ batch recipes, cutting changeover time by 75%. Rejection rates dropped to 0.5%, saving $400,000 annually .

2. Municipal Power Distribution (California)

A utility company needed to manage 10,000+ I/O points across 20 substations (e.g., voltage sensors, circuit breakers). The IC697CPX928-CD’s RS-485 ports connected to remote I/O racks via Modbus RTU, enabling centralized control. Its fast scan rate reduced fault detection time from 2 seconds to 300ms, minimizing power outages by 40%. The utility avoided $1.2 million in annual downtime costs .

Related Product Combination Solutions

Maximize the scalability of IC697CPX928-CD with these Series 90-70 components:

IC697PWR711: 100W AC/DC power supply – Delivers stable 5V DC to the CPU and I/O modules .

IC697CHS790: 9-slot backplane – Provides physical and electrical connectivity for the CPU and expansion modules .

IC697BEM713: Bus expansion module – Extends I/O capacity to remote racks (up to 1km) .

IC697MDL653: 32-channel 24V DC input module – Captures discrete sensor data (e.g., limit switches) .

IC697ALG440: 4-channel analog input module – Monitors continuous variables (e.g., temperature, pressure) .

IC697ACC701: Lithium backup battery – Maintains RAM data for 6+ months without power .

IC697LAN925: Ethernet interface module – Adds TCP/IP connectivity for MES/HMI integration .

Proficy Machine Edition: Programming software – Configures logic, monitors status, and manages recipes .

IC697CPX928-CD

Installation, Maintenance, and Full-Cycle Support

Installation

Pre-Installation Check: Power off the Series 90-70 rack; set the CPU’s Run/Stop switch to “Stop” and memory protection key to “Off” .

Mechanical Mounting: Insert the module into any available slot in the backplane (e.g., IC697CHS790) and secure with the spring latch .

Wiring: Connect serial ports to programming devices/sensors; install the lithium battery (IC697ACC701) in the battery slot .

Commissioning: Power on the rack; use Proficy Machine Edition to detect the CPU, load logic, and verify LED status (solid green “Run” indicates normal operation) .

Maintenance

Daily Checks: Verify LED indicators (red “Fault” signals issues like low battery or communication errors) .

Battery Replacement: Replace IC697ACC701 annually or when “Battery Low” LED flashes to avoid memory loss .

Firmware Updates: Update flash memory firmware via serial/Ethernet ports (no hardware disassembly required) to add features .

Cooling Maintenance: Clean forced air fans (IC697ACC721) quarterly to maintain airflow above 70 CFM .

Support

Emerson provides a 1-year warranty for IC697CPX928-CD, covering material defects and performance issues. 24/7 technical support assists with installation, troubleshooting, and firmware upgrades. Spare modules ship within 48 hours for critical applications, minimizing downtime .

Contact us to design a high-performance automation solution centered on IC697CPX928-CD. Its fast processing, scalable I/O, and flexible communication will streamline your operations, reduce downtime, and support future expansion—whether in manufacturing, energy, or process industries.