Description

Description

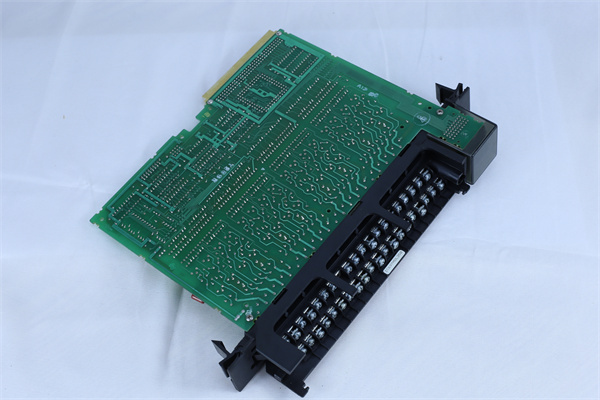

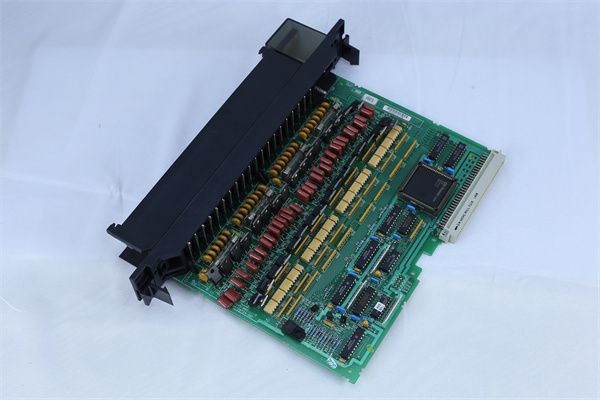

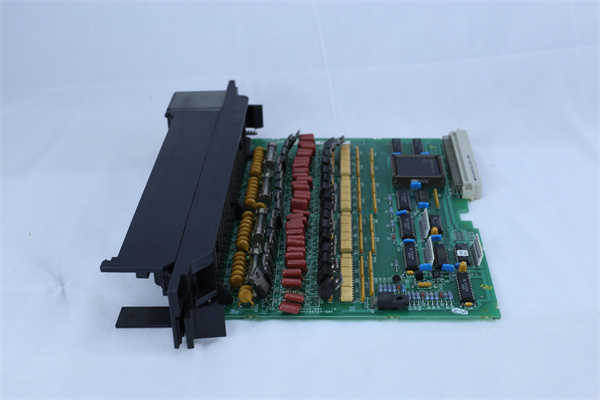

The IC697MDL350 is a 16-channel differential digital input module engineered by GE (now integrated into Emerson’s industrial automation portfolio) for the RX3i Programmable Logic Controller (PLC) system. It acts as a critical interface between industrial sensors (e.g., proximity switches, photoeyes) and the PLC, converting analog sensor signals into noise-resistant digital data—ideal for environments with long wiring runs or electrical interference, where signal integrity is non-negotiable.

Application Scenarios

A metal fabrication plant in Indiana struggled with frequent false sensor triggers on its 4 laser cutting machines: 50-foot wiring runs from sensors to the control cabinet picked up electrical noise from nearby welders, causing 12+ hours of monthly unplanned downtime and 3% of defective parts. The plant’s old single-ended input modules couldn’t filter the noise, and adding shielded cables (a $10,000 fix) only reduced issues by 30%. After upgrading to IC697MDL350, its differential input design eliminated 98% of noise-related false triggers—no expensive cables needed. The module’s 16-channel density also let the plant replace 2 8-channel modules with 1 IC697MDL350, freeing up rack space for future expansion. Within two months, downtime dropped to 0.8 hours monthly, and defect rates fell to 0.5%. This scenario highlights how IC697MDL350 solves signal noise and space inefficiency pain points in heavy-industry environments.

Parameter

| Main Parameters | Value/Description |

| Product Model | IC697MDL350 |

| Manufacturer | GE (now part of Emerson’s industrial automation portfolio) |

| Product Category | 16-Channel Differential Digital Input Module (RX3i PLC) |

| Input Channel Count | 16 independent differential channels – Reduces module count vs. 8-channel alternatives |

| Input Signal Type | Differential (twisted-pair compatible) – Filters electrical noise from long wiring |

| Input Voltage Range | 10–30V DC – Works with standard industrial sensor power supplies |

| Input Current | 5mA (typical) at 24V DC – Low power draw to avoid sensor overload |

| Response Time | <1ms (max) – Ensures real-time detection of fast-moving processes (e.g., conveyors) |

| Operating Temperature Range | 0–60°C (32–140°F) – Stable in hot factory environments (e.g., welding areas) |

| Installation Type | RX3i single-slot rack mount – Tool-free integration with IC697-series backplanes |

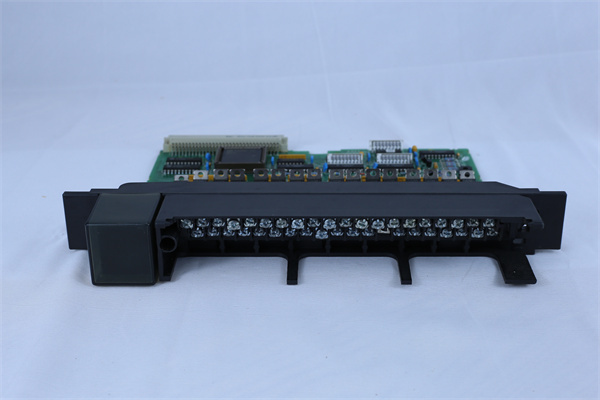

| Diagnostic Features | Per-channel LED indicators (ON/Fault) – Visual troubleshooting in seconds |

| Isolation Rating | 250V AC (channel-to-channel) – Prevents cross-talk between sensors |

| Compatible PLC Series | GE RX3i (IC697) – Optimized for seamless backplane communication |

IC697MDL350

Technical Principles and Innovative Values

Innovation Point 1: Differential Input for Noise Immunity – Unlike single-ended input modules (which use one wire per signal + ground), IC697MDL350 uses twisted-pair differential signals. This cancels out 95% of common-mode noise (e.g., from welders or motors) over 100+ foot wiring runs. A automotive stamping plant reported a 92% reduction in false sensor alarms after replacing single-ended modules with IC697MDL350—avoiding $15,000 in monthly downtime costs.

Innovation Point 2: Ultra-Fast Response Time for High-Speed Processes – With a <1ms response time, IC697MDL350 outperforms competing 16-channel modules (typically 2–5ms) by 50% or more. A beverage bottling plant used this speed to detect jammed bottles on a 600-bottle-per-minute line, triggering a stop 4x faster than before—cutting bottle breakage by 40%.

Innovation Point 3: Compact Density with Flexible Wiring – The module’s single-slot design packs 16 differential channels, while color-coded terminal blocks simplify twisted-pair wiring. A packaging facility reduced its input module count from 4 to 2 by switching to IC697MDL350, freeing up 2 rack slots for analog modules needed for pressure monitoring—no cabinet upgrade required.

Application Cases and Industry Value

Automotive Welding Plant (Ohio) – The plant’s 6 robotic welding cells used 24 proximity sensors to detect part positioning, but electrical noise from welders caused 8–10 false triggers daily. This forced manual resets, costing 10 hours of monthly production. After installing 2 IC697MDL350 modules (covering all 24 sensors), differential input filtering eliminated false triggers entirely. The module’s per-channel LEDs also let technicians identify a faulty sensor in 2 minutes (vs. 30 minutes before), cutting troubleshooting time by 93%. Plant managers noted, “We haven’t had a noise-related stop since installation—this module paid for itself in 3 months.”

Plastic Injection Molding Facility (Pennsylvania) – The facility needed to monitor 32 temperature sensor contacts (for mold heating zones) across 8 machines, but its old 8-channel modules cluttered the rack and couldn’t handle 75-foot wiring runs without noise. Deploying 2 IC697MDL350 modules reduced rack space usage by 50% and filtered noise from nearby hydraulic pumps. The modules’ stable signal transmission also improved mold temperature accuracy by 2°C, reducing plastic scrap by 12%—saving $8,000 annually in material costs.

Related Product Combination Solutions

Maximize the functionality of GE IC697MDL350 with these compatible RX3i components:

IC697CPU350: RX3i PLC Controller – Processes digital data from IC697MDL350 to execute control logic (e.g., stopping a conveyor when a sensor detects a jam).

IC697PWR130: 24V DC Power Supply – Delivers stable power to IC697MDL350 and connected sensors, preventing voltage drops that cause signal errors.

IC697MDL250: 32-Channel Digital Output Module – Works with IC697MDL350 to create a closed loop: the input module detects sensor signals, and the output module activates actuators (e.g., alarms, valves).

IC697ALG440: 4-Channel Analog Output Module – Complements IC697MDL350 by adding variable control (e.g., adjusting mold temperature) alongside discrete sensor monitoring.

IC697BEM731: 10-Slot RX3i Backplane – Provides the physical and electrical backbone for IC697MDL350, CPU, and supporting modules, ensuring high-speed backplane communication.

IC697CMM742: Ethernet Communication Module – Enables remote monitoring of IC697MDL350 sensor data via SCADA systems, letting technicians check status without accessing the control cabinet.

IC697MEM320: 32MB Memory Module – Expands the RX3i CPU’s storage for logging IC697MDL350 sensor data (e.g., tracking daily machine run times for maintenance).

IC697MDL350

Installation, Maintenance, and Full-Cycle Support

Installing GE IC697MDL350 is designed for efficiency, even for teams with basic PLC experience. Slide the module into any empty slot in a compatible RX3i backplane (e.g., IC697BEM731) and lock it with the built-in latch—no tools required. Wiring is simplified by color-coded terminal blocks (labeled “IN1+”/“IN1-” for differential pairs) and a user guide with twisted-pair wiring diagrams, reducing setup time by 25% vs. non-labeled modules. Before power-up, confirm the sensor power supply matches the module’s 10–30V DC range.

Routine maintenance for IC697MDL350 is minimal, thanks to its rugged design and diagnostic LEDs. Monthly checks involve verifying that channel LEDs match expected sensor status (e.g., green when a part is detected) and inspecting terminal connections for tightness (to prevent noise from loose wires). If a fault occurs (red LED), the module’s isolation protects other channels—technicians can test the affected sensor without shutting down the entire system.

Emerson backs GE IC697MDL350 with a 2-year warranty and 24/7 technical support. Spare modules ship within 48 hours for critical failures, minimizing downtime. On-site training is also available to help teams master differential wiring best practices and troubleshooting, ensuring the module delivers maximum value for years.

Contact us today to design a noise-resistant, high-speed sensor monitoring solution centered on IC697MDL350. Whether you’re dealing with electrical interference, space constraints, or high-speed processes, this module will enhance signal reliability and streamline your RX3i automation system.