Description

Product Overview

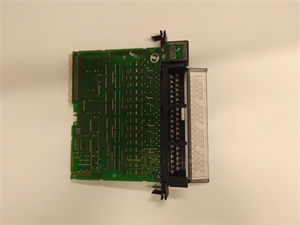

The GE IC697MDL750 is a discrete output module that belongs to the renowned Series 90 – 70 of GE Fanuc’s industrial automation offerings. In industrial control systems, discrete output modules like the GE IC697MDL750 are essential components, acting as the bridge between the control logic of a Programmable Logic Controller (PLC) and the external devices that need to be actuated.

This module is equipped with 32 output points, organized into four groups of eight channels each. With a nominal operating voltage range of 24 – 48 VDC, it can efficiently power and control a wide array of industrial devices. From solenoids that control the flow of fluids in pipelines to motor starters that initiate the operation of electric motors and indicators that provide visual status feedback, the GE IC697MDL750 plays a crucial role. Its design allows for seamless integration into complex automation setups, ensuring reliable and accurate control over industrial processes. By providing a stable and consistent output, it enables the smooth operation of various industrial machinery and systems, enhancing productivity and reducing the risk of errors in industrial operations.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC697MDL750 |

| Manufacturer | GE Fanuc |

| Product Type | Discrete Output Module |

| Rated Voltage | 24 – 48 VDC |

| Output Voltage Range | 20 – 60 VDC |

| Output Current | 0.5 amps per point; 2 amps per group |

| Number of Outputs | 32 (4 groups of 8 channels) |

| Current Required from 5V Bus | 0.25 amp |

| Inrush Current | 10 amps maximum for 20 ms |

| Response Time (On/Off) | 1 ms maximum |

| Isolation Voltage | 1500 volts between field side and logic side; 500 volts between groups |

| Wiring Configuration | Positive logic |

| Nominal Output Voltage | 24 / 48 VDC |

| Maximum Output Voltage Drop | 1.0 V |

| Off – State Leakage | 1 ma maximum |

| Dimensions | 200 × 150 × 20 mm |

| Weight | 1.8 kg |

IC697MDL750

Main Features and Advantages

High – Capacity Output

Each output point of the GE IC697MDL750 can handle up to 0.5 amps, with a group capacity of 2 amps. This high – current – handling ability makes it suitable for driving power – hungry industrial devices. Whether it’s powering large solenoids or motor starters, the module can meet the demands without performance degradation, ensuring the reliable operation of connected equipment.

Wide Voltage Tolerance

Operating within a voltage range of 20 – 60 VDC, the module can adapt to different power supply conditions in industrial settings. This wide voltage tolerance is beneficial as it reduces the need for additional voltage regulation equipment in many cases. It can function effectively even when there are minor fluctuations in the power supply, providing stability to the overall control system.

Fast Response Time

With a response time of 1 ms maximum for both on and off operations, the GE IC697MDL750 enables rapid control actions. In applications where real – time response is crucial, such as high – speed manufacturing processes or safety – critical systems, this fast response ensures that commands are executed promptly. It allows for quick changes in the state of output devices, enhancing the overall efficiency and safety of industrial operations.

Robust Isolation

Featuring an isolation voltage of 1500 volts between the field side and logic side and 500 volts between groups, the module provides excellent electrical isolation. This isolation protects the control system’s sensitive logic components from electrical noise and transients that may be present in the industrial environment. It also helps in preventing electrical interference between different output groups, ensuring the reliable operation of the module and the connected devices.

User – Friendly Configuration

The GE IC697MDL750 can be configured using the configuration function of MS – DOS or Windows programming software. Connections can be made via Ethernet TCP/IP or through the SNP port, and the programming device can be an IBM XT, AT, PS/2, or compatible PC. This ease of configuration allows system integrators and operators to customize the module’s settings according to the specific requirements of the industrial application without the need for complex hardware modifications.

IC697MDL750

Application Field

Manufacturing Industry

In manufacturing plants, the GE IC697MDL750 is extensively used. For example, in an automotive assembly line, it can control the solenoids that operate pneumatic or hydraulic cylinders. These cylinders are responsible for tasks like moving parts into position, clamping components for welding or assembly, and controlling the movement of conveyor belts. The module’s fast response time ensures that these operations occur in a timely and coordinated manner, optimizing the production process and increasing throughput.

Process Industries

Industries such as chemical and food processing rely on the GE IC697MDL750 for process control. In a chemical plant, it can be used to control motor starters that drive pumps for transferring chemicals. The module’s high – capacity output can handle the power requirements of these pumps, and its wide voltage tolerance ensures stable operation even in the presence of electrical noise from other equipment. In a food processing facility, it can control indicators that show the status of different processing stages, such as the filling level of containers or the operation status of packaging machines.

Power Generation

In power generation plants, the module plays a role in controlling various auxiliary systems. It can be used to control the solenoids that operate valves in the cooling water system, ensuring proper water flow to cool down generators. The GE IC697MDL750‘s robust isolation features protect the control system from the high – voltage and high – current environments present in power plants. Its reliable operation is crucial for maintaining the stable operation of the power generation process, minimizing downtime, and ensuring a consistent power supply to consumers.

Related Products

- IC697MDL730: Another discrete output module in the GE Fanuc Series 90 – 70. It has a different number of output points compared to the IC697MDL750. While the IC697MDL750 has 32 output points, the IC697MDL730 may have fewer, which can be more suitable for applications with less demanding output requirements.

- IC693MDL940: This is a discrete input/output module. Unlike the IC697MDL750 which is only for output, the IC693MDL940 can handle both input and output functions. It can be used in applications where there is a need to both sense external signals and provide output control, offering more versatility in certain industrial setups.

- IC695MDL645: A discrete output module with different voltage ratings. If the application requires a different operating voltage range than what the IC697MDL750 offers, the IC695MDL645 might be a better choice. It can be used in systems where the power supply characteristics are different from those suitable for the IC697MDL750.

- IC697ALG222: An analog output module, which is different from the discrete nature of the IC697MDL750. It is used for applications that require the output of continuous analog signals, such as controlling the speed of variable – speed drives or regulating the flow rate of a process by adjusting a control valve’s position.

- IC697CHS790: A carrier module that can house multiple I/O modules, including the IC697MDL750. It provides a physical and electrical connection framework for organizing and integrating different modules in a control system, enhancing the modularity and expandability of the overall setup.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IC697MDL750, carefully verify the power supply voltage to ensure it falls within the 24 – 48 VDC range. The installation location should be clean, dry, and free from excessive heat and humidity. Mount the module securely in a suitable enclosure, following the provided mechanical mounting guidelines. Ensure that all wiring connections are properly made, with appropriate wire gauges used to handle the expected current loads. Also, check for any physical damage to the module before installation.

Maintenance recommendations: Regularly inspect the GE IC697MDL750 for signs of overheating, such as discoloration of the module’s surface or abnormal heat generation. Monitor the output voltages and currents using appropriate measuring instruments to ensure they are within the specified ranges. Check the status of the LED indicators on the module, which show the on – off state of each output point. If any output points are not functioning correctly, use the programming software to diagnose and troubleshoot the issue. Clean the module periodically to remove dust and dirt, as these can affect the module’s performance over time.

Product Guarantee

GE Fanuc offers a comprehensive product guarantee for the GE IC697MDL750. The module is manufactured to high – quality standards, with strict quality control measures in place during the production process. In case of any manufacturing defects, GE Fanuc provides a warranty that covers repair or replacement of the module within the specified warranty period. Their technical support team is readily available to assist customers with any installation, configuration, or troubleshooting issues. Whether it’s answering technical queries or providing guidance on maintenance, GE Fanuc’s commitment to customer satisfaction ensures that users can rely on the GE IC697MDL750 for their industrial automation needs with confidence.