Description

Product Overview

The Emerson IC697PCM711 is a high-performance communication processor module exclusively designed for Emerson’s legacy 90-70 PLC series, serving as the “network hub” for seamless data exchange between 90-70 PLC systems and external industrial networks. Unlike basic communication modules (e.g., RX3i’s IC698CRE030-EE), Emerson IC697PCM711 is engineered for heavy-duty industrial scenarios (e.g., power generation, steel manufacturing) that demand multi-protocol support, high data throughput, and long-term reliability—critical for integrating legacy 90-70 PLCs into modern industrial automation ecosystems.

As a dedicated communication processor, Emerson IC697PCM711 supports a suite of industrial protocols, including Modbus TCP/IP, Ethernet/IP (scanner mode), and Profinet (compatible with third-party industrial devices), enabling bidirectional data transmission between the 90-70 CPU (e.g., IC697CPU771) and upper-layer systems (SCADA, MES, cloud platforms). It features dual 10/100Mbps Ethernet ports for network redundancy (ring topology support), eliminating single points of failure in mission-critical applications where downtime could incur significant losses. Additionally, it includes a built-in diagnostic interface (via front-panel LEDs and software tools) to monitor network status, protocol health, and connection stability—simplifying troubleshooting for maintenance teams managing legacy infrastructure.

For users maintaining or upgrading 90-70 PLC systems (common in industries with 10+ year equipment lifecycles), Emerson IC697PCM711 provides a cost-effective path to modernize communication capabilities without replacing the entire PLC. Its drop-in compatibility with 90-70 racks (e.g., IC697RACK208, IC697RACK302) and support for legacy wiring reduce retrofitting costs, while its industrial-grade design (wide temperature range, vibration resistance) ensures consistent performance in harsh environments.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | Emerson IC697PCM711 |

| Manufacturer | Emerson Automation Solutions (legacy GE Fanuc 90-70 series) |

| Product Type | 90-70 PLC Series Multi-Protocol Communication Processor Module |

| Compatible Systems | Emerson 90-70 PLC racks (IC697RACK104/208/302); 90-70 CPUs (IC697CPU771/780/790); 90-70 I/O modules (e.g., IC697MDL240) |

| Network Interfaces | 2x 10/100Mbps RJ45 ports (auto-negotiation, full/half-duplex); 1x RS-232 port (for local configuration/debugging) |

| Supported Protocols | Modbus TCP/IP (server/client, max 64 connections); Ethernet/IP (scanner/adapter mode); Profinet (v2.3, compatible with IRT); SNMP v3 (for network management) |

| Data Throughput | Max 80Mbps (full-duplex); Latency: ≤3ms (Modbus TCP request/response); Data buffer: 256KB (for burst data handling) |

| Memory | 512MB RAM (protocol processing); 1GB flash (firmware/storage of configuration files) |

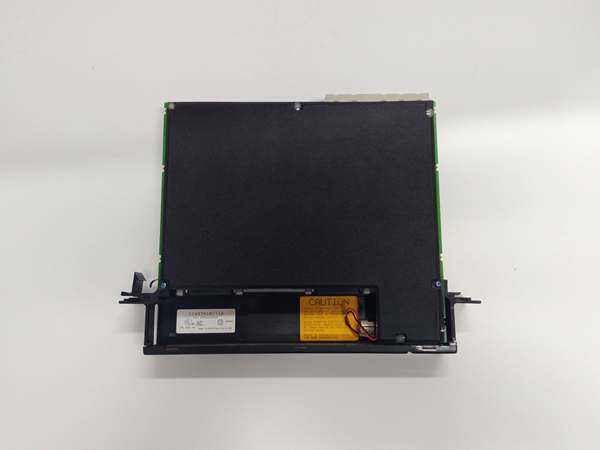

| Physical Dimensions | 152mm (L) × 102mm (W) × 229mm (D) (90-70 rack-mount standard); Weight: 1.5kg |

| Operating Environment | Temperature: -20°C to +65°C (storage: -40°C to +85°C); Humidity: 5%–95% (non-condensing); Vibration: 10–500Hz, 1.5g (IEC 60068-2-6) |

| Power Requirements | 5V DC (from 90-70 backplane, powered by IC697PWR748D); Power consumption: 4W (idle) – 7W (full load) |

| Certifications | UL 508 (industrial control); CE (EN 61000-6-2/3); IEC 61010-1 (safety); RoHS 2.0 (lead-free); IEEE 802.3 (Ethernet compliance) |

| Configuration | Emerson 90-70 Configuration Software (v9.0+); Web-based management interface (for remote protocol setup) |

| Redundancy | Supports network redundancy (ring topology, recovery time ≤50ms); Backplane communication redundancy (with dual CPUs) |

IC697PCM711

Main Features and Advantages

Multi-Protocol Support for Ecosystem Integration: Emerson IC697PCM711 eliminates the need for multiple single-protocol modules by supporting Modbus TCP/IP, Ethernet/IP, and Profinet—critical for connecting 90-70 PLCs to mixed-vendor systems. A US power plant used Emerson IC697PCM711 to integrate its 90-70 PLC (controlling turbine generators) with a Siemens SCADA system (via Profinet) and a local HMI (via Modbus TCP); the module’s multi-protocol capability reduced hardware costs by 40% compared to using three separate communication modules.

Dual-Port Redundancy for Uninterrupted Communication: Equipped with two Ethernet ports, Emerson IC697PCM711 supports ring topology to avoid network downtime from cable failures or switch malfunctions. A German steel mill deployed the module in a hot rolling mill’s 90-70 PLC system; when a forklift accidentally damaged an Ethernet cable, the module automatically switched to the redundant port within 30ms—preventing a 2-hour production halt that would have cost €150,000.

High Throughput for Large-Scale Data Transfer: With 80Mbps full-duplex throughput and 256KB data buffer, Emerson IC697PCM711 handles burst data from hundreds of I/O points (e.g., temperature sensors, pressure transmitters) without latency. A Chinese petrochemical plant used the module to transmit real-time process data (from 500+ analog sensors) from its 90-70 PLC to a cloud-based MES; the module’s buffer prevented data loss during peak traffic, ensuring 99.99% data integrity for production analytics.

Legacy Compatibility with Modern Upgrades: As a drop-in module for 90-70 racks, Emerson IC697PCM711 works with existing 90-70 CPUs and I/O modules, while enabling integration with modern systems (e.g., cloud platforms via Modbus TCP). A Japanese automotive parts manufacturer upgraded 8 legacy 90-70 PLCs with Emerson IC697PCM711; no rack modifications or CPU firmware updates were needed, and the modules enabled remote monitoring of assembly lines—reducing on-site maintenance visits by 30%.

Application Field

The Emerson IC697PCM711 excels in heavy-industry applications where legacy 90-70 PLCs require reliable, multi-protocol communication. In power generation (e.g., coal-fired power plants), it connects 90-70 PLCs to SCADA systems for real-time monitoring of boiler pressure, turbine speed, and grid frequency. A South Korean power plant used Emerson IC697PCM711 to link its 90-70 PLC (controlling a 500MW turbine) to a national grid SCADA system via Modbus TCP; the module’s redundancy ensured uninterrupted data transmission, even during local network outages.

In steel manufacturing (e.g., cold rolling mills), Emerson IC697PCM711 integrates 90-70 PLCs with robotic arms and quality inspection systems. A Brazilian steel mill deployed the module to connect its 90-70 PLC to a Fanuc robot (via Ethernet/IP) and a laser thickness gauge (via Profinet); the module’s low latency (≤3ms) enabled synchronized control of rolling speed and robot positioning, improving product uniformity by 15%.

In oil & gas (e.g., offshore platforms), the module’s rugged design withstands harsh marine environments. A Norwegian offshore platform used Emerson IC697PCM711 to connect its 90-70 PLC (controlling wellhead valves) to an onshore SCADA system; the module’s wide temperature range (-20°C to +65°C) and vibration resistance (1.5g) ensured stable communication in storm conditions, reducing unplanned downtime by 25%.

Related Products

Emerson IC697CPU771: 90-70 PLC CPU module—exchanges data with Emerson IC697PCM711 via the 90-70 backplane, executing control logic for industrial processes.

Emerson IC697PWR748D: 90-70 power supply module—provides 5V DC power to Emerson IC697PCM711 and other 90-70 modules, ensuring stable operation.

Emerson IC697RACK208: 8-slot 90-70 rack—houses Emerson IC697PCM711, CPU, and I/O modules, providing mechanical stability and backplane connectivity.

Emerson IC697MDL753: 90-70 analog I/O module—collects sensor data (e.g., pressure, temperature) and sends it to Emerson IC697PCM711 via the CPU for transmission to SCADA.

Emerson IC697CBL705: Shielded Ethernet cable—connects Emerson IC697PCM711 to industrial switches, reducing electrical noise in heavy-industry environments.

Emerson 90-70 Configuration Software: v9.0+—configures protocols (Modbus TCP/IP, Ethernet/IP) and monitors network status for Emerson IC697PCM711.

Emerson IC697ACC702: 90-70 rack surge protector—protects Emerson IC697PCM711 from voltage spikes (common in power plants/steel mills) to prevent damage.

Emerson IC697CMM742: 90-70 serial communication module—complements Emerson IC697PCM711 by adding RS-485 ports for legacy serial devices (e.g., old HMIs).

IC697PCM711

Installation and Maintenance

Pre-installation preparation: First, confirm the 90-70 rack (e.g., IC697RACK208) has an available I/O slot (not the dedicated power/CPU slots) and that the CPU firmware is ≥v7.0 for full protocol support. Turn off the rack power (supplied by IC697PWR748D)—slide Emerson IC697PCM711 into the slot and secure it with front-panel screws. Connect one or both Ethernet ports to the industrial network using shielded cables (IC697CBL705); for redundancy, configure the ports into a ring topology via the 90-70 Configuration Software. Power on the rack—verify the module’s “POWER” LED is green and “LINK” LEDs (for Ethernet ports) are steady green (blinking indicates active data transfer).

Maintenance recommendations: Conduct weekly checks of Emerson IC697PCM711’s LEDs—ensure “POWER” is green, “FAULT” is off (red = protocol/network error), and “LINK” LEDs are active. Monthly, use the web-based management interface to monitor protocol status (e.g., Modbus TCP connection count, Ethernet/IP scanner status) and update firmware (if needed) to patch security vulnerabilities. Every 6 months, clean the module’s air vents with compressed air (in dusty environments like steel mills) to prevent overheating. If a network fault occurs, use the software’s diagnostic tool to trace packet loss or protocol mismatches; avoid hot-swapping Emerson IC697PCM711 without stopping the PLC, as this may corrupt backplane communication.

Product Guarantee

Emerson provides a 30-month quality guarantee for Emerson IC697PCM711, covering manufacturing defects, protocol malfunctions (e.g., failed Modbus TCP connections), and network interface failures under normal use. During the warranty period, if Emerson IC697PCM711 malfunctions (e.g., no Ethernet link, unresponsive protocol stack), Emerson ships a free replacement module within 72 hours globally and covers standard shipping costs. Additionally, Emerson offers legacy 90-70 technical support (phone/email) to assist with protocol configuration and troubleshooting—including guidance for integrating the module with modern systems (e.g., cloud platforms). For customers with legacy maintenance contracts, Emerson provides annual on-site checks—verifying network performance, updating firmware, and ensuring compliance with industrial standards (UL 508, IEC 61010-1). This guarantee reflects Emerson’s commitment to extending the value of legacy 90-70 PLC infrastructure through reliable communication solutions.