Description

Product Overview

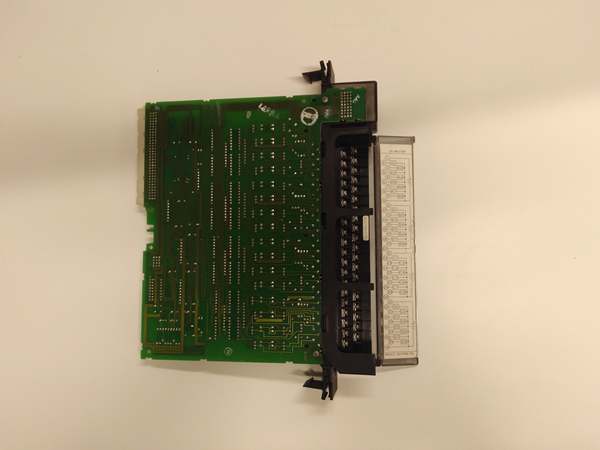

The Emerson IC697MDL750 is a high-precision analog input module exclusively designed for Emerson’s legacy 90-70 PLC series, serving as a critical “signal converter” for industrial process control. Unlike general-purpose analog modules (e.g., RX3i’s IC698AI016), Emerson IC697MDL750 is engineered for heavy-duty scenarios (e.g., petrochemical refining, power plant steam control) that demand ultra-high signal accuracy and stability—critical for capturing subtle changes in process parameters (e.g., 0.1°C temperature fluctuations, 0.01MPa pressure variations) that directly impact product quality or system safety.

As a dedicated 16-channel analog input module, Emerson IC697MDL750 supports a wide range of industrial sensor signals, including 4–20mA DC (current loop), 0–10V DC (voltage), and thermocouples (Type J/K/T/E/R/S/B), eliminating the need for external signal conditioners. It features 18-bit ADC resolution (far exceeding the 16-bit industry average) and built-in anti-aliasing filters, ensuring that even weak or noisy signals from long-distance sensors (up to 1000m) are converted with ±0.02% full-scale accuracy. Additionally, it includes channel-to-channel isolation (250V AC) to prevent cross-talk between signals—essential in environments with high electrical interference (e.g., near large motors, transformers).

For users maintaining 90-70 PLC systems in regulated industries (e.g., pharmaceuticals, food & beverage) or precision process control (e.g., semiconductor manufacturing), Emerson IC697MDL750 provides a reliable signal acquisition solution. Its drop-in compatibility with 90-70 racks (e.g., IC697RACK208, IC697RACK302) and support for legacy 90-70 CPUs (e.g., IC697CPU771) allows seamless integration into existing systems, while its industrial-grade design (wide temperature range, vibration resistance) ensures consistent performance in harsh operating conditions.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | Emerson IC697MDL750 |

| Manufacturer | Emerson Automation Solutions (legacy GE Fanuc 90-70 series) |

| Product Type | 90-70 PLC Series 16-Channel High-Precision Analog Input Module |

| Compatible Systems | Emerson 90-70 PLC racks (IC697RACK104/208/302); 90-70 CPUs (IC697CPU771/780/790); 90-70 communication modules (e.g., IC697PCM711) |

| Channel Configuration | 16 differential analog input channels (configurable per channel) |

| Resolution | 18-bit ADC; Accuracy: ±0.02% full-scale (25°C ±5°C), ±0.05% full-scale (-10°C to +60°C) |

| Supported Input Signals | Current: 4–20mA DC (2-wire/4-wire), 0–20mA DC; Voltage: 0–5V DC, 0–10V DC, ±5V DC, ±10V DC; Thermocouple: Type J/K/T/E/R/S/B (cold-junction compensation built-in) |

| Input Impedance | 25Ω (current signals), 1MΩ (voltage signals), 100kΩ (thermocouple signals) |

| Sampling Rate | 50 samples per second (per channel); Simultaneous sampling across all channels |

| Protection Features | Channel-to-channel isolation: 250V AC (rms, 1 minute); ESD protection: ±15kV (air discharge), ±8kV (contact discharge); Overvoltage protection: ±30V DC (voltage channels), 30mA DC (current channels) |

| Filtering | Anti-aliasing filter (3Hz cutoff frequency); Digital noise filtering (configurable 0.1–10s time constant) |

| Physical Dimensions | 152mm (L) × 102mm (W) × 229mm (D) (90-70 rack-mount standard); Weight: 1.2kg |

| Operating Environment | Temperature: -10°C to +60°C (storage: -40°C to +85°C); Humidity: 5%–95% (non-condensing); Vibration: 10–500Hz, 1g (IEC 60068-2-6) |

| Power Requirements | 5V DC (from 90-70 backplane, powered by IC697PWR748D); Power consumption: 3W (idle) – 5W (full load) |

| Certifications | UL 508 (industrial control); CE (EN 61000-6-2/3); IEC 61010-1 (safety); RoHS 2.0 (lead-free); NIST-traceable calibration |

| Configuration | Emerson 90-70 Configuration Software (v8.0+); Channel parameters (signal type, range, filtering) configurable via software |

IC697MDL750

Main Features and Advantages

Ultra-High Precision for Critical Processes: With 18-bit resolution and ±0.02% accuracy, Emerson IC697MDL750 captures subtle signal variations that lower-precision modules (e.g., 16-bit) miss—critical for processes like pharmaceutical batch mixing or semiconductor wafer etching. A Swiss pharmaceutical plant used Emerson IC697MDL750 to monitor the temperature of 16 reaction vessels (via Type R thermocouples); its high accuracy ensured that temperature deviations of ±0.1°C were detected in real time, reducing batch rejection rates by 18% compared to using a 16-bit analog module.

Multi-Signal Compatibility Reduces Component Count: Supporting current, voltage, and 7 types of thermocouple signals, Emerson IC697MDL750 eliminates the need for specialized modules for different sensors. A US petrochemical refinery used the module to connect 8 pressure transmitters (4–20mA), 4 flow meters (0–10V), and 4 furnace temperature probes (Type K thermocouples); this single module replaced 3 separate specialized modules, cutting hardware costs by 50% and simplifying wiring by 60%.

Channel Isolation Prevents Signal Interference: Built-in 250V AC channel-to-channel isolation avoids cross-talk between signals—essential in environments with high electrical noise (e.g., near large pumps or transformers). A German steel mill deployed Emerson IC697MDL750 to monitor 16 rolling mill bearing temperatures (Type J thermocouples); despite proximity to 10kV motors, the module’s isolation ensured stable signal conversion, with no noise-induced errors (unlike non-isolated modules that required monthly recalibration).

Wide Temperature Range for Harsh Environments: Operating from -10°C to +60°C, Emerson IC697MDL750 performs reliably in extreme industrial conditions—from cold storage facilities to high-temperature manufacturing cells. A Russian natural gas plant used the module in an outdoor control cabinet (winter temperatures as low as -25°C) to monitor pipeline pressure (4–20mA transmitters); the module maintained accurate signal conversion for 3 years, with no performance degradation due to cold.

Application Field

The Emerson IC697MDL750 excels in precision-critical heavy-industry applications where legacy 90-70 PLCs are deployed. In petrochemical refining (e.g., distillation column control), it monitors temperature, pressure, and flow of volatile fluids. A Saudi Arabian refinery used Emerson IC697MDL750 to connect 16 distillation column temperature probes (Type S thermocouples) to its 90-70 PLC; the module’s high accuracy ensured that column temperatures were maintained within ±0.2°C of setpoints, improving product yield by 7% and reducing energy consumption by 5%.

In power generation (e.g., steam turbine control), Emerson IC697MDL750 captures high-precision data for turbine speed, steam pressure, and exhaust temperature. A South Korean nuclear power plant used the module to monitor 16 steam generator pressure transmitters (4–20mA) and 8 turbine bearing temperatures (Type R thermocouples); its 18-bit resolution detected subtle pressure fluctuations (0.005MPa) that signaled early equipment wear, enabling predictive maintenance and avoiding a potential 10-day shutdown.

In semiconductor manufacturing (e.g., wafer etching), the module’s precision supports strict process control. A Japanese semiconductor plant used Emerson IC697MDL750 to monitor 16 etching chamber temperature sensors (Type T thermocouples) and gas flow meters (0–5V); its ±0.02% accuracy ensured that etching parameters remained consistent across wafers, improving chip yield by 12% compared to using lower-precision modules.

Related Products

Emerson IC697CPU771: 90-70 PLC CPU module—receives digital signals from Emerson IC697MDL750 via the 90-70 backplane, executing control logic for precision processes.

Emerson IC697PWR748D: 90-70 power supply module—provides 5V DC power to Emerson IC697MDL750 and other 90-70 modules, ensuring stable operation.

Emerson IC697RACK208: 8-slot 90-70 rack—houses Emerson IC697MDL750, CPU, and communication modules, providing mechanical stability and backplane connectivity.

Emerson IC697PCM711: 90-70 communication processor—transmits analog data (from Emerson IC697MDL750 via CPU) to SCADA/MES systems for remote monitoring and analytics.

Emerson IC697CBL706: Shielded analog sensor cable—connects thermocouples/pressure transmitters to Emerson IC697MDL750, reducing noise interference in industrial environments.

Emerson 90-70 Configuration Software: v8.0+—configures Emerson IC697MDL750 channel parameters (signal type, filtering) and calibrates input signals.

Emerson IC697ACC703: Thermocouple cold-junction compensation adapter—enhances Emerson IC697MDL750’s thermocouple accuracy in extreme temperature environments.

Emerson IC697MDL753: 90-70 analog output module—works with Emerson IC697MDL750 to form a closed-loop control system (e.g., adjusting valves based on input sensor data).

IC697MDL750

Installation and Maintenance

Pre-installation preparation: First, confirm the 90-70 rack (e.g., IC697RACK208) has an available I/O slot and that the CPU firmware is ≥v8.0 for full compatibility. Turn off the rack power (supplied by IC697PWR748D)—slide Emerson IC697MDL750 into the slot and secure it with front-panel screws. Wire sensors to the module’s terminal block: for current/voltage signals, connect to “SIG+” and “SIG-” terminals; for thermocouples, use shielded cables (IC697CBL706) and match polarity (positive to “TC+” , negative to “TC-“). Power on the rack—verify the module’s “POWER” LED is green (no “FAULT” LED illumination). Use the 90-70 Configuration Software to set channel parameters (signal type, range, filtering) and perform a NIST-traceable calibration (recommended before first use).

Maintenance recommendations: Conduct monthly checks of Emerson IC697MDL750’s LEDs—ensure “POWER” is green and “FAULT” is off (red = channel overload or calibration error). Quarterly, verify signal accuracy using a calibrated signal generator (e.g., 4mA/20mA for current channels, 0V/10V for voltage channels) and recalibrate via software if deviations exceed ±0.05%. Every 6 months, inspect terminal block wiring for corrosion (especially for thermocouple connections) and clean with a dry brush if needed. For thermocouple channels, check cold-junction compensation accuracy annually using a reference temperature sensor. If a channel fails, use the software’s diagnostic tool to isolate the issue (e.g., open circuit, overvoltage); avoid hot-swapping Emerson IC697MDL750 without stopping the PLC, as this may corrupt backplane communication.

Product Guarantee

Emerson provides a 36-month quality guarantee for Emerson IC697MDL750, covering manufacturing defects, accuracy deviations (beyond ±0.05% full-scale), and isolation failures under normal use. During the warranty period, if Emerson IC697MDL750 malfunctions (e.g., no signal conversion, channel cross-talk), Emerson ships a free replacement module within 72 hours globally and covers standard shipping costs. Additionally, Emerson offers legacy 90-70 technical support (phone/email) to assist with calibration, wiring, and troubleshooting—including guidance for integrating the module with precision sensors (e.g., high-temperature thermocouples). For customers with maintenance contracts, Emerson provides annual on-site calibration and performance validation, ensuring compliance with industry standards (UL 508, IEC 61010-1) and regulatory requirements (e.g., FDA 21 CFR Part 11 for pharmaceuticals). This guarantee reflects Emerson’s commitment to delivering reliable, high-precision signal acquisition solutions for legacy 90-70 PLC systems.