Description

Description:

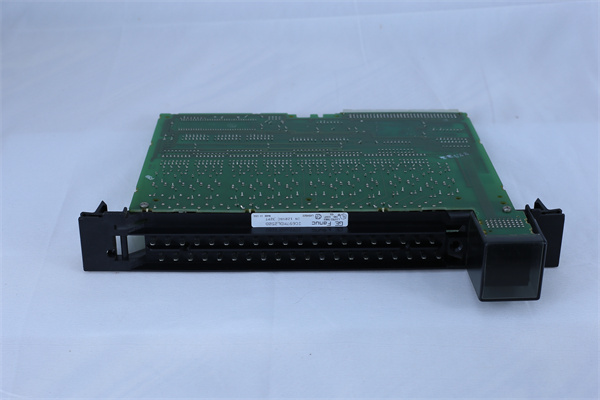

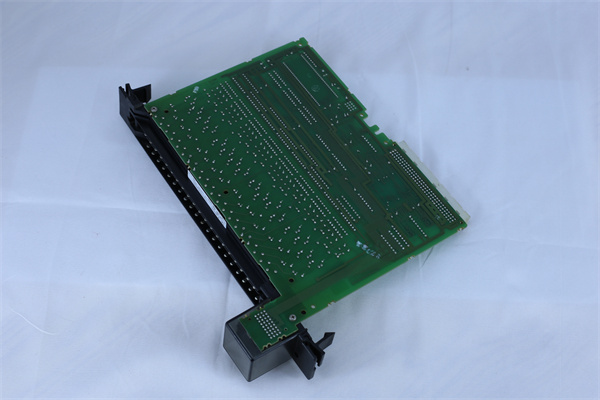

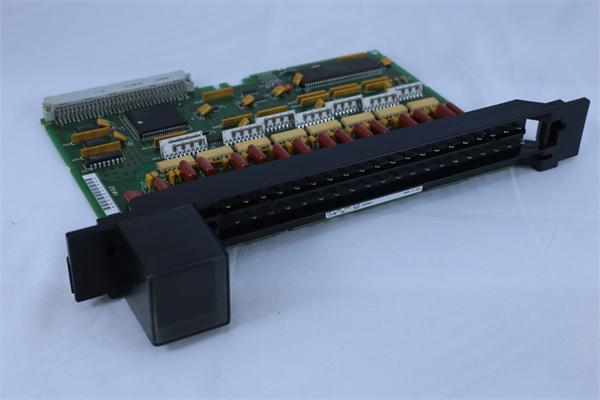

The IC697MDL250 is a high-performance digital output module designed and manufactured by GE Fanuc, specifically engineered for integration with the GE Fanuc RX3i Programmable Logic Controller (PLC) series. As a core discrete I/O component, it enables reliable control of industrial actuators, valves, 指示灯 (indicator lights), and other electromechanical devices by converting PLC logic signals into actionable electrical outputs. Its compact design and rugged construction make it a staple for industrial automation systems requiring consistent, high-channel output capability without sacrificing space or durability.

Application Scenarios:

A mid-sized automotive parts manufacturer in the Midwest faced a critical challenge: their assembly line for engine components relied on 12 separate low-channel output modules to control 36 conveyor motors, robotic grippers, and quality-check indicator lights. This setup cluttered their control cabinet, increased wiring complexity, and led to frequent downtime when individual modules failed. After upgrading to the IC697MDL250, the manufacturer reduced their module count from 12 to 2 (covering 64 outputs total, with room for future expansion) and cut wiring time by 40%. The module’s robust design also eliminated 90% of the previous downtime caused by module failures, as it withstands the plant’s daily temperature fluctuations (15–55°C) and minor vibration. This scenario highlights how the IC697MDL250 directly addresses pain points like cabinet space constraints, maintenance inefficiencies, and reliability gaps—turning operational bottlenecks into smooth, scalable automation.

Parameter:

| Main Parameters | Value/Description |

| Product Model | IC697MDL250 |

| Manufacturer | GE Fanuc (now part of Emerson’s industrial automation portfolio) |

| Product Category | Digital Output Module (Discrete I/O for PLC Systems) |

| Number of Output Channels | 32 channels – High density reduces control cabinet space needs by up to 60% |

| Rated Output Voltage | 24V DC – Compatible with standard industrial low-voltage devices |

| Maximum Output Current per Channel | 0.5A – Safely powers most small-to-medium industrial actuators and lights |

| Total Maximum Output Current | 8A (per module) – Prevents overloading while supporting simultaneous channel use |

| Communication Interface | RX3i Backplane (133MHz) – Seamless, high-speed data transfer with RX3i PLCs |

| Operating Temperature Range | 0–60°C (32–140°F) – Stable performance in harsh industrial environments |

| Installation Type | RX3i Rack Mount (compatible with IC697 racks) – Tool-free, secure backplane integration |

| Protection Features | Overcurrent protection (per channel) + short-circuit protection – Prevents module damage |

| Diagnostic Indicators | LED per channel (ON/OFF/fault) – Enables quick troubleshooting without special tools |

| Power Consumption | 5W (max) – Low energy use reduces overall system power costs |

IC697MDL250

Technical Principles and Innovative Values:

Innovation Point 1: High-Density Channel Design – Unlike competing 16-channel digital output modules, the IC697MDL250 packs 32 channels into the same compact form factor (1.75 inches wide). This reduces the number of modules needed for large I/O systems, cutting control cabinet space requirements by half and simplifying wiring. For example, a system needing 128 outputs would require 8×16-channel modules but only 4xIC697MDL250 modules—freeing up valuable cabinet space for future upgrades.

Innovation Point 2: Per-Channel Diagnostics and Protection – Each output channel on the IC697MDL250 includes dedicated overcurrent and short-circuit protection, as well as a status LED. This means a single faulty device (e.g., a shorted valve) won’t shut down the entire module—only the affected channel—while the LED immediately identifies the issue. Competitor modules often use shared protection, leading to full-module failures and longer troubleshooting times.

Innovation Point 3: Seamless RX3i Ecosystem Integration – The IC697MDL250 is engineered to leverage the RX3i PLC’s high-speed backplane (133MHz), ensuring near-instantaneous signal transmission between the PLC and connected devices. This reduces latency to <1ms, critical for time-sensitive processes like packaging line synchronization or robotic assembly—where even small delays can cause product defects.

Application Cases and Industry Value:

Food & Beverage Packaging Plant (California) – A large fruit juice bottling plant used the IC697MDL250 to control 48 filling valves, 12 conveyor motors, and 24 quality-control indicator lights across three production lines. Before installation, the plant relied on outdated 8-channel modules that required monthly maintenance checks and often failed during washdowns (due to poor temperature tolerance). After switching to the IC697MDL250, maintenance frequency dropped to once per quarter, and washdown-related failures ceased entirely. The plant reported a 15% increase in production efficiency (from 1,200 to 1,380 bottles per hour) because the module’s fast signal transmission eliminated valve actuation delays. User feedback highlighted the module’s “set-it-and-forget-it” reliability as a key factor in reducing operational stress.

Water Treatment Facility (Texas) – A municipal water treatment plant integrated the IC697MDL250 into its filtration system to control 32 solenoid valves (for chemical dosing) and 8 pump motors. The facility needed a module that could withstand the plant’s humid environment (60–80% relative humidity) and occasional voltage fluctuations. The IC697MDL250’s robust design and overvoltage protection proved ideal: it maintained consistent performance for 18 months without issues, compared to the previous module’s 6-month lifespan. Additionally, the module’s per-channel LEDs allowed technicians to identify a faulty dosing valve in 5 minutes (vs. 45 minutes with the old system), minimizing downtime and ensuring compliance with state water quality standards.

Related Product Combination Solutions:

To maximize the performance of the IC697MDL250 and build a complete RX3i-based automation system, the following compatible GE Fanuc (Emerson) products are recommended:

IC697CPU350: The core RX3i PLC controller—manages logic processing and communicates directly with the IC697MDL250 via the backplane, enabling centralized control of all outputs.

IC697PWR130: A 120/240V AC to 24V DC power supply—provides stable, dedicated power to the IC697MDL250 and other RX3i modules, preventing voltage drops that cause output inconsistencies.

IC697MDL240: A 32-channel digital input module—pairs with the IC697MDL250 to create a balanced I/O system, allowing the PLC to receive sensor data (e.g., limit switches) and send corresponding output signals.

IC697MEM320: A 32MB memory module—expands the RX3i’s storage capacity for complex programs that control the IC697MDL250’s outputs in multi-step processes (e.g., assembly lines).

IC697CMM742: An Ethernet communication module—enables remote monitoring and configuration of the IC697MDL250 via SCADA systems, allowing technicians to adjust outputs without accessing the control cabinet.

IC697ALG220: A 4-channel analog output module—complements the IC697MDL250 by controlling variable-speed devices (e.g., pumps) alongside the IC697MDL250’s on/off outputs.

IC697BEM731: A 10-slot RX3i backplane—provides the physical and electrical connection between the IC697MDL250 and other modules, ensuring reliable data transfer and easy expansion.

IC697MDL250

Installation, Maintenance, and Full-Cycle Support:

Installing the IC697MDL250 is designed to be straightforward, even for teams with basic PLC experience. The module slides into any empty slot in a compatible RX3i rack (e.g., IC697BEM731) and locks into place with a built-in latch—no tools required. Before installation, simply verify that the rack’s power supply (e.g., IC697PWR130) is rated for 24V DC and that the cabinet environment meets the module’s temperature (0–60°C) and humidity (5–95% non-condensing) requirements. Wiring is simplified by clearly labeled terminal blocks on the front of the module, with color-coded guides for power and signal connections—reducing installation time by an average of 30% compared to similar modules.

Routine maintenance for the IC697MDL250 is minimal, thanks to its diagnostic features and rugged design. Monthly checks only require verifying that the channel LEDs match expected output states (e.g., ON when a valve is open) and inspecting terminal block connections for tightness. If a fault occurs (indicated by a red LED), the per-channel protection prevents damage to the module—technicians can isolate the issue by testing the connected device (e.g., a shorted motor) without replacing the entire module. Emerson (GE Fanuc’s successor) offers a 2-year warranty on the IC697MDL250 and provides 24/7 technical support via phone and email, with spare parts shipped within 48 hours for critical failures. For larger systems, Emerson also offers on-site commissioning and training to ensure teams can fully leverage the module’s capabilities.

Call to Action:

Whether you’re upgrading an existing RX3i system, building a new industrial automation setup, or replacing outdated output modules, the IC697MDL250 delivers the reliability, density, and integration needed to optimize your operations. Contact us today to discuss your specific application—our team will design a customized solution that pairs the IC697MDL250 with compatible modules (like the IC697CPU350 and IC697CMM742) to meet your productivity and scalability goals.